Method for preparing dichloroethane through direct chlorination by using dry gas

A dichloroethane and dry gas technology, applied in the field of dichloroethane preparation, can solve the problems of reducing ethylene conversion rate, affecting product purity, and no discussion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

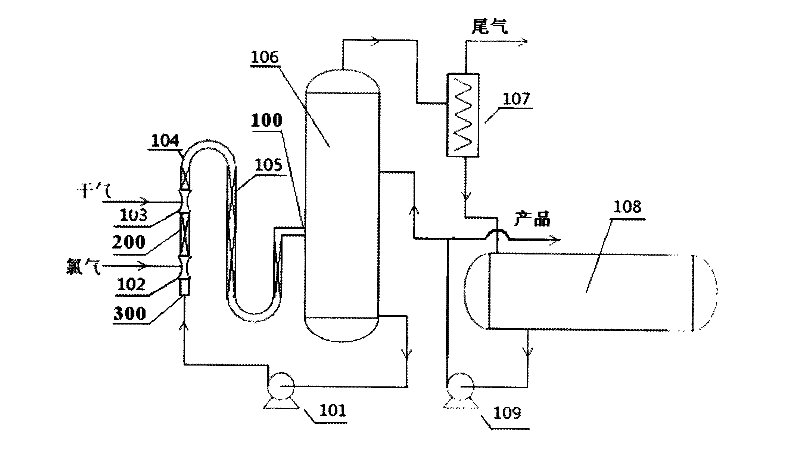

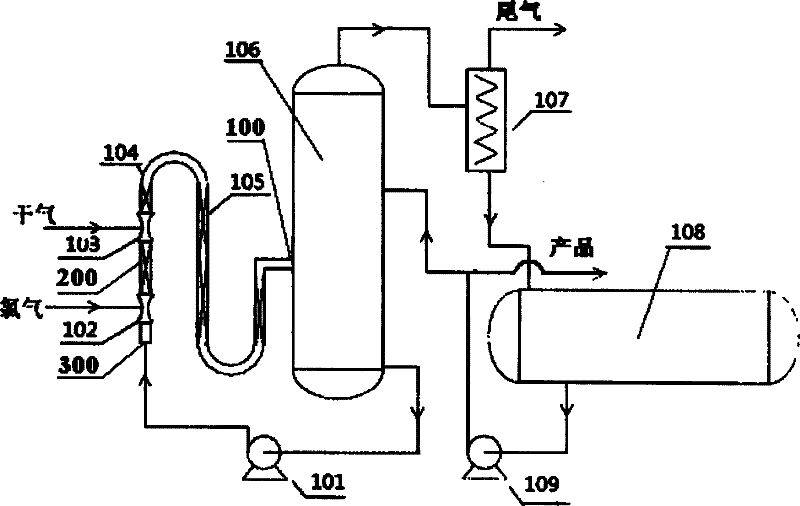

[0028] use figure 1 process. The internal components adopt SK type static mixer.

[0029] In the untreated refinery dry gas, the weight content of each component is shown in the table below.

[0030] List of Dry Gas Components

[0031] composition

H 2

O 2

N 2

CO

CH 4

C 2 h 6

C 2 h 4

C 3 h 8

C 3 h 6

C 4

C 5

h 2 S

content

19.75

0.63

20.9

1.63

26.52

3.14

17.72

0.48

4.67

4.05

0.51

1ppm

[0032] The weight ratio of each component is:

[0033] Dry gas: dichloroethane mother liquor = 1: 139;

[0034] Dry gas: chlorine = 1: 1.5;

[0035] The reaction temperature is 84°C;

[0036] Dwell time is 12 seconds;

[0037] By adopting the above-mentioned method, the weight concentration of dichloroethane obtained can reach 90.56%, the conversion rate can reach 96%, and the reaction selectivity of ethylene can reach 99%...

Embodiment 2

[0039] use figure 1 process.

[0040] The internal components adopt SK type static mixer.

[0041] The weight content of each component in the refinery dry gas after pressure swing adsorption is shown in the table below.

[0042] List of Dry Gas Components

[0043] composition

H 2

N 2

CH 4

C 2 h 4

C 2 h 6

total

Content w%

0.05

0.97

7.79

65.41

25.78

100

[0044] The weight ratio of each component is:

[0045] Dry gas: dichloroethane mother liquor = 1: 405;

[0046] Dry gas: chlorine = 1: 1.9;

[0047] The reaction temperature is 110°C;

[0048] Dwell time is 12 seconds;

[0049] By adopting the above-mentioned method, the weight concentration of the obtained dichloroethane can reach 97.66%, the conversion rate can reach 99%, and the ethylene reaction selectivity can reach 99%.

Embodiment 3

[0051] use figure 1 process.

[0052] The internal components adopt SK type static mixer.

[0053] The weight content of each component in the refinery dry gas after pressure swing adsorption is shown in the table below.

[0054] List of Dry Gas Components

[0055] composition

H 2

N 2

CH 4

C 2 h 4

C 2 h 6

total

Content w%

0.47

2.94

10.95

76.55

9.09

100

[0056] The weight ratio of each component is:

[0057] Dry gas: dichloroethane parent = 1: 363;

[0058] Dry gas: chlorine = 1: 2.7;

[0059] The reaction temperature is 84°C;

[0060] Dwell time is 18 seconds;

[0061] By adopting the above method, the weight concentration of dichloroethane obtained can reach 98.94%, the conversion rate can reach 98%, and the ethylene reaction selectivity can reach 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com