Coated glass, and preparation method and equipment thereof

A technology of coated glass and glass substrate, which is applied in the direction of chemical instruments and methods, glass/slag layered products, layered products, etc., can solve the problems of polyvinyl alcohol hot melting difficulties, etc., and achieve strong film adhesion and water washing Ease of film formation and fast curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

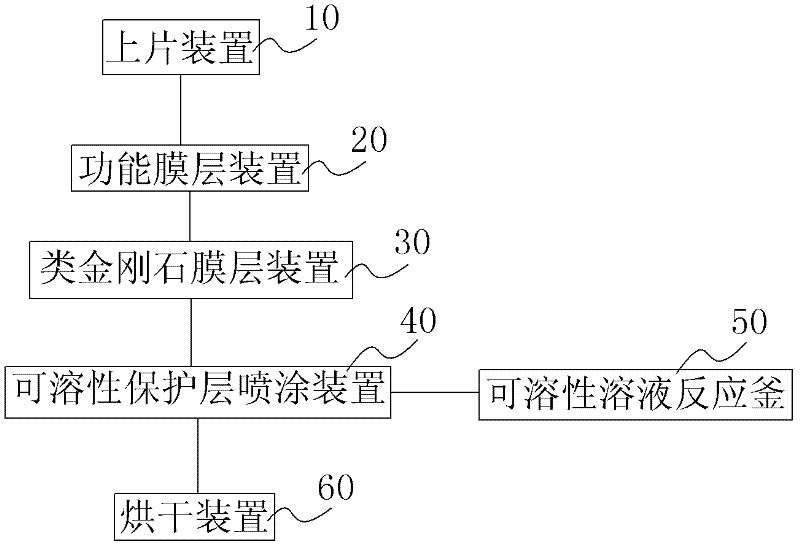

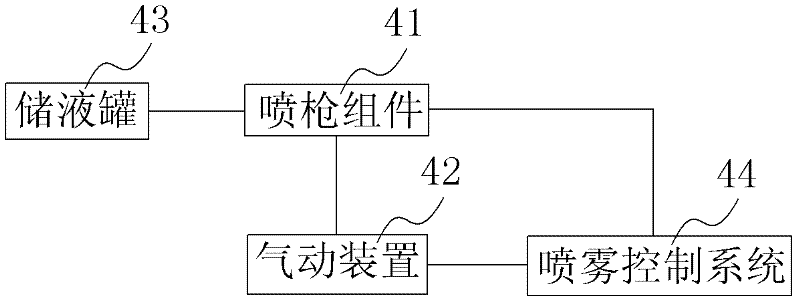

[0052] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

[0053]The soluble protective film and its preparation method disclosed in the present invention, as a film surface protection method for Low-E glass, replaces the protection methods such as Low-E glass PE film, thereby reducing costs, improving production efficiency and product quality, and facilitating industrialization. No pollution to the environment.

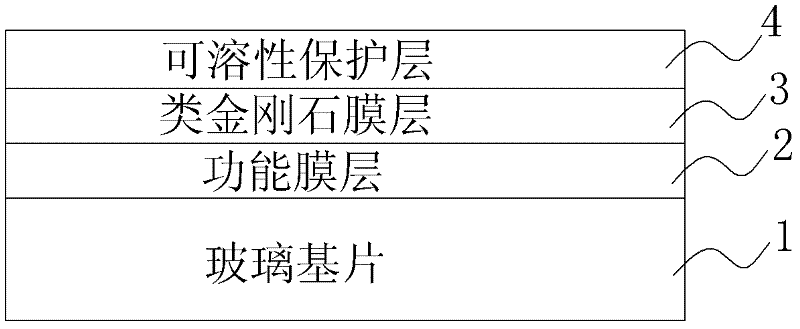

[0054] see figure 1 , figure 1 It is a schematic structural diagram of a coated glass according to an embodiment of the present invention. The coated glass of the present invention includes a glass substrate 1 and a functional film layer 2 and a diamond-like film layer 3 attached to the glass substrate 1 in sequence, and also includes a soluble protective layer 4 attached to the soluble protective layer 4. The diamond-like carbon film layer 3 outside. The soluble protect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| esterification rate | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com