Inclined type pressure regulating valve, manufacturing method and application method

A pressure regulating valve and tilting technology, which is applied in the field of pressure regulating valves, can solve problems affecting the popularization and use of agricultural water-saving irrigation technology, affecting the life of the pipeline at the water outlet, and affecting the popularization and use of the technology, so as to achieve a reasonable direction of force, Improved production efficiency and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

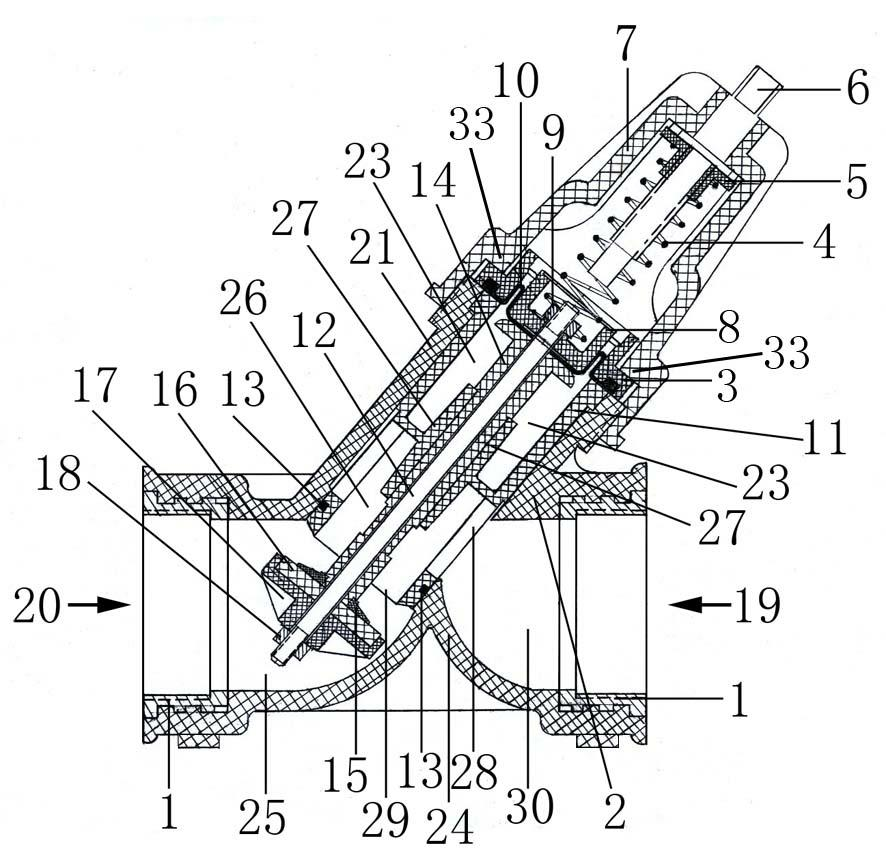

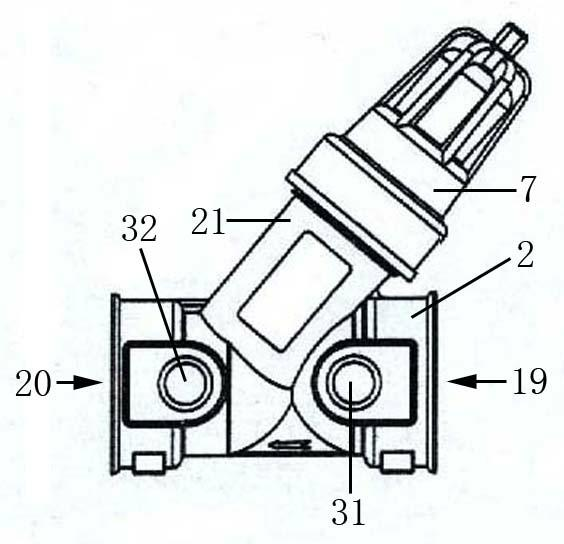

[0052] It is composed of valve body (2), valve core assembly (22) and valve cover (7). The valve body (2) is a three-way body, and the two ends of the valve body (2) are water inlet (19) and water outlet ( 20), the inner wall of the port of the water inlet (19) and the inner wall of the port of the water outlet (20) are respectively provided with metal threaded sleeves (1) to strengthen the connection strength of the thread, and the outer wall of the water inlet valve chamber (30) and the water outlet valve chamber The outer wall of (25) is provided with reserved positions for water inlet pressure gauge (31) and water outlet pressure gauge (32). According to design requirements, pressure gauges are installed to measure the pressure of water inlet and outlet in valve body (2). Regulate the pressure of the water outlet in the valve body (2).

