Three-level refining method and system for disinfectant steam

A three-level refinement and disinfectant technology, applied in the direction of gasification substances, chemistry, etc., can solve the problems of large atomized gas droplets, decomposition of disinfectants, excessive temperature difference in disinfection environment, etc., to achieve improved atomization efficiency, The effect of improving the disinfection effect and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

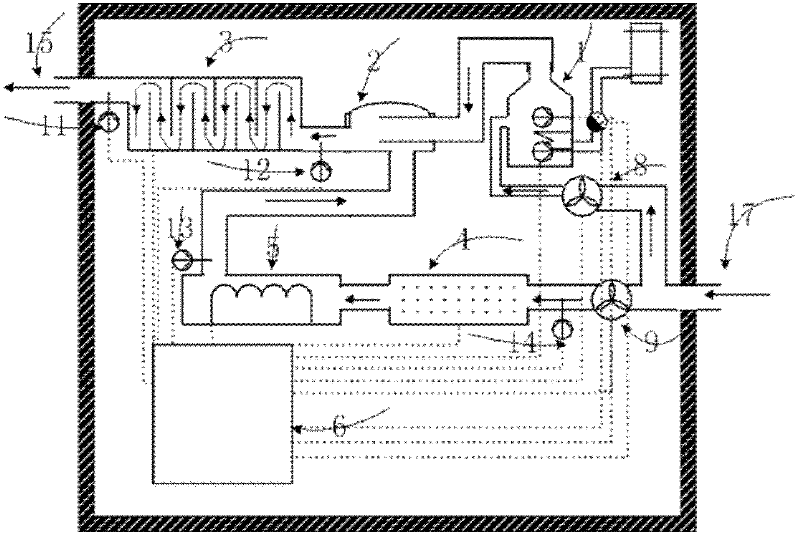

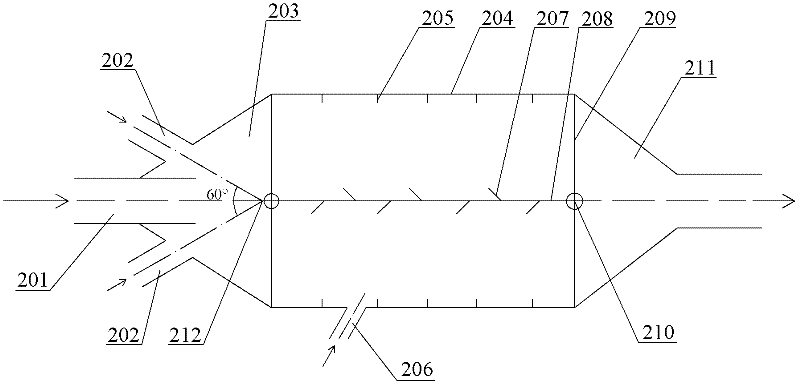

[0032] A three-stage refinement method for disinfectant vapor of the present invention, first, utilizes ultrasonic atomization technology to carry out primary atomization on disinfectant liquid; secondly, utilizes mixing refinement technology to impact hot air and disperse disinfectant atomized gas, Use the airflow to collide, cut, and break the atomized gas, effectively break the disinfectant atomized gas molecular clusters, and refine the disinfectant atomized gas twice; finally, use the evaporation technology to mix the disinfectant and air with the inner wall of the evaporator Full contact, heating and evaporation make the atomized gas three times thinner, so as to achieve the purpose of outputting disinfectant vapor of ultrafine particles.

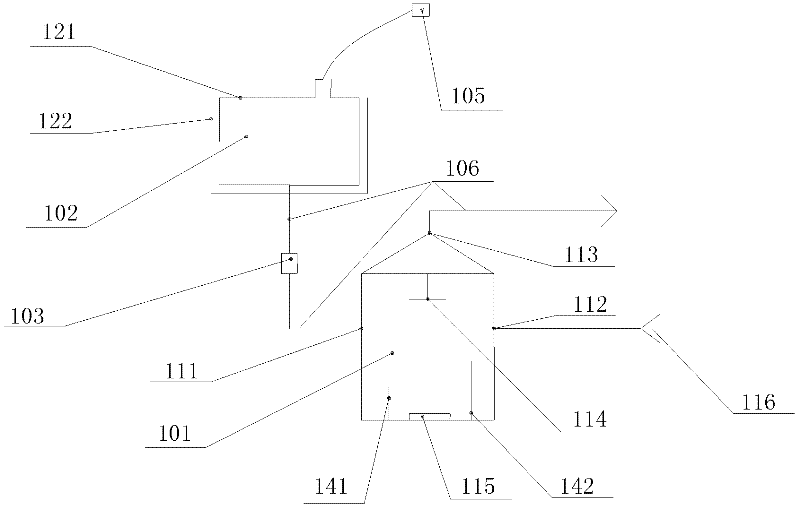

[0033] Such as figure 1 As shown, the disinfectant vapor three-stage refining system for realizing the above method includes: an ultrasonic atomization device 1, a mixing and refining device, an evaporator 3 and a control system. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com