A method of absorbing material energy and its application

A material energy and energy technology, applied in the fields of refrigeration technology, thermal energy utilization technology and power generation technology, can solve the problem of consuming large energy (electricity, impossible to generate electricity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

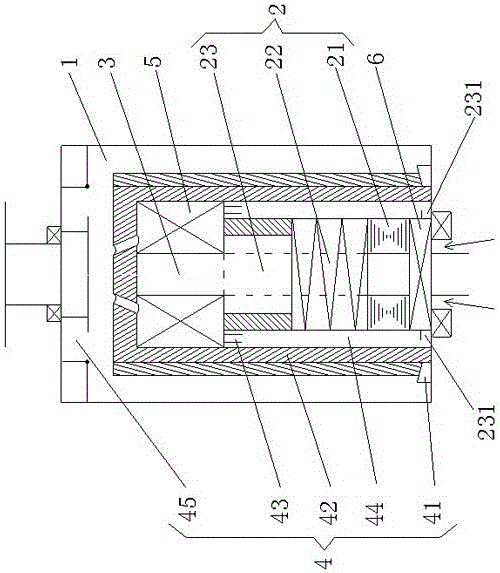

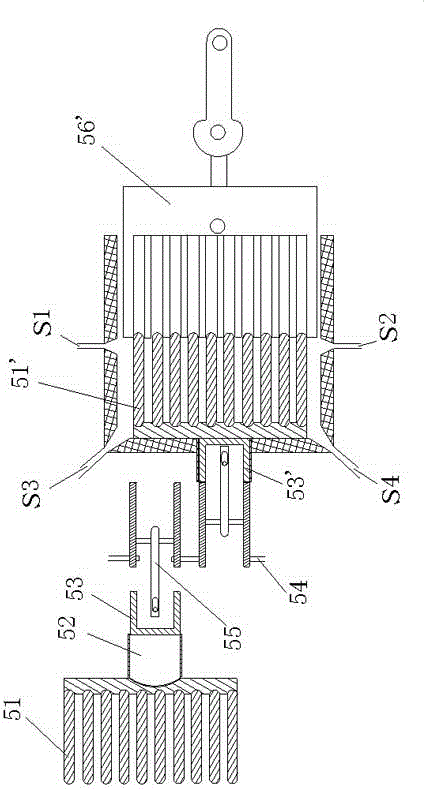

[0054] Such as figure 1 , figure 2 , image 3 The shown self-cooling equipment includes an evaporation chamber 1, a compression system 2, a condensation chamber 3, a refrigerant circulation system 4, a thermodynamic system, and a storage battery 6; the thermodynamic system includes a set of thermodynamic mechanisms 5, Thermodynamic device of thermodynamic mechanism 5'.

[0055] Described thermodynamic mechanism 5 comprises: 100 copper condensing pipes 51, cylinder 52, piston 53, crank 54, connecting rod 55; 52 and piston 53 form a fully enclosed space; 100 condensation pipes 51 are all completely installed in the condensation chamber 3, and are not communicated with the condensation chamber, so that the reaction medium in the condensation pipe 51 will not flow into the condensation chamber 3 except the condensation pipe 51 space, the reaction medium in the same condensation chamber 3 will not flow into the condensation pipe 51, and at the same time, it can ensure sufficien...

Embodiment 2

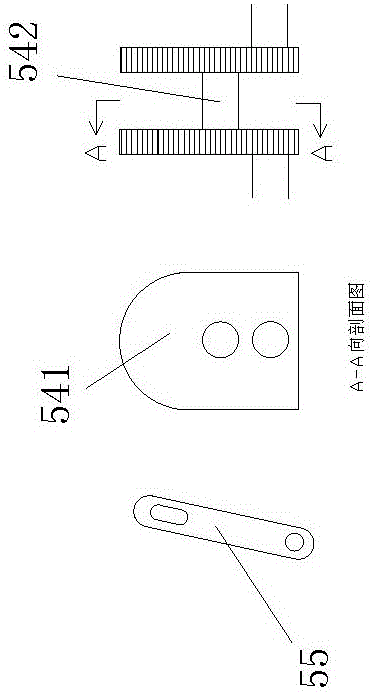

[0099] Such as figure 1 , image 3 , Figure 4 As shown, the thermal power mechanism of Embodiment 1 can also be directly connected to the cylinder 57 by the heat collection chamber 23. When the piston 53 reaches the closest point, K1 is opened, and when the arc section of the cam 541 is turned out of the piston 53, K1 is closed, and the high temperature The high-pressure liquid ammonia vaporizes quickly, and turns into high-pressure gaseous ammonia, which quickly acts on the piston to move to the farthest point; when the piston 53 reaches the farthest point, K2 opens, and the piston 53 discharges the gaseous ammonia out of the cylinder 57, and returns to the compression mechanism through the return pipe 46 . On the other hand, the heat collecting chamber 23 communicates with the preparation chamber 45 through 100 condensation pipes 58 placed in the cooling chamber 44 .

[0100] Such as Figure 5 As shown, with regard to the above-mentioned embodiment, the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com