Preparation method of dendrobe health-care Pu'er tea cream

A technology for Pu'er tea paste and Pu'er cooked tea, which is applied in the field of preparation of Dendrobium health-care Pu'er tea paste, can solve problems such as being limited to 3 years, single, and has not yet been involved in the application of medicinal plants, so as to overcome the monotony of taste and guarantee The effect of simplicity, mellow taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

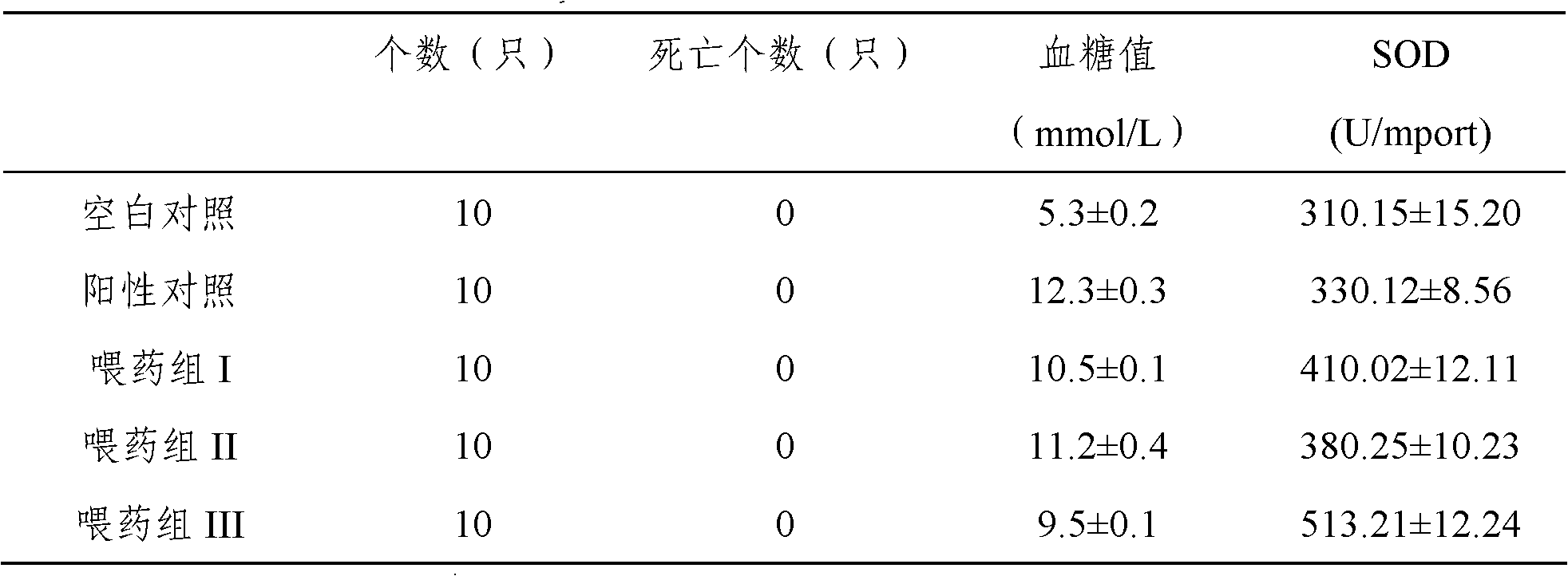

Embodiment 1

[0027] (1) Pu'er cooked tea extract:

[0028] ①Weigh 0.5kg of 1-year Pu-erh ripe tea, 1kg of 5-year-old Pu-erh ripe tea, 1.5kg of 10-year-old Pu-erh ripe tea and 2kg of 20-year-old Pu-erh ripe tea, and mix them into 5kg of Pu-erh tea raw materials;

[0029] ②Rinse the tea raw material with 20kg of pure water;

[0030] ③Dry the washed tea raw materials at a low temperature of 40±5°C until they can be crushed by hand, and then pulverized into fine powder with a crushing mill;

[0031] ④Put the powder sample into 50kg of pure water, reflux and leach for 15 minutes at a constant temperature of 45°C, let stand at room temperature and then filter to obtain filtrate I; add the filter residue to 50kg of pure water, boil and reflux for 10 minutes Minutes, left to stand to room temperature and suction filtered to obtain filtrate II, combined filtrates I and II to obtain Pu'er cooked tea extract;

[0032] ⑤Concentrate the Pu'er ripe tea extract to 1 / 4 of the original volume at a vacuum...

