Self-balancing large-diameter bolt and special mechanical torque wrench device for same

A self-balancing, torque wrench technology, applied in the engineering field, can solve the problems of reduced connection reliability, limited application scope, reduced torque accuracy, etc., and achieves the effect of improving disassembly efficiency, increasing application scope, and ensuring reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

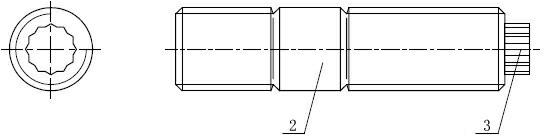

[0044] A self-balancing large-diameter bolt, such as figure 2 As shown, taking the stud bolt structure as an example, it includes a bolt body 2, and the threaded end of the bolt body 2 has a positioning section of a non-circular cross-section structure, and the positioning section of the non-circular cross-section structure is located at the bottom of the bolt body 2. A non-circular section positioning section 3 extending outward from the end of the thread, the axis of the non-circular section positioning section 3 is coaxial with the thread of the bolt body 2 .

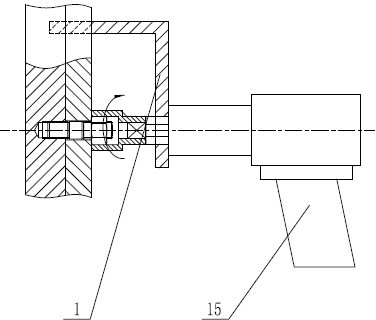

[0045] Such as Figure 6 and 7As shown, a special motorized torque wrench device for the above-mentioned self-balancing large-diameter bolt connection includes a common motorized torque wrench 15, such as an electric, pneumatic, hydraulic torque wrench, etc., at the power output end of the common motorized torque wrench 15 A torque conversion joint is provided, and the torque conversion joint includes a box body 1...

Embodiment 2

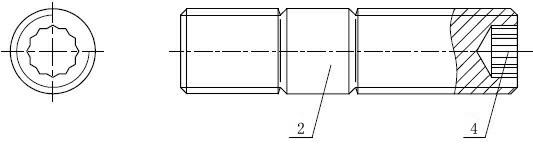

[0053] A self-balancing large-diameter bolt, such as image 3 As shown, taking the stud bolt structure as an example, it includes a bolt body 2, and the threaded end of the bolt body 2 has a positioning section with a non-circular cross-section structure, and the positioning section of the non-circular cross-section structure is on the bolt body 2 , the non-circular section positioning groove 4 provided at the end of the thread. Such as Figure 8 The above is a schematic diagram of the structure of the torque conversion joint matching the above-mentioned bolt structure, wherein the positioning end of the inner positioning sleeve 7 is a structure that cooperates with the non-circular cross-section positioning groove 4 of the bolt, and other structures and working principles are the same as those in Example 1. basically the same.

Embodiment 3

[0055] A self-balancing large-diameter bolt, such as Figure 4 with 5 Shown is a schematic diagram of a single-head bolt structure, with a positioning section of a non-circular cross-section structure at the thread end of the bolt body, and the positioning section of the non-circular cross-section structure is the same as the two structural forms in Embodiment 1 and Embodiment 2. ; The special motorized torque wrench device used for the single-head bolt connection of the above two structural forms is the same as the structure described in Embodiment 1 and Embodiment 2 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com