Electromagnetic band gap structure, electromagnetic band gap high-impedance substrate and planar travelling wave tube

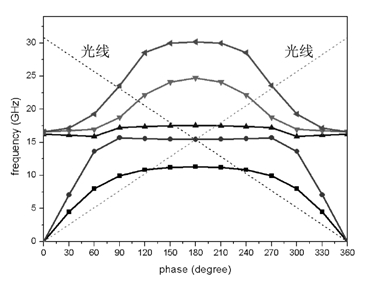

An electromagnetic bandgap structure and electromagnetic bandgap technology, applied in the field of physical electronics, can solve the problems of increasing the lateral size of the substrate, increasing the substrate area, unfavorable for manufacturing miniaturized equipment, etc., and achieving increased working bandwidth, simple process, and optimization. Effects of Dispersion Characteristics and Coupling Impedance Characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

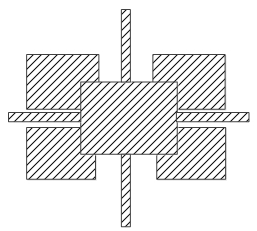

[0026] In the electromagnetic bandgap structure of the present invention, there is no specific requirement on the shapes of the two groups of closed metal curves, as long as the shapes of the two groups are different. The electromagnetic bandgap structure formed by two sets of metal closed curves, which are square and circular, respectively, will be described below as an example. This structure is simpler to manufacture.

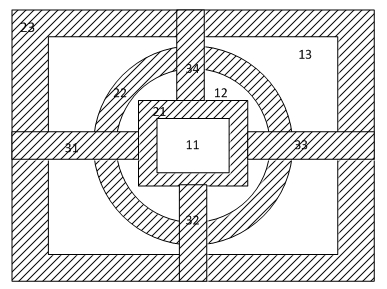

[0027] Such as image 3 As shown, the electromagnetic bandgap structure in this embodiment includes two groups of metal closed curves of different shapes, wherein one group is square 21, 23, 21 and 23 have the same shape and different size; the other group is circular 22 Two groups of metal closed curves are overlapped and surrounded sequentially from inside to outside; metal closed curves 21, 22, 23 are connected to each other by me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com