Blockage bridging removal machine for ore bin

A technology of mine silo and shed material, applied in the field of blocking shed material clearing machine, can solve the problems of high operating cost, complex structure and high cost, and achieve the effects of strong market competitiveness, simple structure, and convenient processing, installation and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further describe the present invention, the blockage clearing machine of the present invention will be further described in conjunction with the accompanying drawings and embodiments.

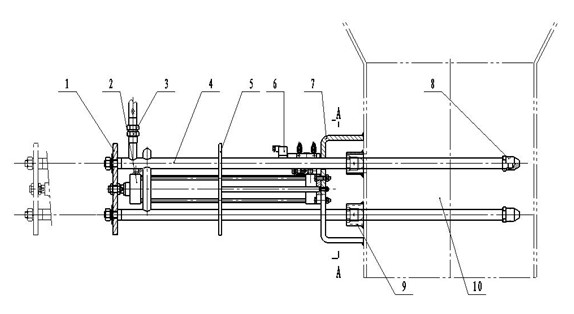

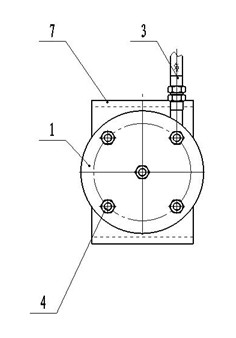

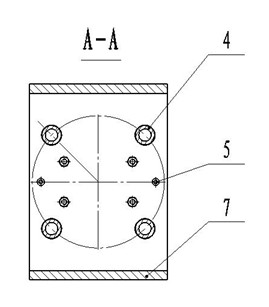

[0021] Depend on figure 1 The main body of the blockage clearing machine of the mine block shed material shown in the present invention is a schematic structural diagram of the top view and combined with figure 2 , image 3 Find out that the present invention is composed of the electromagnetic reversing valve 6 combination of pressurized plate 1, cylinder 2, compressed air inlet pipe 3, smashing device 4, support 7, control cylinder reciprocating. On the piston rod head of the cylinder 2, a circular pressure plate 1 is set, and the pressure plate 1 is fixed to the piston rod head by a large nut. The pressure plate 1 can reciprocate with the piston rod. There are four round holes processed on the pressure plate 1, and the mashing device 4 fixes the mashing device on the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com