Handmade cushion and production technology thereof

A production process and technology of cushions, applied in the field of cushions, can solve the problems of not being high-end, luxurious and beautiful, wet, poor heat dissipation, etc., and achieve high-quality life enjoyment, enrich daily necessities, and facilitate ventilation and ventilation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

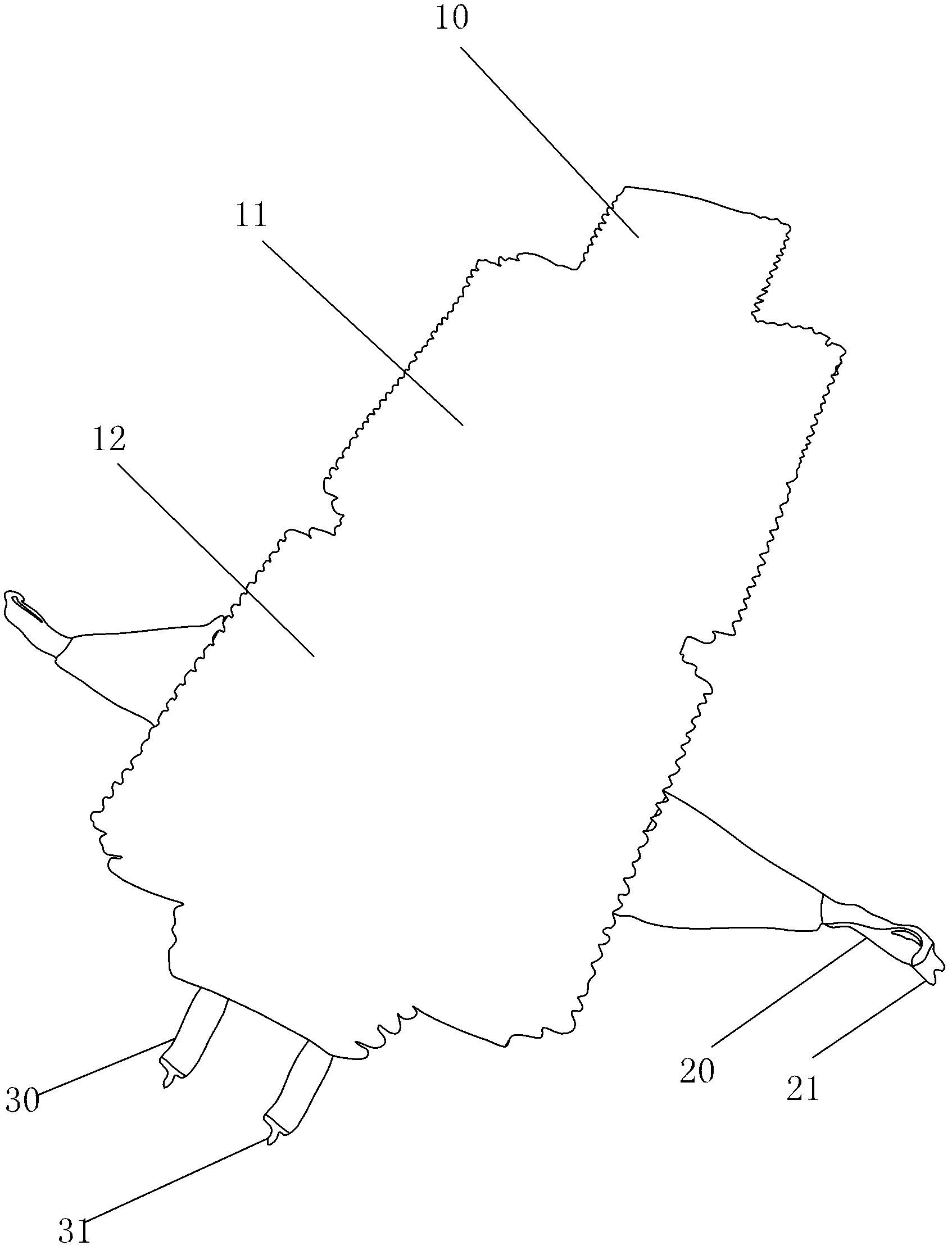

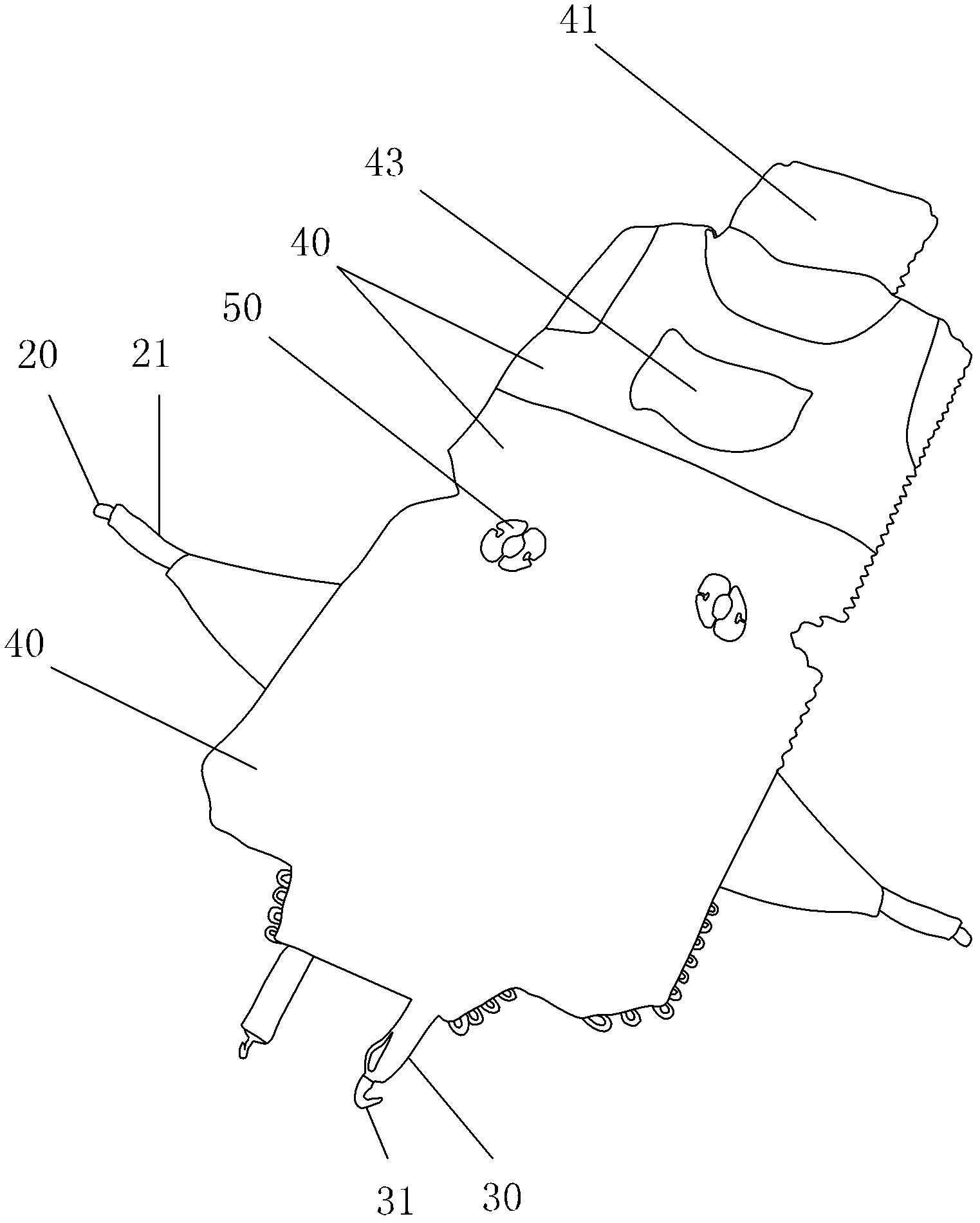

