Two-vertical-column belt lifter capable of separating workpiece from rail to realize transshipment

A technology of lifts and columns, applied in the field of two-column belt lifts, can solve the problems of high processing and manufacturing costs, expensive telescopic forks, and increased production costs, and achieve the effects of easy on-site installation, easy maintenance and maintenance, and increased production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

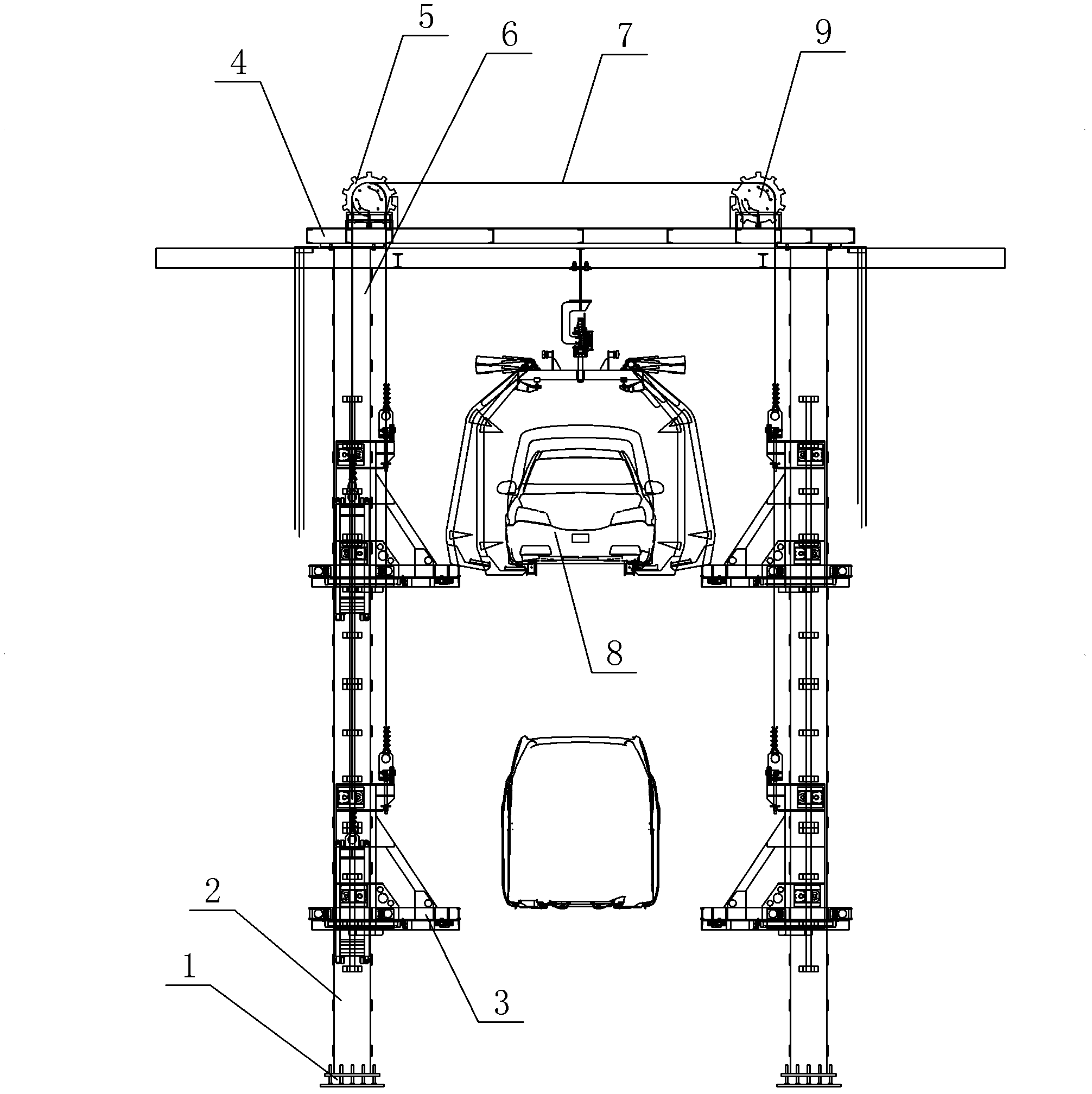

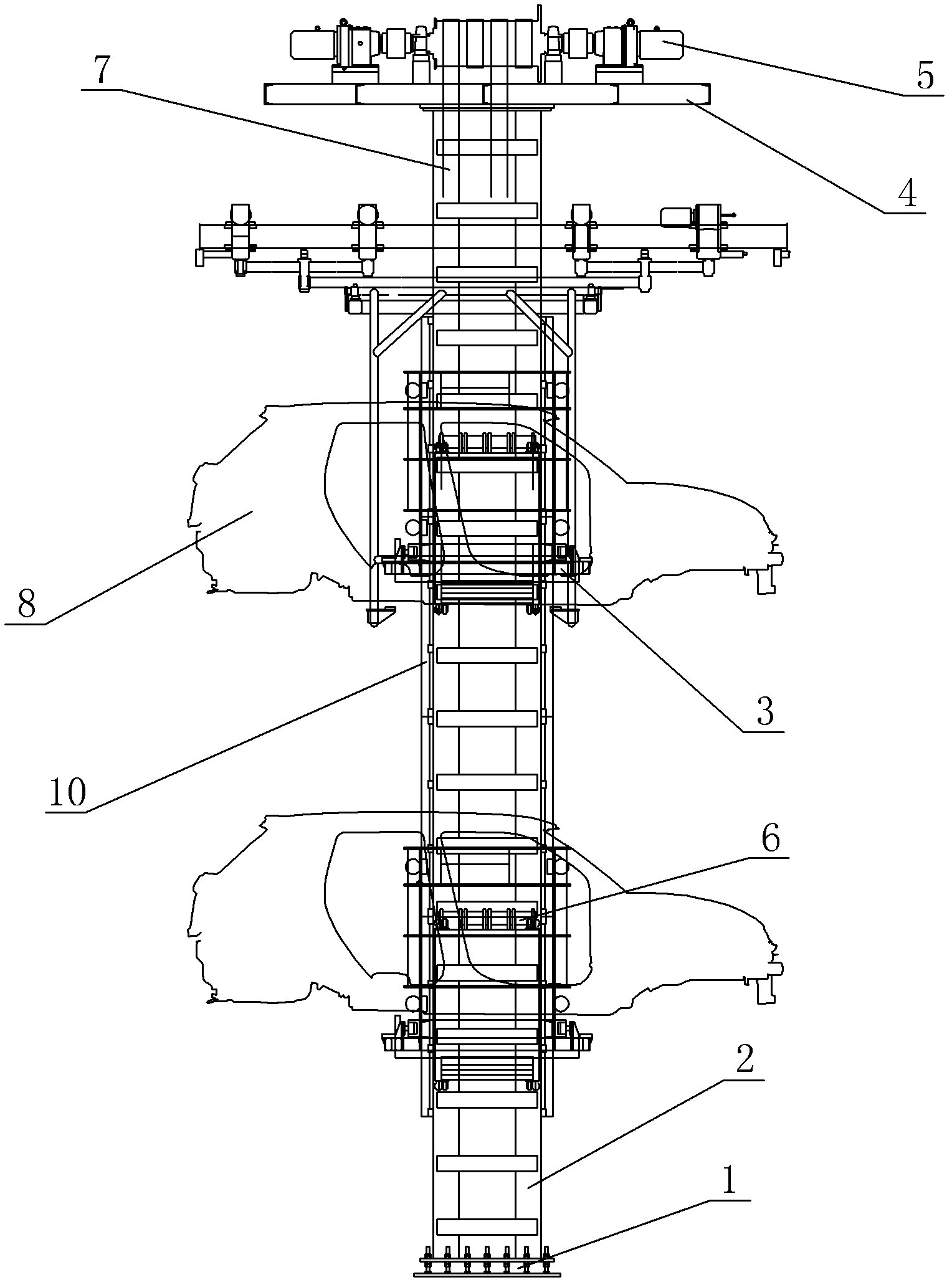

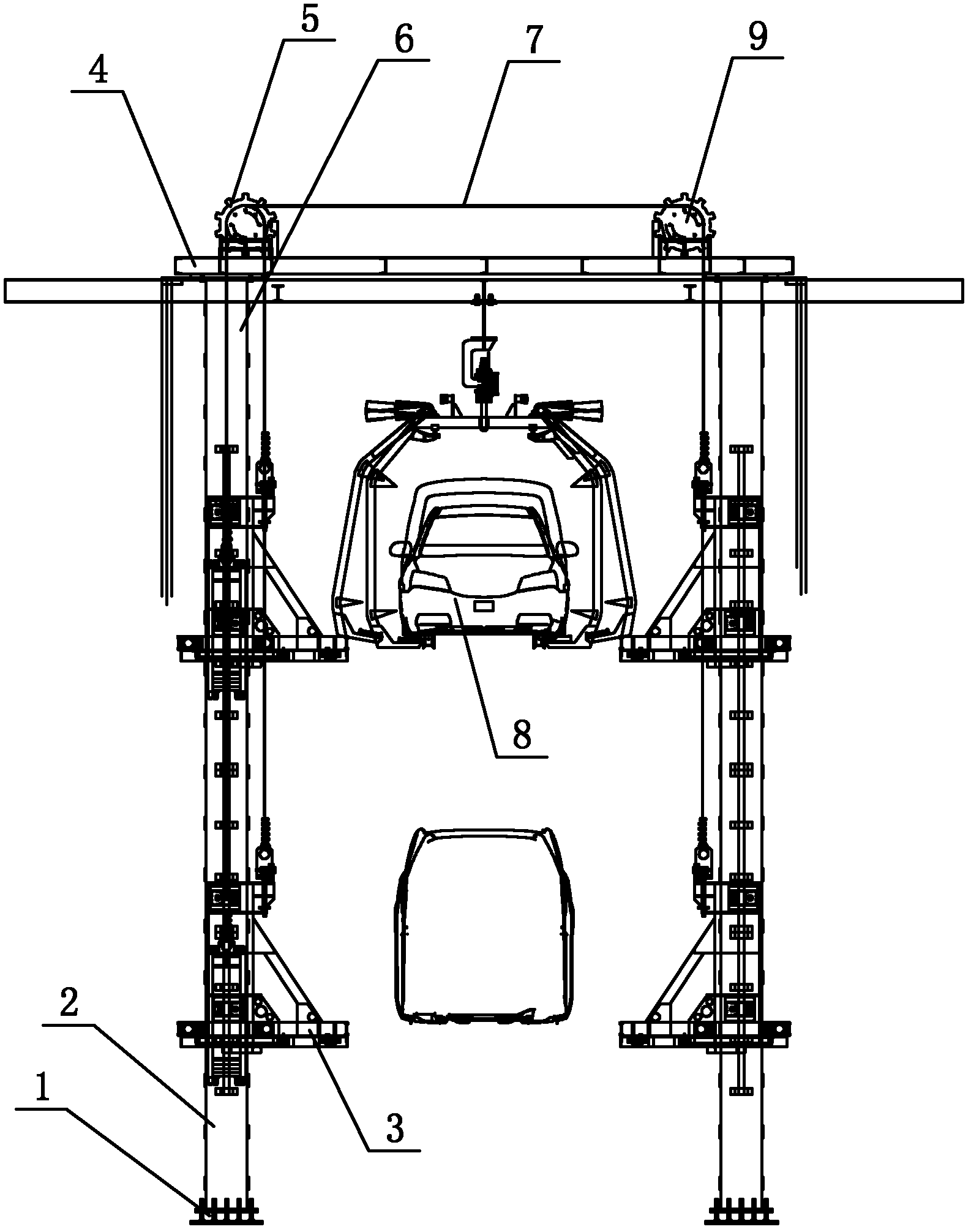

[0014] see figure 1 As shown, in this embodiment, a two-column belt lift that can be derailed and reproduced includes two uprights 2, and the uprights 2 are formed by bending parts facing each other and connecting ribs, and widening the width of the non-rail mounting surface of the uprights , the bottoms of which are all connected to the lift base 1, and the top of the column 2 is connected to the top frame 4 of the lift, the carriage 3 can slide up and down on the column 2, and the rail 10 is laid on the column 2, and the carriage 3 The guide wheel and the running wheel that can hold the track 10 are installed on the top, and the carriage 3 is limited by the guide wheel to hold the track 10 and walk on the track of the column 2. The driving roller assembly 5 and the redirection are installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com