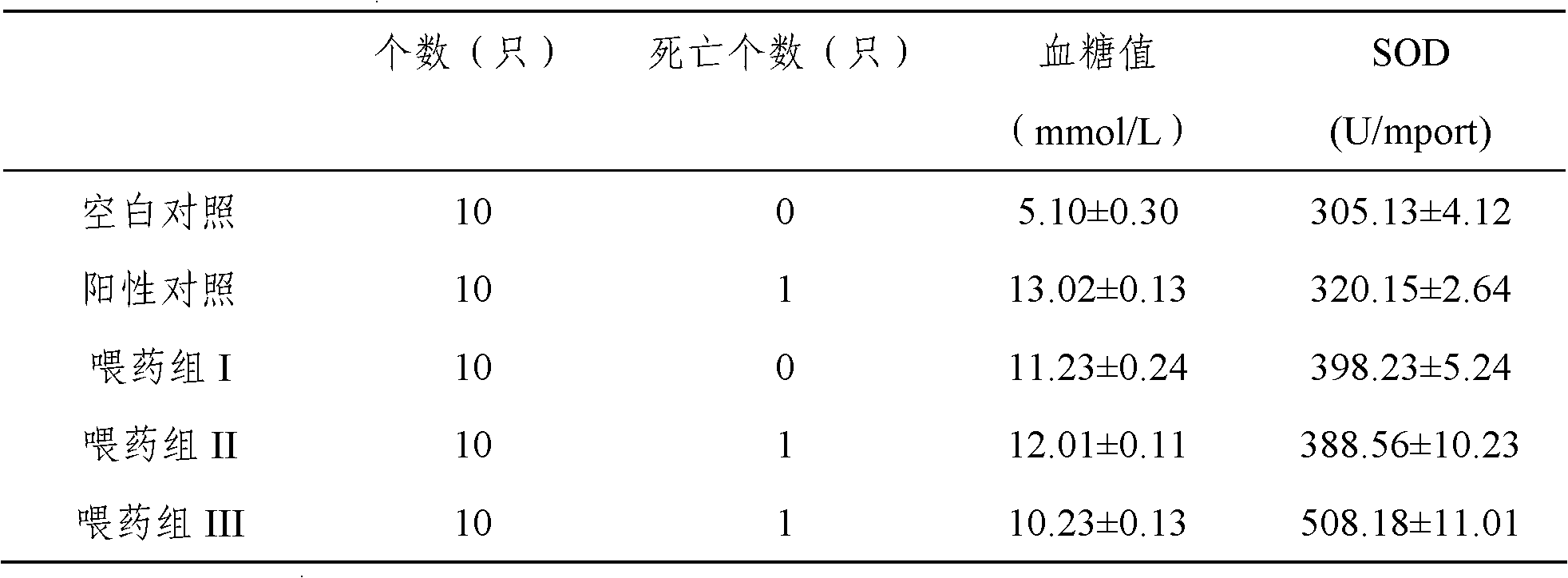

Embodiment 2

[0045] (1) Pu'er cooked tea extract:

[0046] ①Weigh 0.5kg of 1-year Pu-erh ripe tea, 1kg of 5-year-old Pu-erh ripe tea, 1.5kg of 10-year-old Pu-erh ripe tea and 2kg of 20-year-old Pu-erh ripe tea, and mix them into 5kg of Pu-erh tea raw materials;

[0047] ②Rinse the tea raw material with 25kg of pure water;

[0048] ③Dry the washed tea raw materials at a low temperature of 40±5°C until they can be crushed by hand, and then pulverized into fine powder with a crushing mill;

[0049] ④Put the powder sample into 45kg of pure water, reflux and leach for 15 minutes at a constant temperature of 45°C, let stand at room temperature and then filter to obtain filtrate I; add the filter residue to 45kg of pure water, boil and reflux for 10 minutes Minutes, left to stand to room temperature and suction filtered to obtain filtrate II, combined filtrates I and II to obtain Pu'er cooked tea extract;

[0050] ⑤Concentrating the Pu'er cooked tea extract at a vacuum degree of -0.070±0.01Mpa ...

