Preparation technology for fine-grained steel 510L

A preparation process and technology of fine-grained steel, applied in the direction of manufacturing converters, etc., can solve the problems of high sulfide content, difficulty in grain size level above 10, and lack of controlled rolling and cooling system for rolled steel, so as to improve product quality. The effect of grain size level, improved cold workability, and improved product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

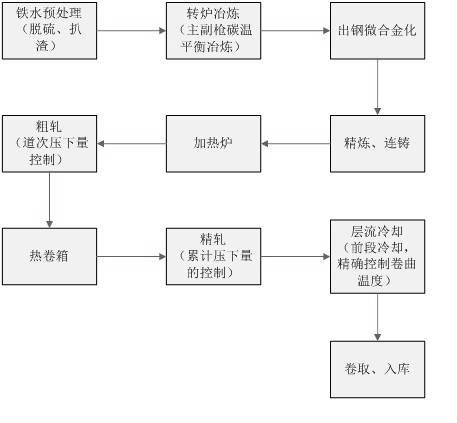

[0011] Process flow of the present invention is:

[0012] a. Pretreatment process, using the method of spraying passivated magnesium into molten iron to remove sulfur, controlling the amount of magnesium injection, injection pressure, and injection flow rate, and prolonging the contact time between magnesium and molten iron;

[0013] b. Converter steelmaking: adopt sub-gun steelmaking technology, add medium carbon ferromanganese, ferrosilicon and ferroaluminum for deoxidation alloying after tapping, control the oxygen of molten steel after deoxidation alloying, add Nb iron at the end of tapping to determine the composition of molten steel Nb Micro-alloying, the steel ladle is supplemented by bottom blowing argon stirring while tapping;

[0014] c. After micro-alloying by converter tapping, after refining treatment, fine-tuning of molten steel composition temperature is carried out by adding alloy and feeding aluminum wire by wire feeding machine. At the same time, soft argon b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com