Suspension type anti-vibration member

A technology of anti-vibration parts and suspension, which is applied in the direction of anti-vibration, building components, non-rotational vibration suppression, etc. It can solve the problems of time-consuming vibration anti-vibration parts, reduction of vibration absorption effect, damage, etc., and achieve reliable anti-vibration effect and thickness Effect of reduction, durability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

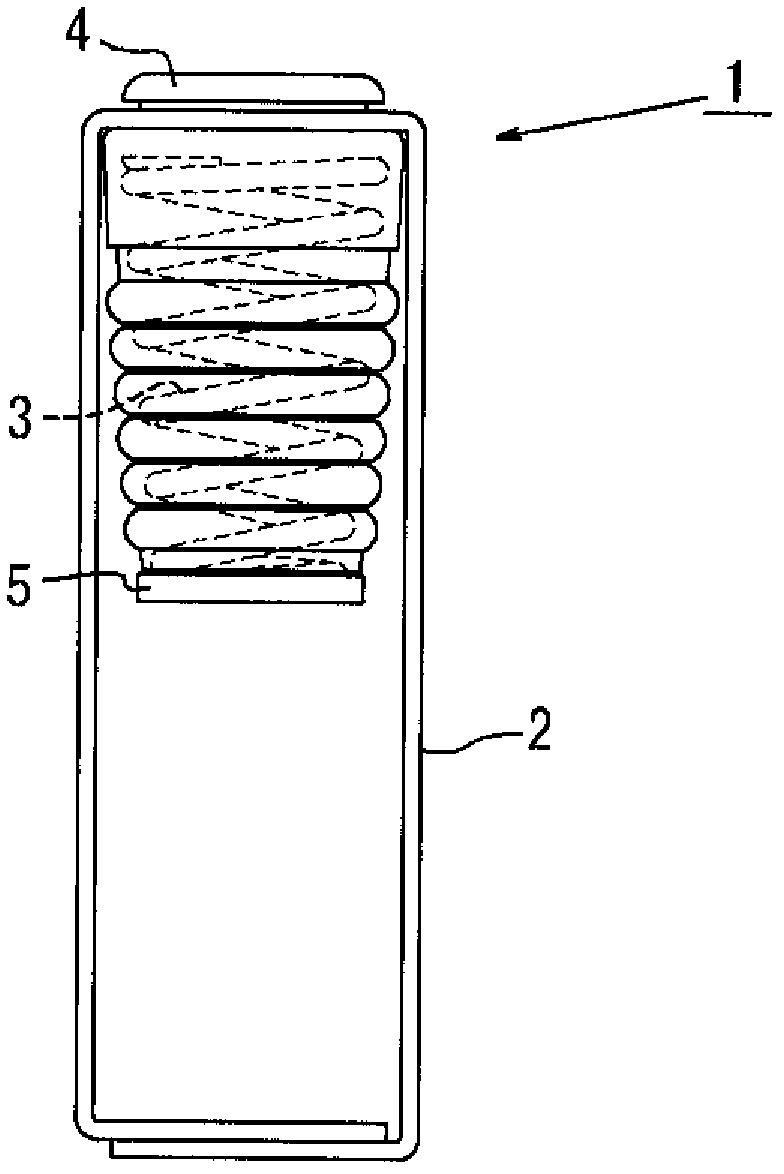

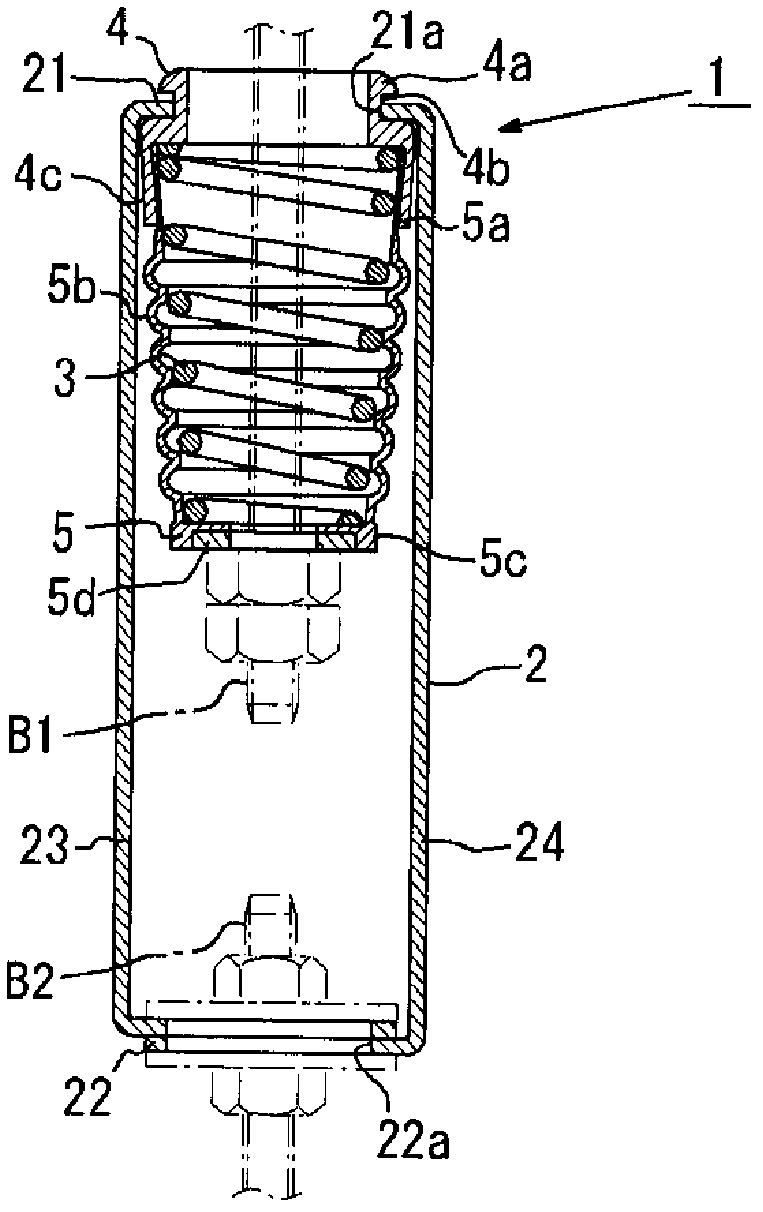

[0045] use Figure 1 to Figure 8 The suspension type anti-vibration material according to the embodiment of the present invention will be described.

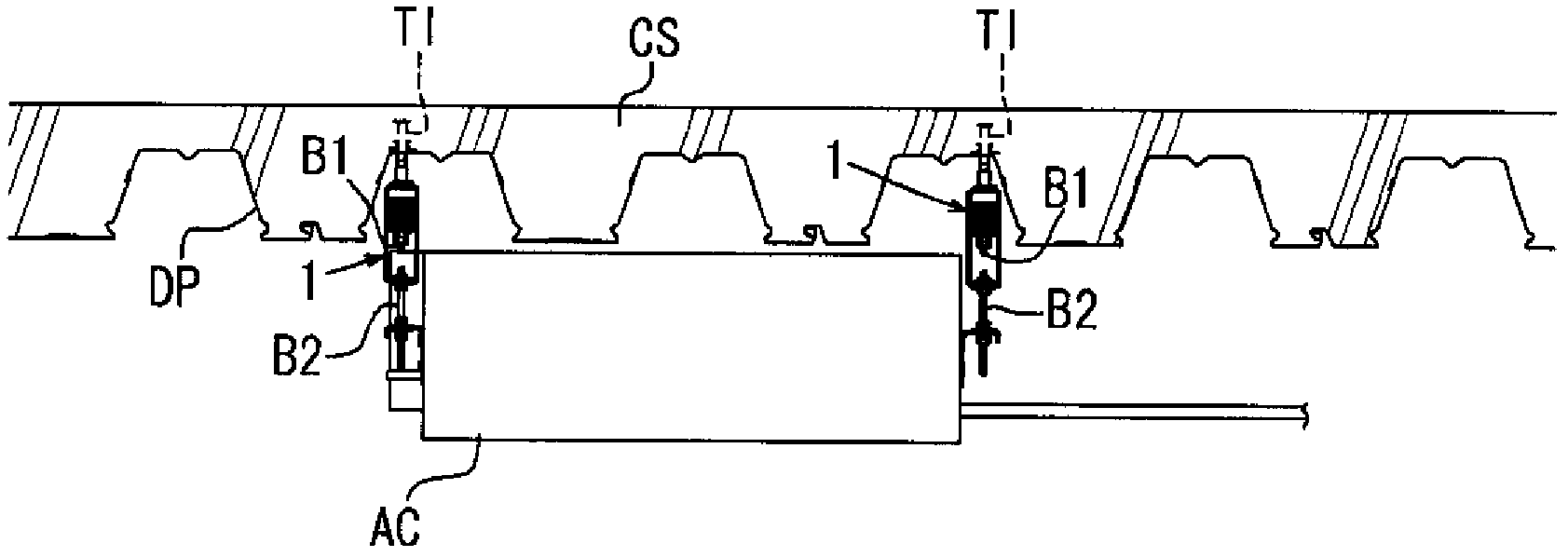

[0046] figure 1 It is an explanatory diagram showing the use state (installation state) of the suspension type vibration isolator according to the embodiment of the present invention. exist figure 1 Among them, AC is an air conditioner exemplified as an embodiment of a vibrating device that generates vibration, and reference numeral 1 is an anti-vibration suspension exemplified as an embodiment of the suspension-type anti-vibration material of the present invention. Such as figure 1 As shown, the air conditioner AC is suspended and supported on the concrete floor CS on the upper floor as the structural main body by suspension bolts (upper suspension bolt B1, lower suspension bolt B2), and the suspension bolts are formed on the corrugated steel plate DP at predetermined intervals (usually 900 mm) Spacing) The pre-installed ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com