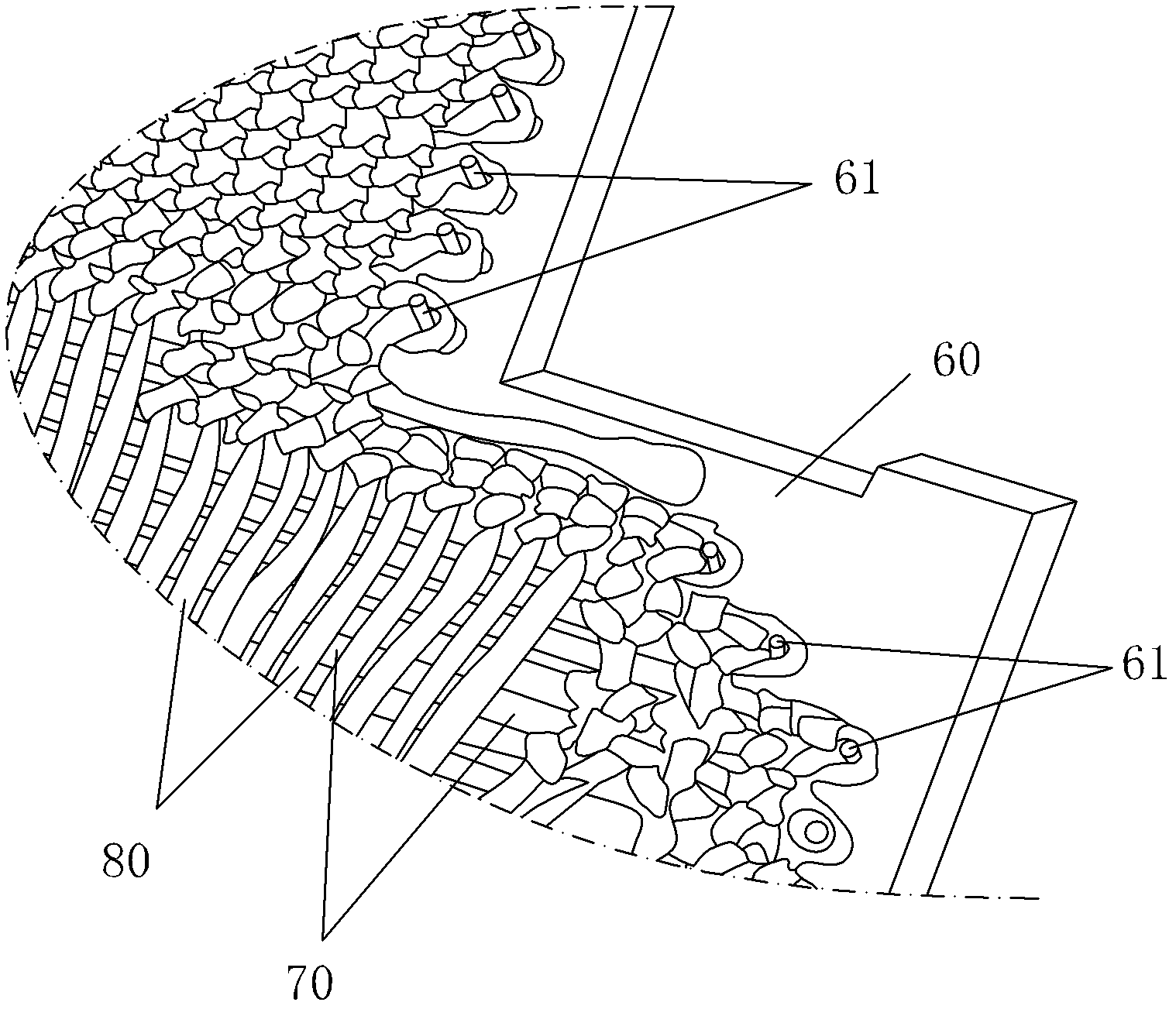

[0029] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1-3 :

[0030] A production process of a handmade cushion is completed according to the following steps:

[0031] (1) Material selection: choose leather or cotton cloth or chemical fiber cloth as the raw material for production;

[0032] (2) Processing of material selection: dipping or applying glue, drying and high-temperature sterilization on the selected raw materials;

[0033] (3) Stripping: cutting the raw material made in step (2) into strip sheets with a width of 0.3-3cm;

[0034] (4) making strips: the both sides of the front width direction of described strip sheet material are folded into the required width to the reverse side, and the folded edges are sewed to form a strip 80 with a certain width for weaving;

[0035] (5) Make the inner rib 70 on the cushion frame 60: set the warp or weft thread suspension column 61 on the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com