Reinforcement cage cement plaster pile casing for sea reclamation fill geological basement and construction process thereof

A steel skeleton and cement mortar technology, which is applied in the direction of basic structure engineering, construction, sheet pile walls, etc., can solve the problems that affect the construction period, easily cause collapse, and the foundation of the foundation pit is not stable enough, so as to prevent the outflow of mud, control overfilling, The effect of preventing collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

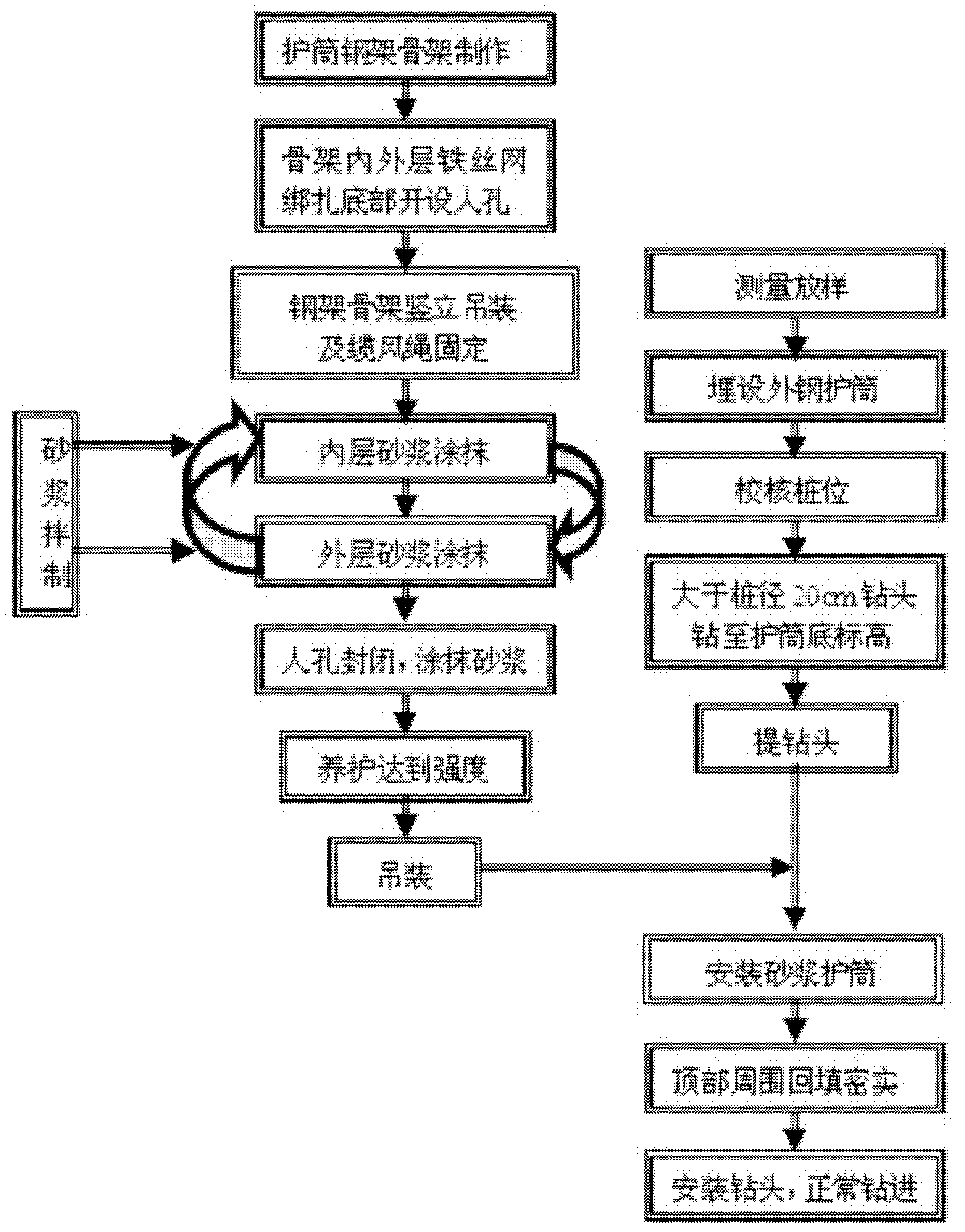

[0022] The present invention will be further described in conjunction with the accompanying drawings, and the manufacturing technology and process flow of this device are very clear to those skilled in the art.

[0023] 1. Fabrication of reinforced skeleton cement mortar casing

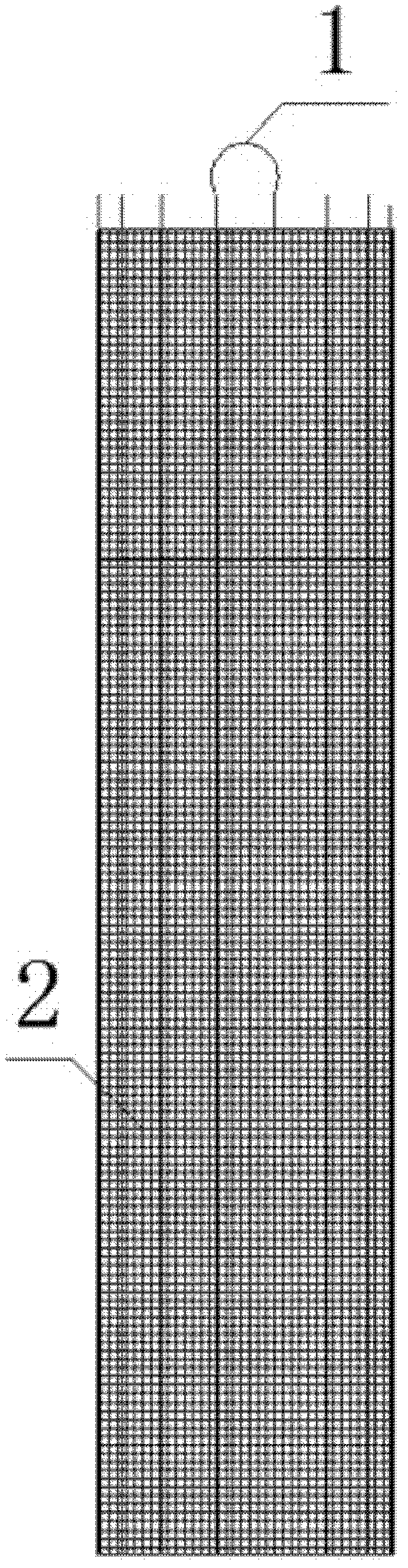

[0024] 1) Construction and production of steel skeleton

[0025] Generally, the bored pile with a diameter of 1.5m is designed, and the circumferential skeleton reinforcement of the reinforced skeleton cement mortar casing adopts Φ25 threaded steel bars, which are arranged along the length of the casing from 1.7m to 2m, and double-sided lap welding is adopted; 16 longitudinal skeleton reinforcements are used Φ16 threaded steel bars are uniformly welded on the outer side of the hoop skeleton steel bars; the tops of two longitudinal steel bars in any diameter direction are welded with lifting rings. The length of the steel skeleton is considered according to the ground elevation of the drilling platfor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com