[0053] The upper part of the valve body (2) is provided with a valve body upper port (21), the valve body upper port (21) is inclined to ...

Embodiment 2

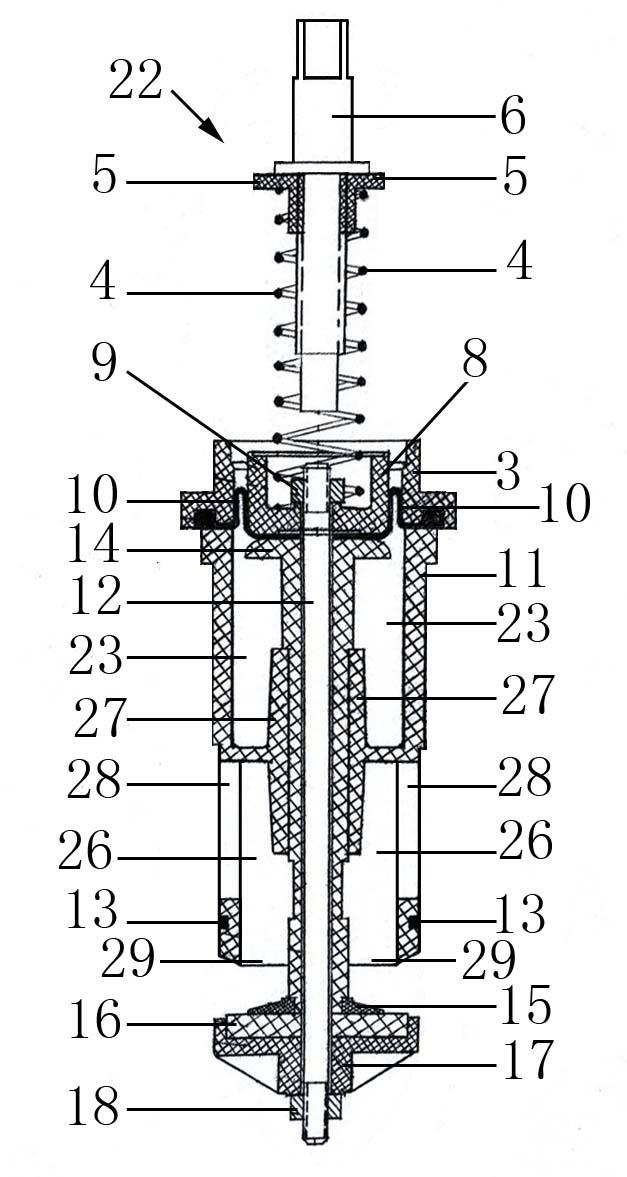

[0055]The spool assembly (22) consists of a sealing pressure ring (3), a pressure spring (4), an adjustment gland (5), a pressure adjustment drive rod (6), a spring seat buckle bowl (8), a positioning nut (9), Fine-tuning telescopic sealing bowl (10), valve core main body (11), valve core connecting screw (12), sealing rubber ring (13), support rod (14), gasket (15), sealing gasket (16), valve top (17) and lock nut (18), the spool connecting screw (12) runs through the spring seat buckle bowl (8), the fine-tuning telescopic sealing bowl (10), the support rod (14), the spool main body (11) from the center ), liner (15), gasket (16) and valve top (17), the two ends of the spool connecting screw (12) are locked with positioning nuts (9) and lock nuts (18).

[0056] The main body of the spool (11) is cylindrical as a whole, the upper part of the main body of the spool (11) is the pressure regulating chamber (23), the pressure regulating chamber (23) is a cylindrical blind hole, an...

Embodiment 3

[0066] The bonnet (7) is in the shape of a truncated cone as a whole, and a hollow hole is set on the top of the bonnet (7). The top end of the bonnet (7) passes through the hollow hole at the top of the bonnet (7), and the inner wall of the lower part of the bonnet (7) is provided with internal threads, and the internal threads of the bonnet (7) match the external threads of the upper port (21) of the valve body. The adjusting drive rod (6), adjusting gland (2) and pressure spring (4) are placed inside the bonnet (7), the bonnet (7) is fastened on the valve body upper port (21) The upper part of the internal thread is provided with a pressure platform (33) along the inner wall, and the bonnet (7) is tightened on the upper port (21) of the valve body, and the pressure platform (33) of the valve cover (7) presses the sealing pressure ring (3), Rotate and adjust the drive rod (6) from the outside of the valve cover (7) to adjust the pressure exerted by the pressure spring (4) on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com