Anisotropic conductive film

An anisotropic, conductive film technology, applied in conductive adhesives, conductive materials dispersed in non-conductive inorganic materials, modified epoxy resin adhesives, etc., can solve problems such as deterioration of basic electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

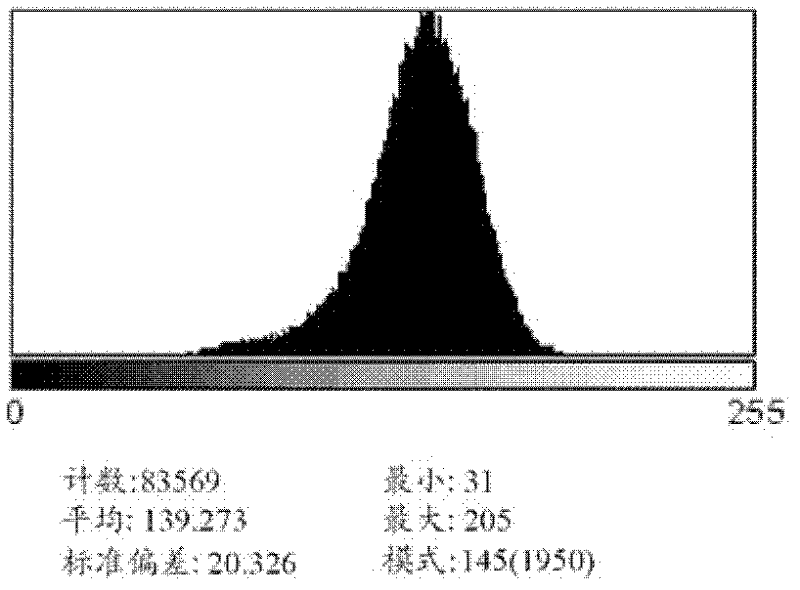

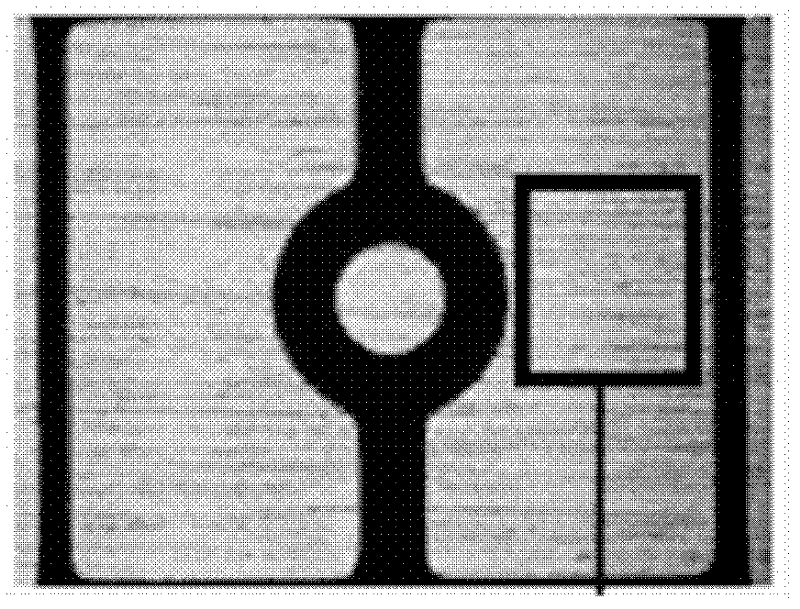

Image

Examples

Embodiment 1

[0071] Example 1: Preparation of anisotropic conductive film

[0072] 30g solution (25vol%) of acrylonitrile butadiene rubber (weight average molecular weight=30000000g / mol) in toluene / methyl ethyl ketone (2:1 (v / v)), 15g bisphenol A type epoxy Resin, 33g of bisphenol A type epoxy acrylate resin, 5g of phosphoethyl (meth)acrylate, 1g of lauroyl peroxide, 1g of benzoyl peroxide, 8g of nickel with an average particle size (D50) of 5 μm The particles were blended with 1 g of copper-chromium oxide (Black 30C965, Shepherd) to prepare an anisotropic conductive film composition. This composition was coated on a polyethylene terephthalate film as a release film, and dried to prepare an anisotropic conductive film having a coating thickness of 35 μm.

Embodiment 2~7

[0073] Examples 2-7: Production of anisotropic conductive film

[0074] An anisotropic conductive film was produced in the same manner as in Example 1, except that the content and / or type of each component was changed as shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com