A kind of high-iron cupronickel alloy pipe material and its short-process production method

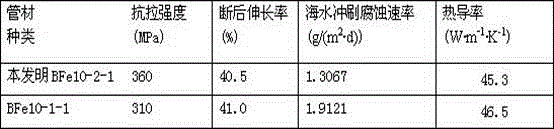

A production method and technology for white copper pipes, applied in the field of metal materials, can solve the problems of poor processing performance and low yield of iron white copper, and achieve the effects of excellent cold processing performance, improved cold processing performance, and good internal and external surface quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: The size is Φ60×3mm BFe10-2-1 white copper alloy straight tube production method

[0023] (1) Electrolytic nickel with a weight percentage of 10.0wt%, pure iron with a weight percentage of 2.0wt%, and 100% by weight

[0024] Add pure manganese with a ratio of 1.0wt% and the balance of electrolytic copper into the melting furnace, heat to 1250°C for melting, transfer the molten metal into the holding furnace, and let it stand for 0.5h at the temperature of the holding furnace at 1200°C , At the same time, the inert gas protection is passed through the holding furnace.

[0025] (2) A high-iron white copper tube billet with a diameter of Φ85×10mm was prepared by the horizontal continuous casting process of the hot-cold combined mold,

[0026] The temperature of the hot type (mold heating section) is 1220°C, the cooling water flow rate of the cold type (water-cooled copper sleeve) is 900L / h, and the pulling speed is 120mm / min.

[0027] (3) The tube blank pre...

Embodiment 2

[0033] Example 2: The production method of BFe10-2-1 white copper straight tube with a size of Φ40×2mm

[0034](1) Electrolytic nickel with a weight percentage of 10.0wt%, pure iron with a weight percentage of 1.8wt%, and 100% by weight

[0035] Add pure manganese with a ratio of 1.0wt% and the balance of electrolytic copper into the melting furnace, heat to 1250°C for melting, transfer the molten metal into the holding furnace, and let it stand for 0.5h at the temperature of the holding furnace at 1200°C , At the same time, the inert gas protection is passed through the holding furnace.

[0036] (2) A high-iron white copper tube billet with a diameter of Φ70×8mm was prepared by using a hot-cold combined mold horizontal continuous casting process,

[0037] The temperature of the hot mold (casting mold heating section) is 1200°C, the cooling water flow rate of the cold mold (water-cooled copper sleeve) is 700L / h, and the pulling speed is 150mm / min.

[0038] (3) The tube blank...

Embodiment 3

[0044] Embodiment 3: The production method of BFe10-2-1 white copper coil with a size of Φ15×1mm

[0045] (1) Electrolytic nickel with a weight percentage of 10.0wt%, pure iron with a weight percentage of 1.8wt%, and 100% by weight

[0046] Pure manganese with a ratio of 1.0wt% and the balance of electrolytic copper are added to the melting furnace, heated to 1250°C for melting, and the molten metal is transferred into the holding furnace, and the standing time is 0.5 under the temperature of the holding furnace at 1200°C. h, while inert gas protection is passed through the holding furnace.

[0047] (2) A hot-cold combined mold horizontal continuous casting process is used to prepare a cupronickel alloy tube billet with a diameter of Φ50×5mm.

[0048] The temperature of the hot mold (mold heating section) is 1200°C, the cooling water flow rate of the cold mold (water-cooled copper sleeve) is 600L / h, and the pulling speed is 150mm / min.

[0049] (3) The tube billet prepared in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com