Centrifugal air compressor and control method and system thereof

A technology of centrifugal air compressor and control method, which is applied in the direction of pump control, mechanical equipment, non-variable pump, etc., can solve the problems of low reliability and manpower consumption, and achieve the effect of ensuring reliability and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

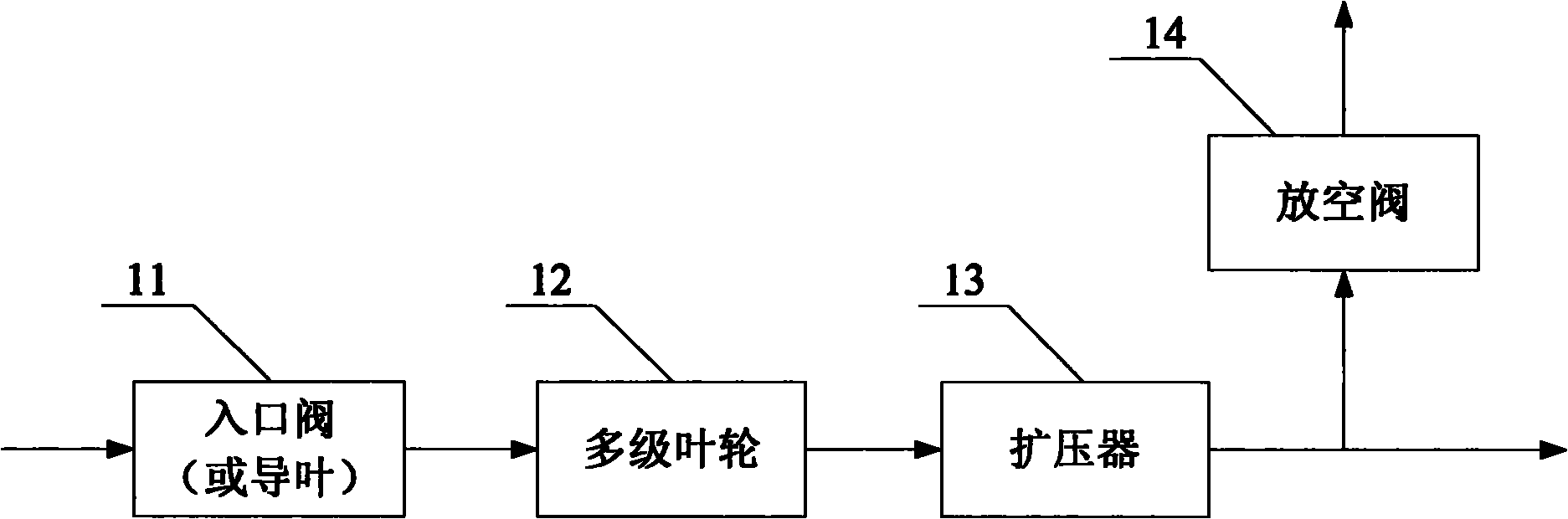

[0061] The invention provides a new scheme for controlling the centrifuge air compressor: after receiving the flow or pressure value specified by the user, the centrifugal air compressor is controlled to work according to the corresponding state, and the measured pressure and flow are collected in real time, and will The calculated flow value is determined as the reference flow, and compared with the measured flow, and the opening value of the vent valve is adjusted according to the comparison result, so that the measured flow is as close as possible to the reference flow. During this process, the user only needs to input the required flow or pressure value, and there is no need to adjust the opening of the vent valve based on experience, which saves manpower and ensures reliability.

