Airtight testing device of steel pipe

An air tightness test, steel pipe technology, which is applied in the use of liquid/vacuum degree for liquid tightness measurement, by detecting the appearance of fluid at the leak point, etc. and other problems, to achieve the effect of high degree of automation, reduced labor intensity, and compact device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below with reference to the accompanying drawings.

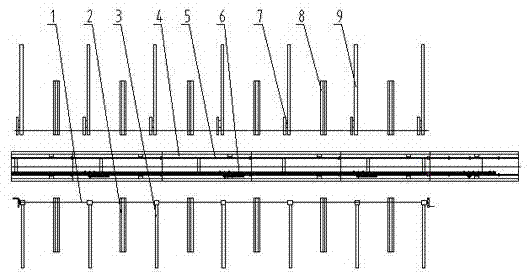

[0032] The water tank 4 of this device is a stainless steel water tank, and its length is determined according to the longest steel pipe length to be tested. A steel pipe is installed in the water tank to undertake the lifting platform 5, and a steel pipe input platform 1 and an input transmission mechanism 2, a steel pipe output platform 7 and an output transmission mechanism 8 are installed on both sides of the water tank.

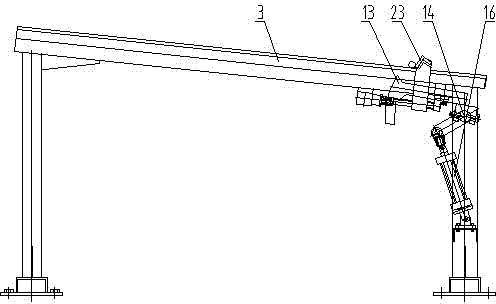

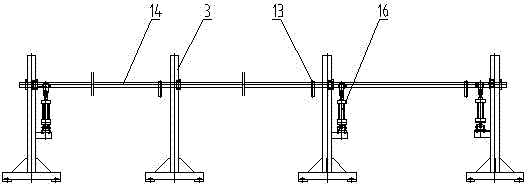

[0033] And the steel pipe accepts the elevating platform 5 by being installed in two fixed bearings 32, upper movable bearing 30 at the bottom of the water tank 4, the steel pipe positioning lath 28 installed on the upper movable bearing 30 by the support 29 and being connected to the fixed bearing. A number of movable connecting rods 31 between the seat 32 and the upper movable support 30 are formed, and the movable connecting rods 31 are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com