Replaceable connecting joint for wallboard components of precast concrete shear wall structures

A prefabricated concrete, connecting node technology, applied in building components, walls, building structures, etc., can solve problems such as plastic deformation, weak and sensitive parts, and the replacement of connecting areas is not considered, to ensure integrity and safety, avoid Damage and Destruction Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

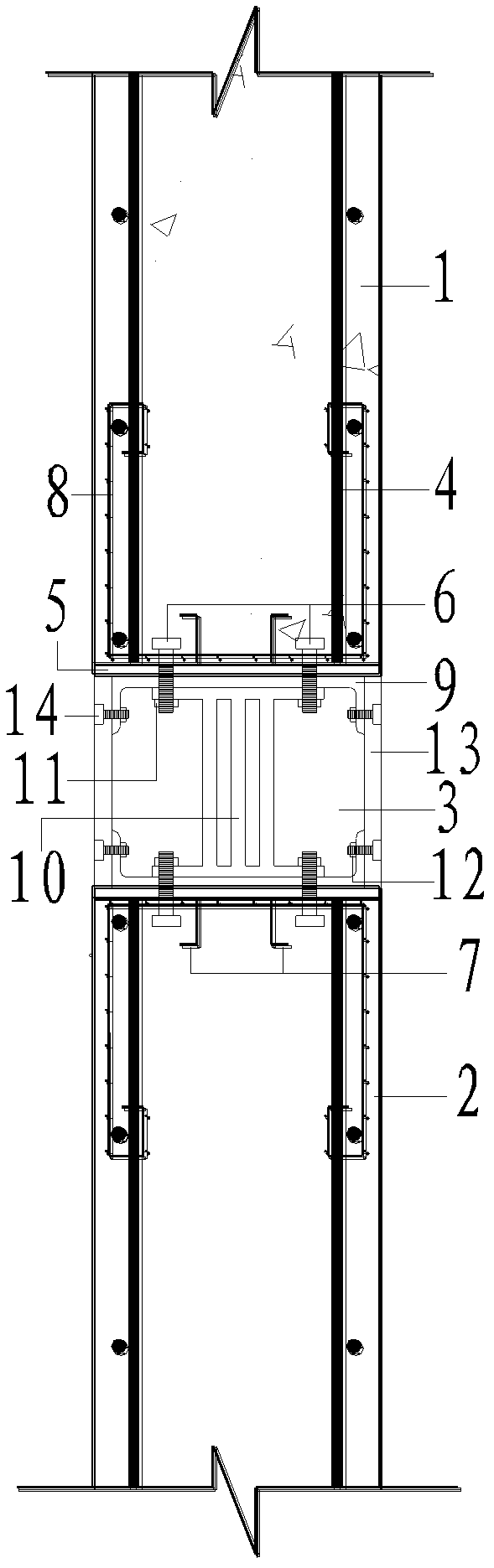

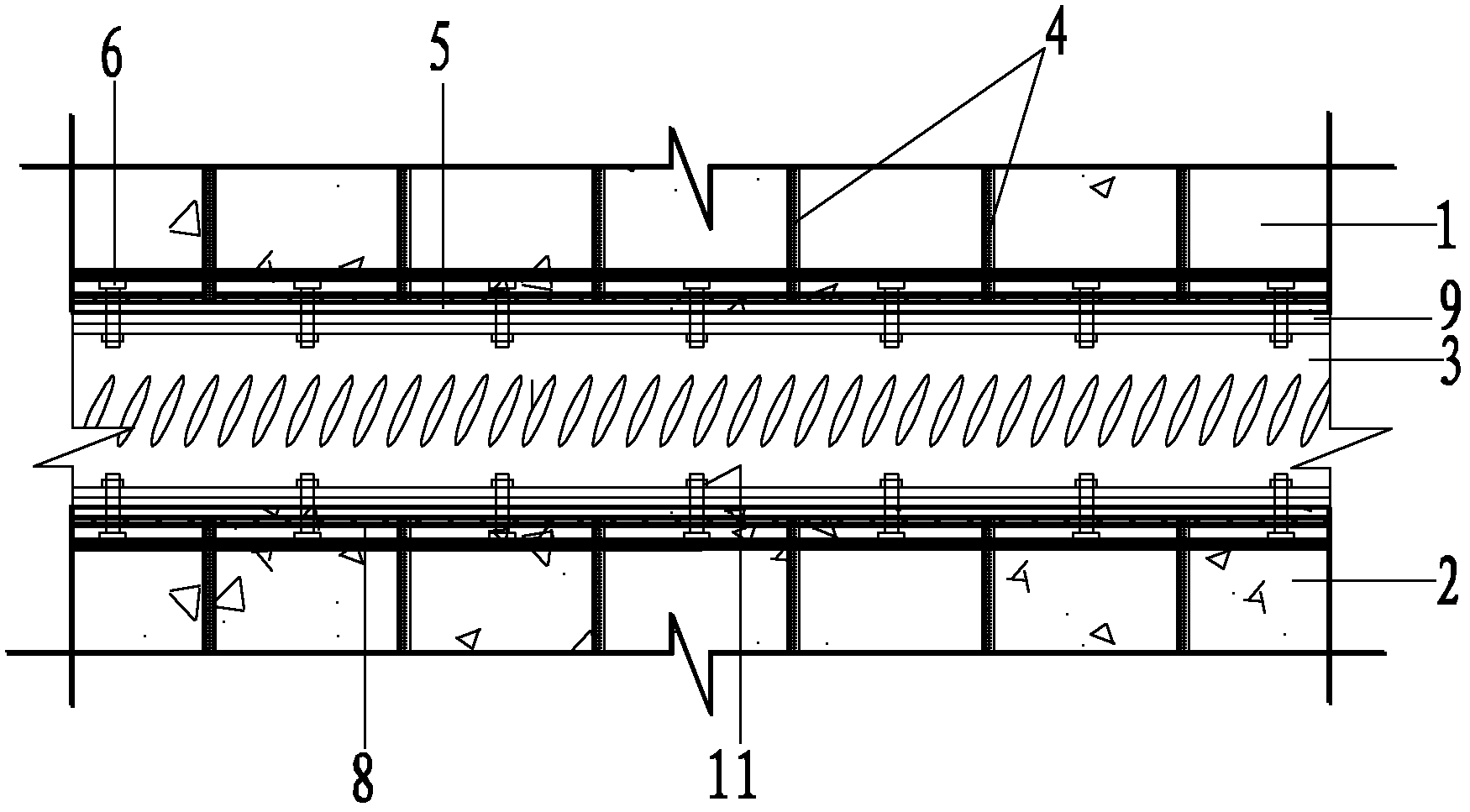

[0039] Such as figure 1 As shown, it is a schematic diagram of the overall structure of the replaceable connection nodes of the wall panel members of the precast concrete shear wall structure of the present invention.