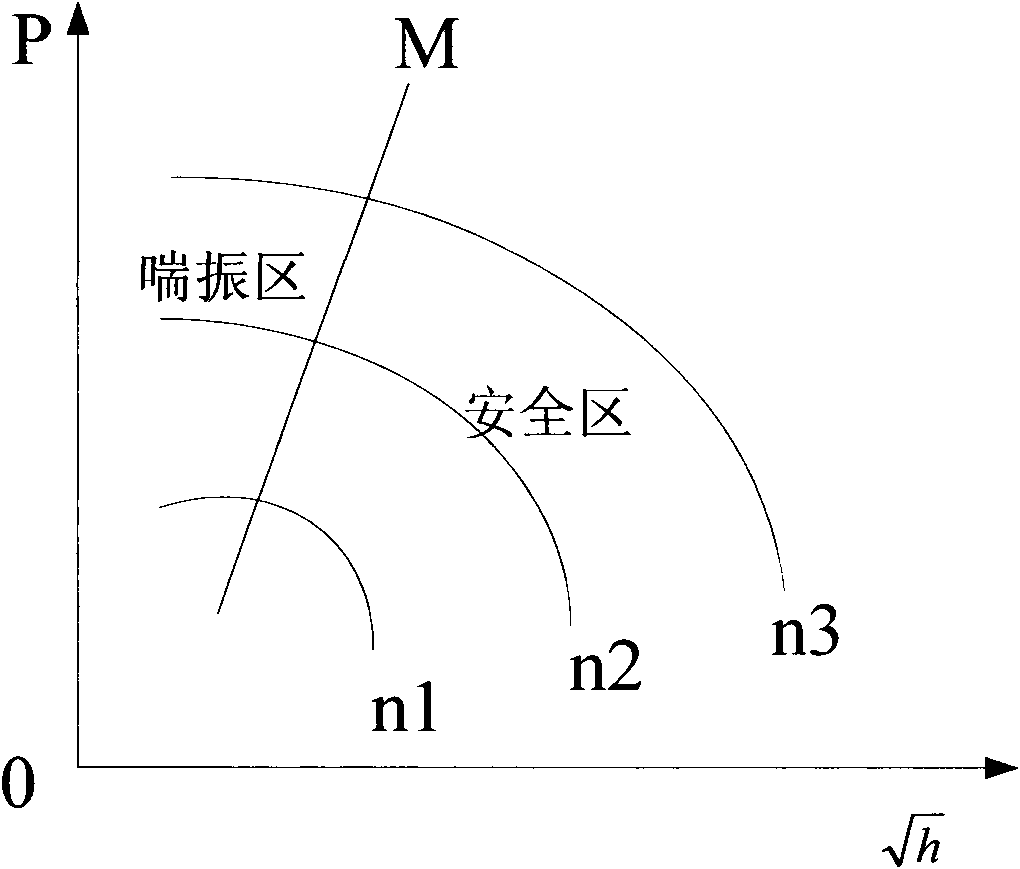

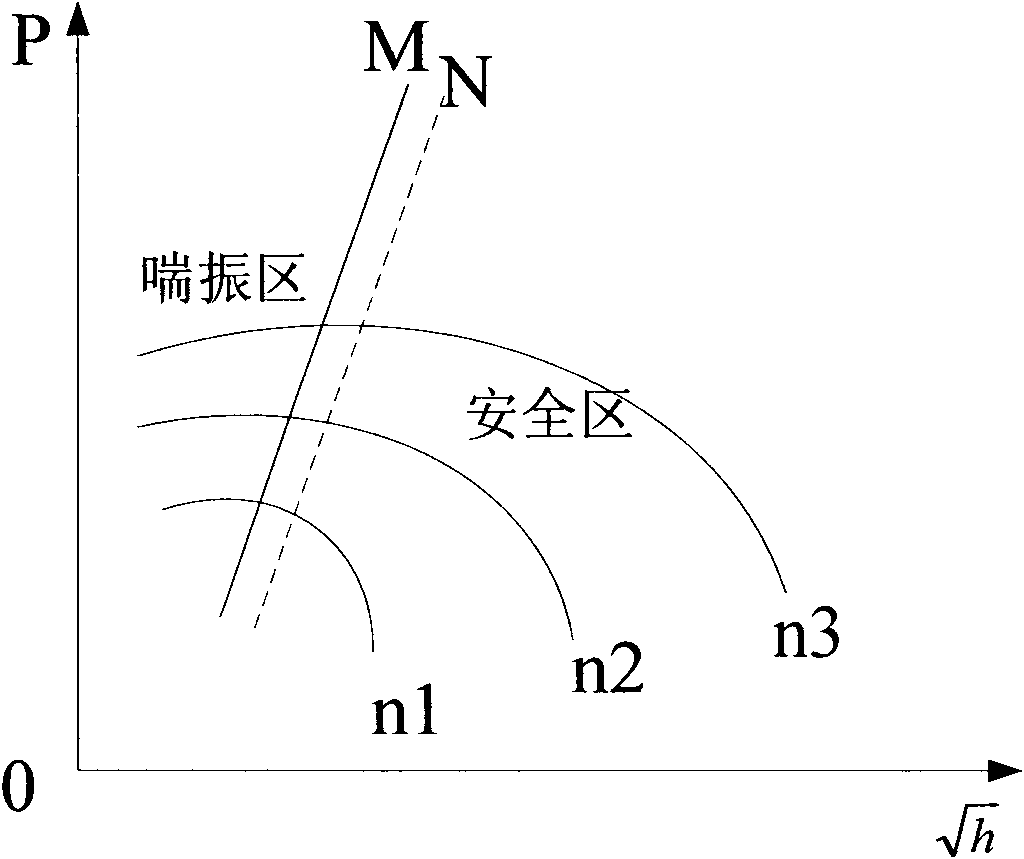

[0062] In order to clearly and fully introduce the technical solution of the present invention, some knowledge about surge is introduced below:

[0063] Surge refers to the mechanical vibration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com