Composite paste material and preparation method thereof

A technology of paste and starch, which is applied in the preparation of the above-mentioned compound paste, compound paste, and paste for printing, which can solve the problems of poor printing uniformity, low color supply, and poor printing outline definition, and achieve cost savings , improved economic benefits, and excellent print penetration uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The preparation method of compound paste of the present invention, specifically implement according to the following steps:

[0018] Step 1: Weigh the modified starch, dragon gum, guar gum, Arabic gum and water according to the mass ratio of 5-7:1-3:1:1:1-2, mix, heat to 25-35°C, and stir Evenly, continue to stir into a thick paste, set aside to make a compound paste.

Embodiment

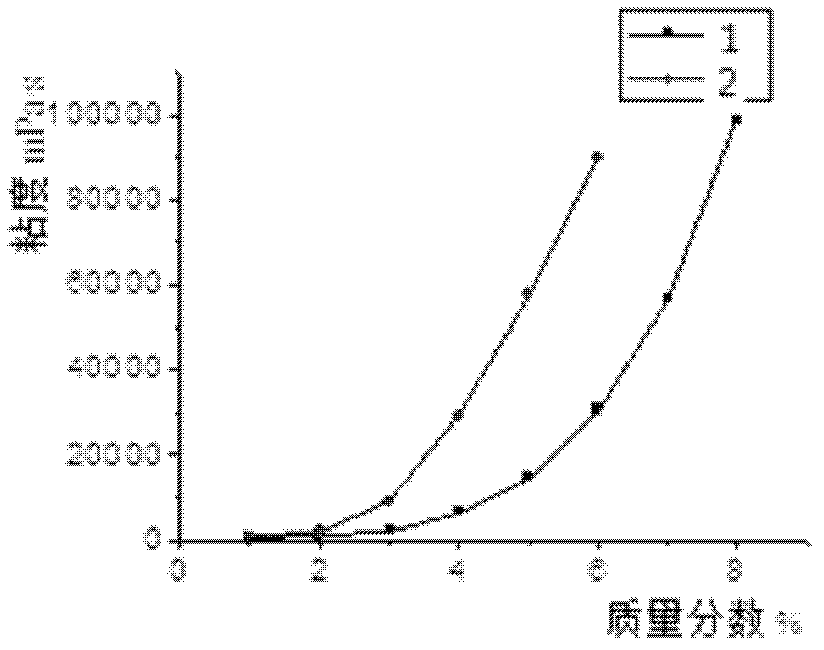

[0020] The composite paste prepared when the modified starch content is 50%-70% is made into a composite paste with a solid content of 3%, 5%, and 7%. The paste-forming rate curve is as follows: figure 1 shown.

[0021] figure 1 It shows that after compounding the compound original paste, when the modified starch paste content is 60%, the viscosity has reached 10,000 when the solid content is 3%. With the increase of solid content, the viscosity gradually increases, showing a linear relationship. It shows that under the same viscosity, the composite raw paste compounded under different proportions has the lowest solid content when the content of modified starch is 60%, which can be explained that printing with this raw paste can save production costs.

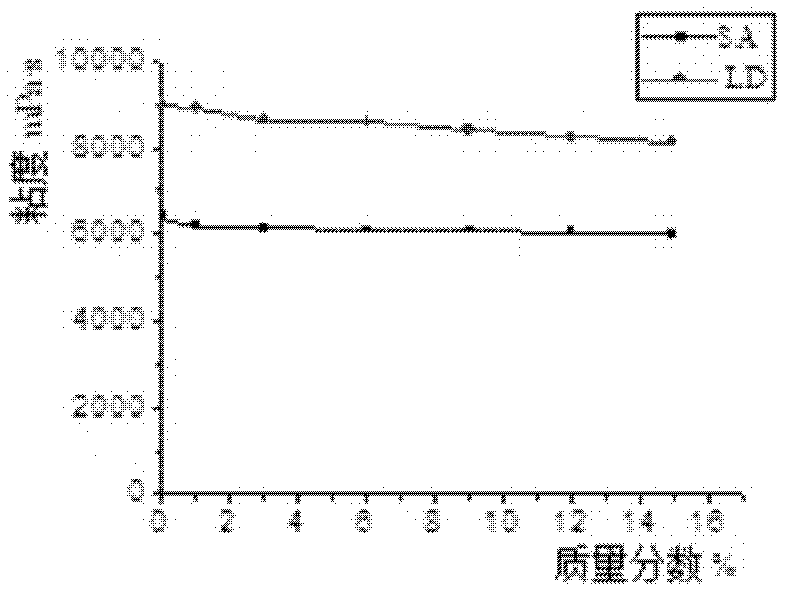

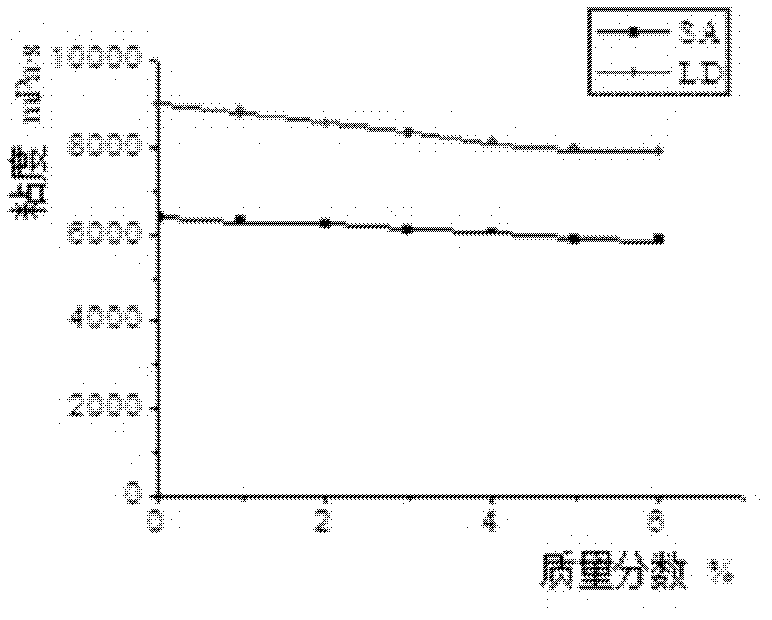

[0022] When the modified starch content is 60%, the dragon gum paste is 10%-30%, the guar gum paste is 10%-20%, and the arabic gum paste is 10%-20%, the compound raw material with the same viscosity can be made. Paste, its pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com