[0040]A replaceable connection node of a prefabricated concrete shear wall structure wall panel member, the replaceable connection node includes a first prefabricated concrete shear wall panel 1, a second prefabricated concrete shear wall panel 2 and a node part 3, the first prefabricated concrete The shear wall panel 1 is connected with the second prefabricated concrete shear wall panel 2 through the node part 3 .

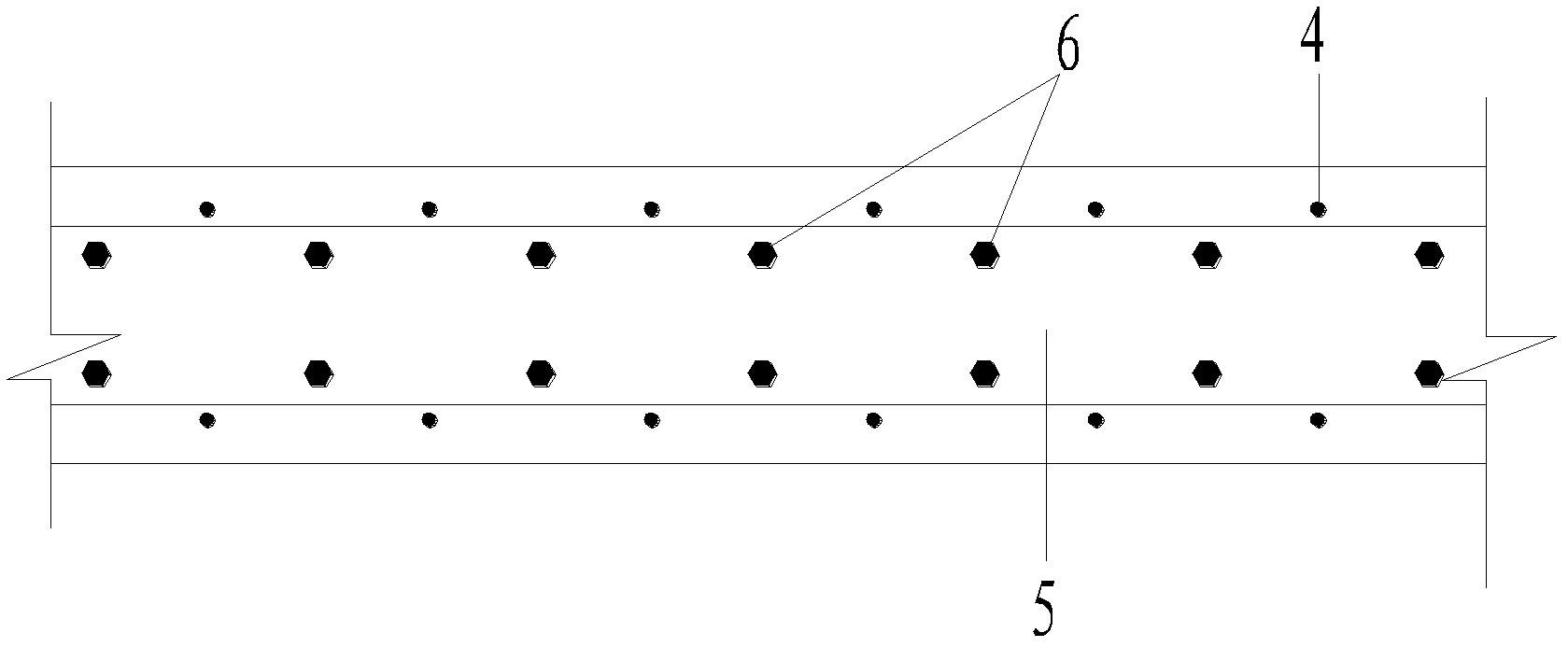

[0041] Such as Figure 11 As shown, it is a front view of the connection of the embedded steel plate, the second high-strength bolt, the short anchoring steel bar and the thin steel mesh at the replaceable connection node of the wall panel member of the prefabricated concrete shear wall structure of the present invention. The first prefabricated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com