Ultraviolet (UV) cured plastic coating

A technology of plastic coatings and resins, applied in polyester coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor weather resistance of UV coatings, residues of photosensitizer fragments, and human toxicity, achieving fast curing speed and saving Energy, the effect of overcoming poor weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

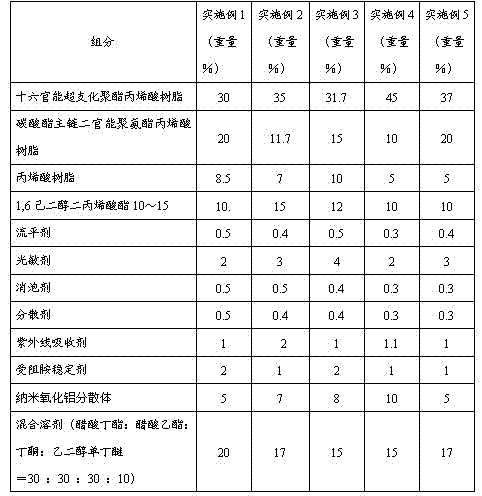

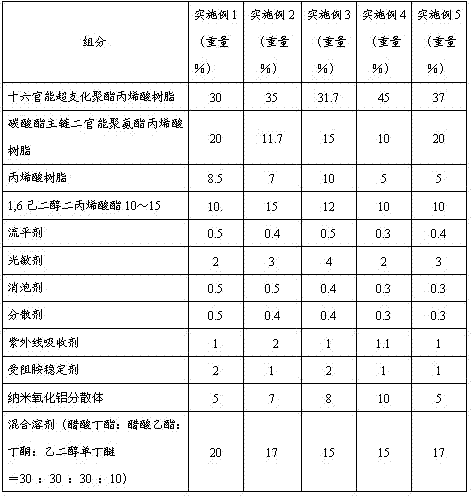

[0055] through such as figure 1 The illustrated Examples 1-5 illustrate the present invention in further detail.

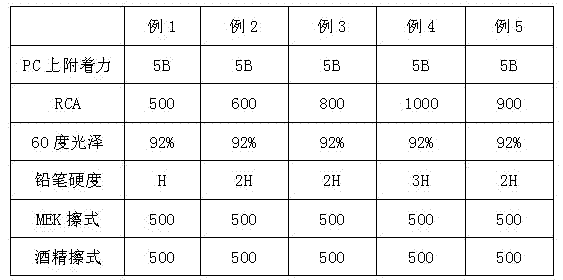

[0056] Will figure 1 The components in any proportion of Examples 1 to 5 are added to the container according to the stated ratio, mixed evenly under stirring conditions, sprayed on the PC plastic, baked at 60°C for 3 minutes, and then irradiated with 600mj / cm2 UV light The curing machine is used for curing to obtain the coating. Then the performance test of the coating, the results are as follows: figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com