Door body structure of steel-concrete combined protection door and manufacturing method of door body structure

A technology for concrete and protective doors, applied in windows/doors, building components, door/window applications, etc., can solve problems such as easy buckling, unreasonable material utilization, material waste, etc., to improve bending performance and impact resistance , save the amount and increase the rigidity of the door body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

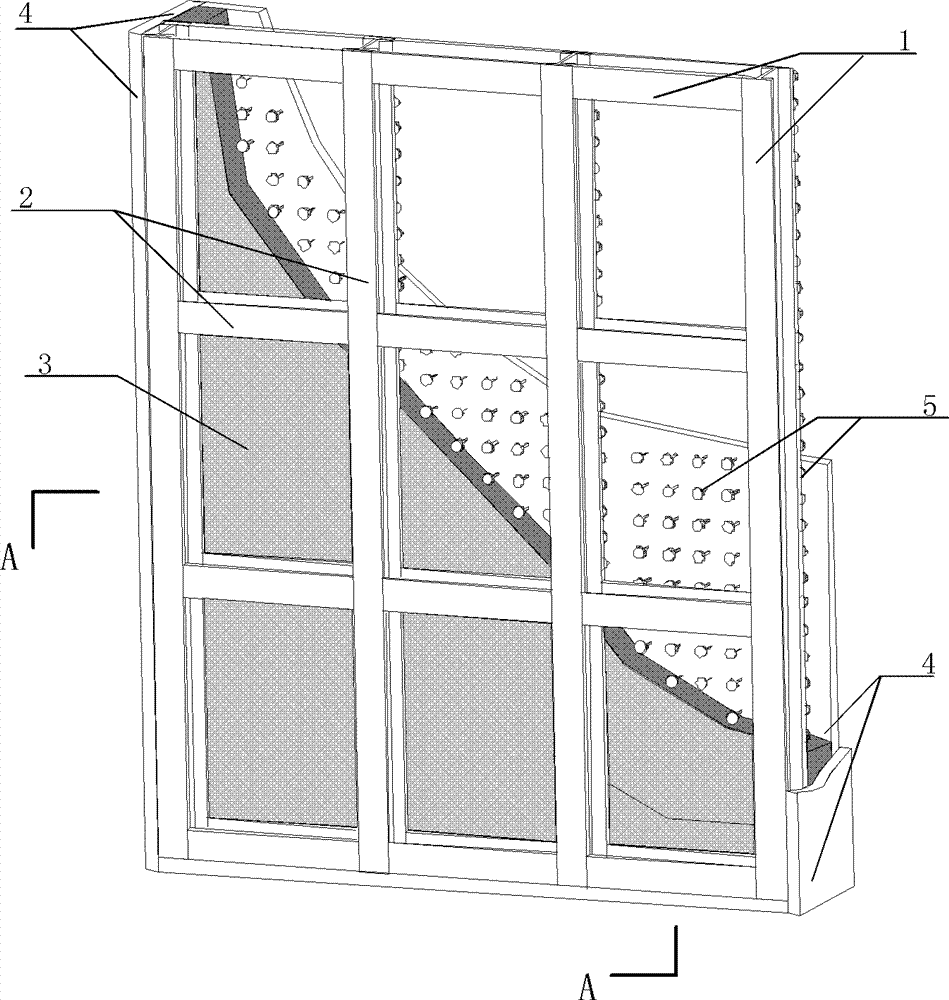

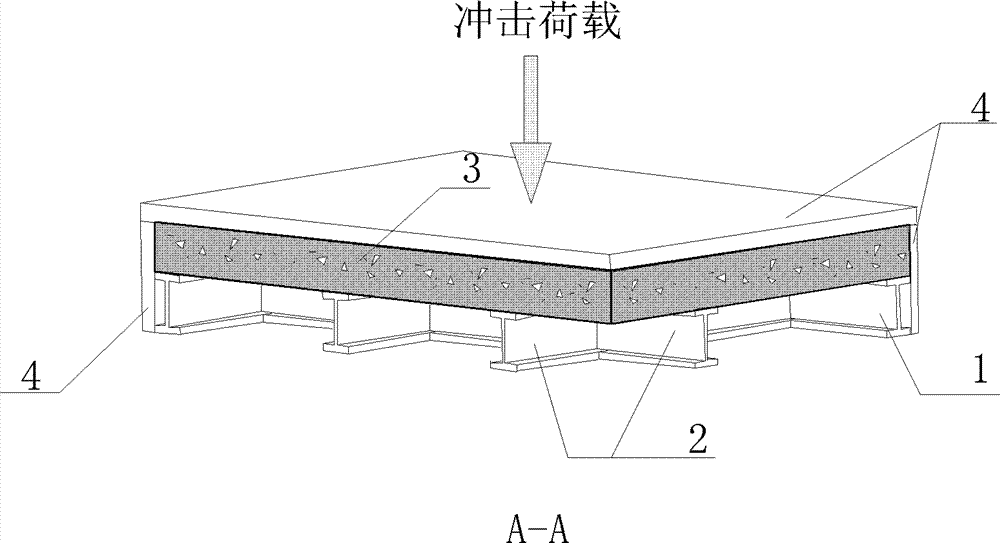

[0019] The door structure of a steel-concrete composite protective door provided by the present invention includes a steel structure part and a concrete slab 3, and the steel structure part includes a steel frame 1, a two-way steel beam 2, and an outsourcing steel plate 4, wherein the steel frame 1 adopts The I-shaped steel beam is located around the two-way steel beam 2, and the steel frame 1 and the two-way steel beam 2 can be fixed together by bolts or welding; the two-way steel beam 2 is also an I-shaped steel beam, located inside the steel frame 1, The connection between the two-way steel beams can be fixed together by bolt connection or welding. The number of steel beams, cross-sectional size and steel beam spacing are determined according to the use requirements. The outsourcing steel plate 4 covers the impacted surface, the side elev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com