Production line for treating surface of annular piston

A technology of surface treatment and annular piston, which is applied in the direction of liquid chemical plating, metal material coating process, coating, etc., can solve the problems of high labor intensity, manual control, large investment, etc., and achieve the solution of batch size, cost and production efficiency Improve and realize the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

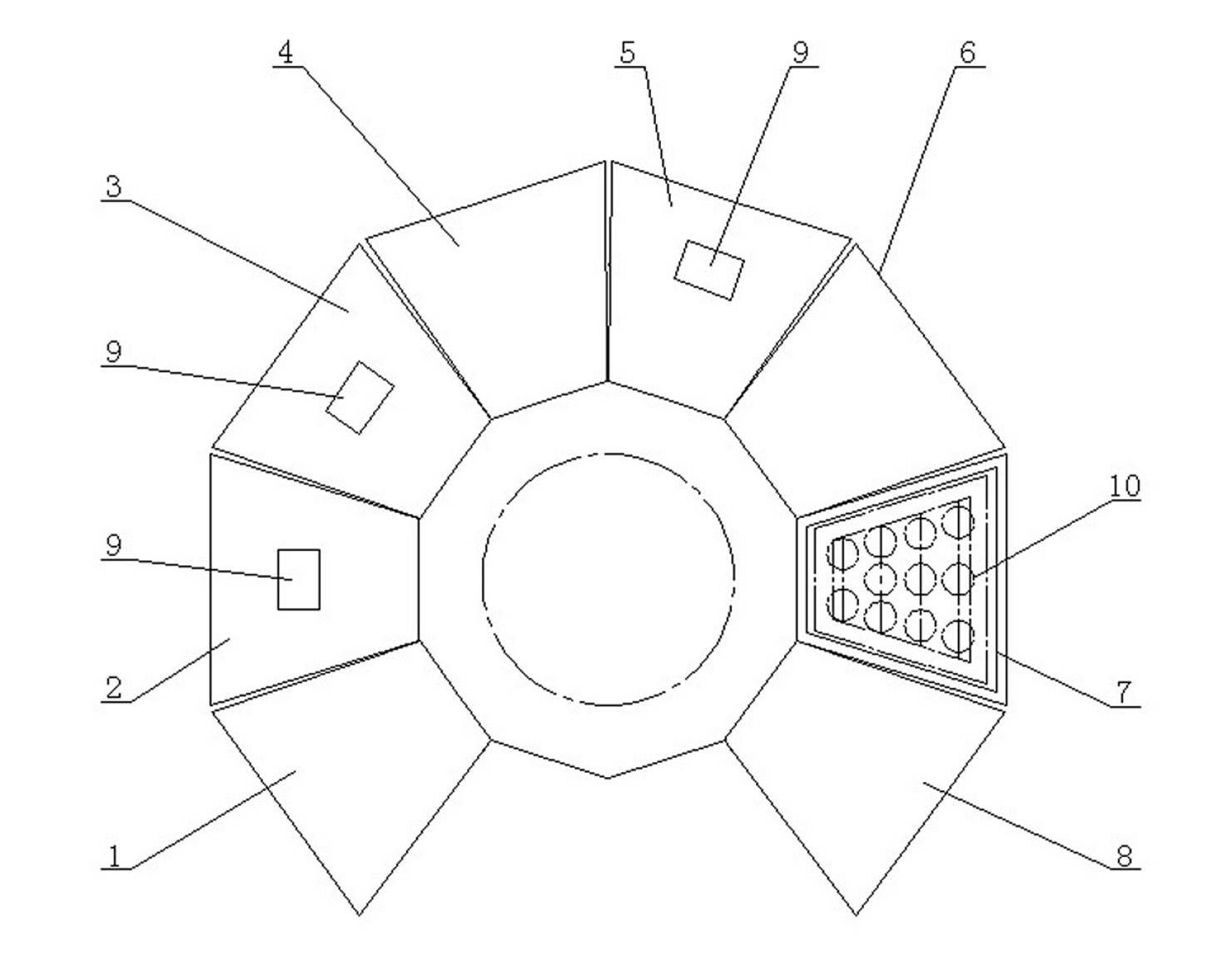

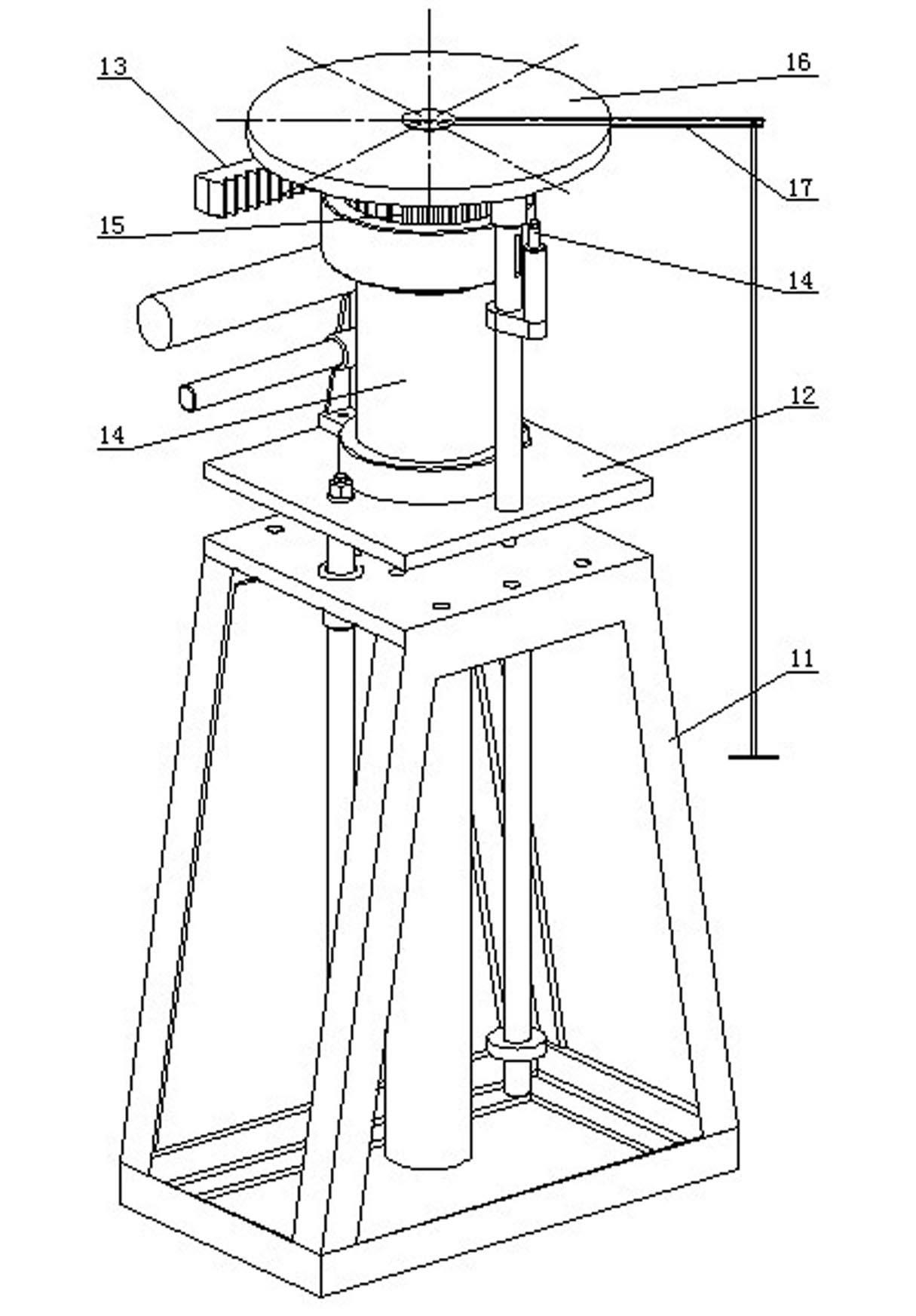