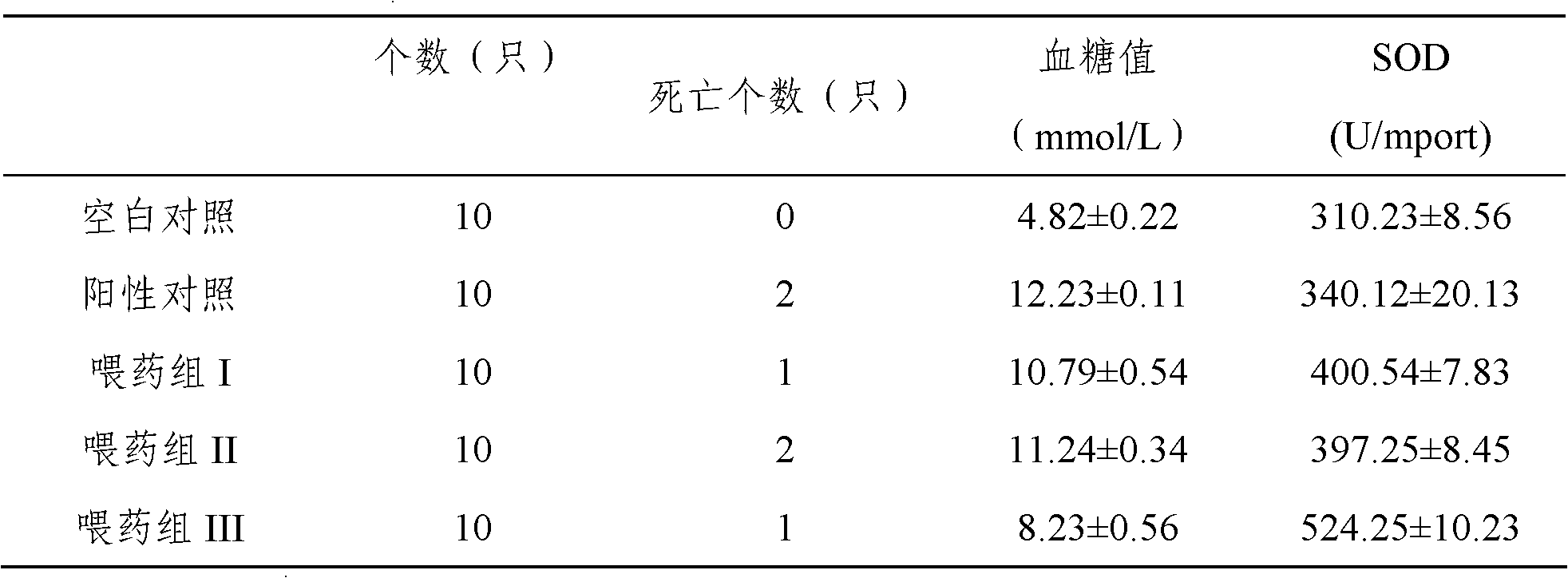

Embodiment 3

[0063] (1) Pu'er cooked tea extract:

[0064] ①Weigh 1kg of 1-year-old Pu-erh ripe tea, 1kg of 5-year-old Pu-erh ripe tea, 1.5kg of 10-year-old Pu-erh ripe tea, and 1.5kg of 20-year-old Pu-erh ripe tea, and mix them into 5kg of Pu-erh tea raw materials;

[0065] ②Rinse the tea raw material with 20kg of pure water;

[0066] ③Dry the washed tea raw materials at a low temperature of 40±5°C until they can be crushed by hand, and then pulverized into fine powder with a crushing mill;

[0067] ④Put the powder sample into 65kg of pure water, reflux and leach for 15 minutes at a constant temperature of 45°C, let stand at room temperature, and then filter to obtain filtrate I; add the filter residue to 65kg of pure water, boil and reflux for 10 minutes Minutes, left to stand to room temperature and suction filtered to obtain filtrate II, combined filtrates I and II to obtain Pu'er cooked tea extract;

[0068] ⑤ concentrating the Pu'er cooked tea extract to 1 / 4 of the original volume ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com