Tailing sand two-component soil pavement sub-base layer mixture and preparation method thereof

A technology of tailings sand and subbase, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., to achieve the effect of reducing land, reducing the pressure on land resources, and increasing the difficulty of construction technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

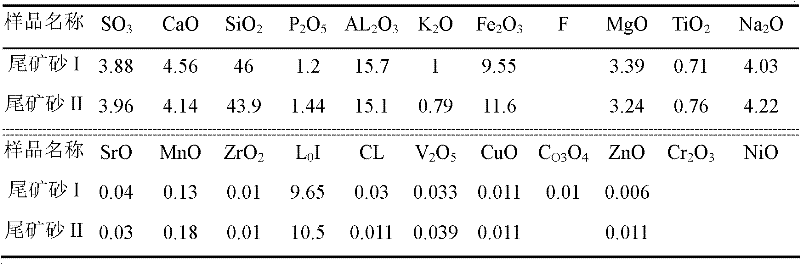

[0020] A representative tailings sand sample was taken from a two-iron beneficiation tailings pond in Jiangning District, Nanjing City, and X-ray diffraction test of mineral composition and sample particle size analysis test were carried out respectively, as shown in Table 1 and Table 2.

[0021] Table 1 Analysis and detection results of chemical composition of tailings sand

[0022]

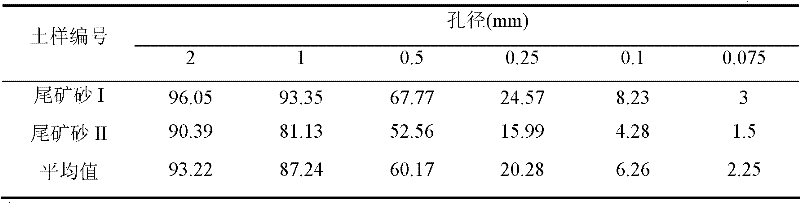

[0023] Table 2 tailings sand particle passing rate (%)

[0024]

[0025] From the perspective of material composition, the tailings sand is mainly composed of stable SiO 2 、Al 2 o 3 , Fe 2 o 3 Therefore, the tailings sand has good engineering stability and has engineering utilization value. At the same time, according to the individual characteristics of tailings sand particles, it can be judged that it is medium sand, and the distribution of particle groups is continuous, which meets the necessary conditions for road filling.

[0026] In this example, the physical and mechanical pro...

Embodiment 2

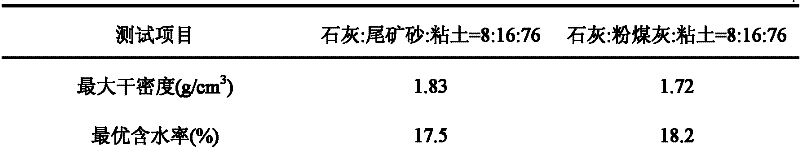

[0032] The used tailings sand chemical composition and particle group characteristics of the present embodiment are as described in Example 1, and are equally stable to tailings sand combined soil (iron beneficiation tailings sand-lime-cohesive soil) mixture subbase material and traditional lime fly ash respectively The physical and mechanical properties of soil subbase materials are tested and analyzed. The difference lies in the content of tailings sand, fly ash and cohesive soil in the two subbase materials. Among them: the weight percentage of each component of the tailings-sand mixed soil mixture is 24% of tailings sand, 8% of lime, and 68% of cohesive soil; the weight percentage of each component of lime fly ash stabilized soil is 8% of lime and 24% of fly ash , Clay soil 68%.

[0033] Table 4 shows the experimental performance test data of the two kinds of base layer materials in this embodiment.

[0034] Table 4 Experimental performance test data of two kinds of subba...

Embodiment 3

[0037] A kind of mixture of tailings sand and composite pavement subbase, which is composed of iron ore dressing tailings, lime, clay and water to form a mixture of two composite soil subbases. The weight percentages of iron ore dressing tailings, lime and clay are as follows:

[0038] Iron beneficiation tailings 15%~40%

[0039] Lime 5%~10%

[0040] Clay soil 50%~80%

[0041] The amount of water added is 5% to 20% of the total mass of iron beneficiation tailings sand, lime and clay,

[0042] In the present embodiment, the percentage by weight of iron dressing tailings sand, lime, clay can be: 15%: 5%: 80%, 40%: 10%: 50%, 30%: 10%: 60% or 20%: 8%: 72%; the addition of water is 5%, 20% or 10% of the total mass of iron beneficiation tailings, lime and clay,

[0043] Among the chemical components of the iron beneficiation tailings sand, the active component SiO 2 、Al 2 o 3 and Fe 2 o 3 The total content of the iron beneficiation tailings accounts for more than 70% of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com