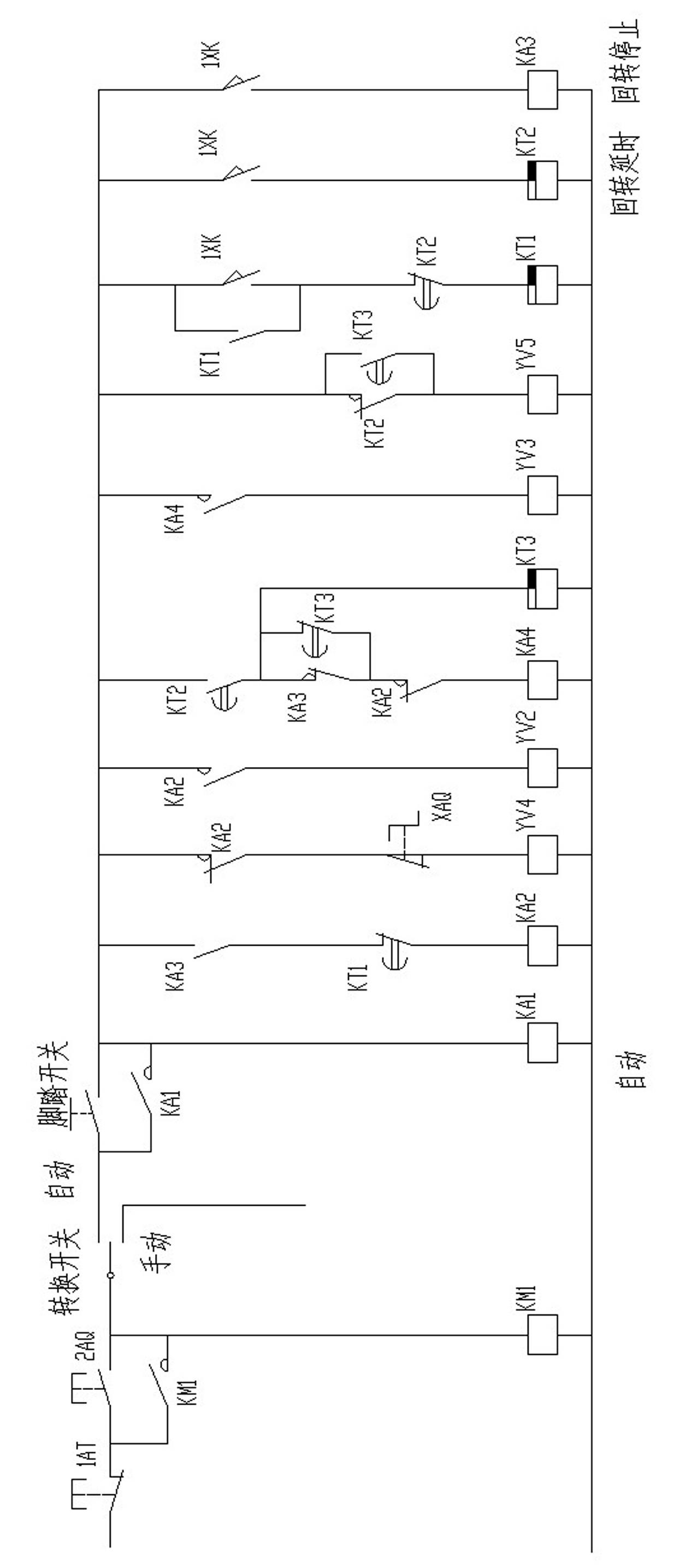

[0011] Depend on figure 1 It can be seen that the annular piston surface treatment production line of the present invention includes several liquid tanks according to the requirements of the piston surface treatment process. There are 8 liquid tanks in this embodiment. The surface shape of the liquid tanks is trapezoidal, and each liquid tank is arranged in an arc along the hypotenuse. Clockwise, there are lye ultrasonic cleaning liquid tank 1, ultrasonic hot water rinsing liquid tank 2, flowing cold water rinsing liquid tank 3, acid photochemical liquid tank 4, ultrasonic flowing cold water bleaching liquid tank 5, chemical tin plating or chemical phosphorus Chemical solution tank 6, flowing cold water rinsing liquid tank 7, hot water rinsing and scalding liquid tank 8. According to the area radius of the arrangement, the external dimensions of the liquid tank can be designed, and at the same time, according to the characteristics of the arrangement, the structure of the ultr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com