High-pressure quick-mount flange

A quick-installing flange, high-pressure technology, applied in flange connection, pipe/pipe joint/pipe fitting, through components, etc., can solve the problems of short practical life, complicated processing, high cost, and achieve simple and easy installation and good sealing effect. , the effect of easy procurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

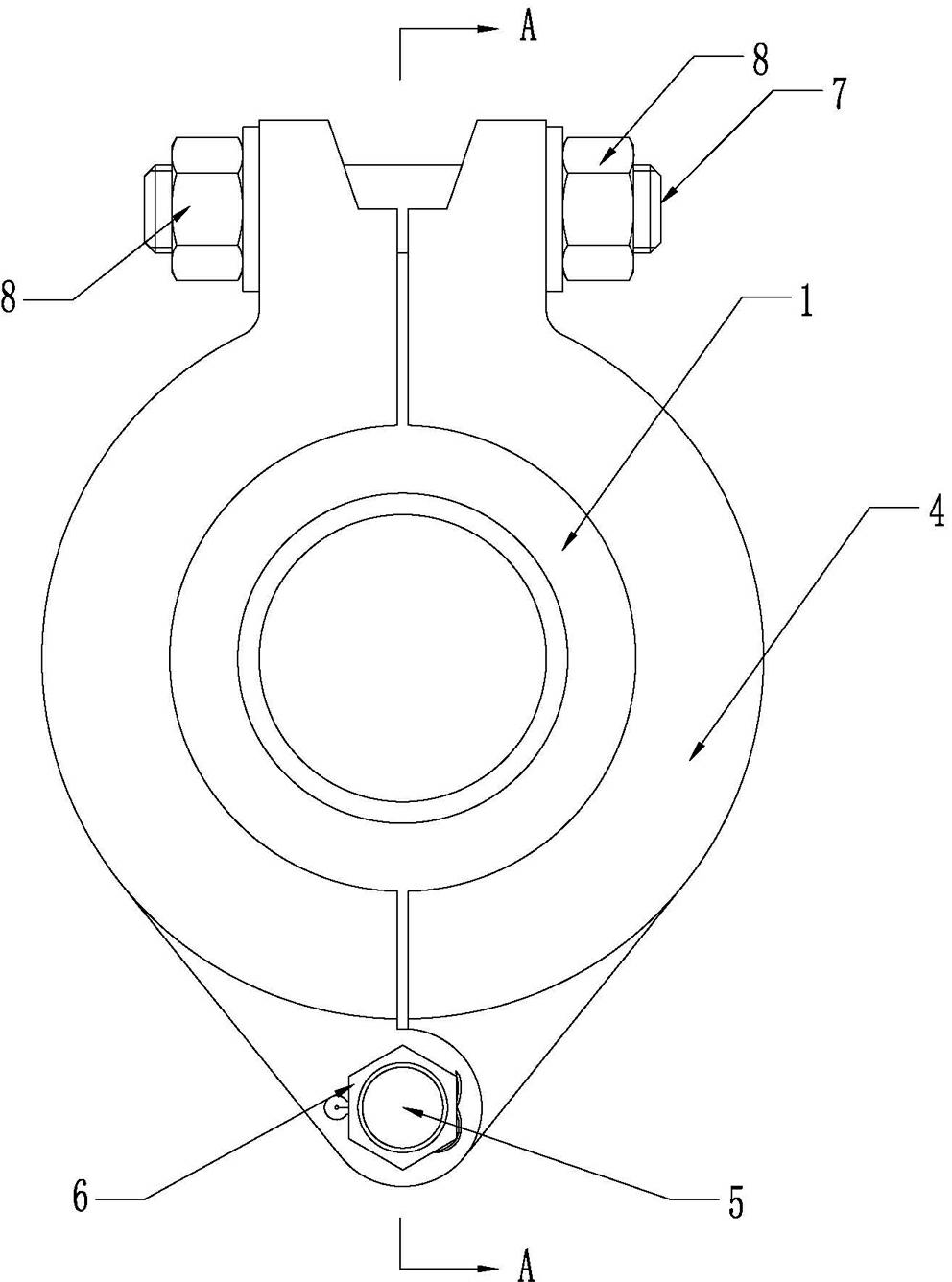

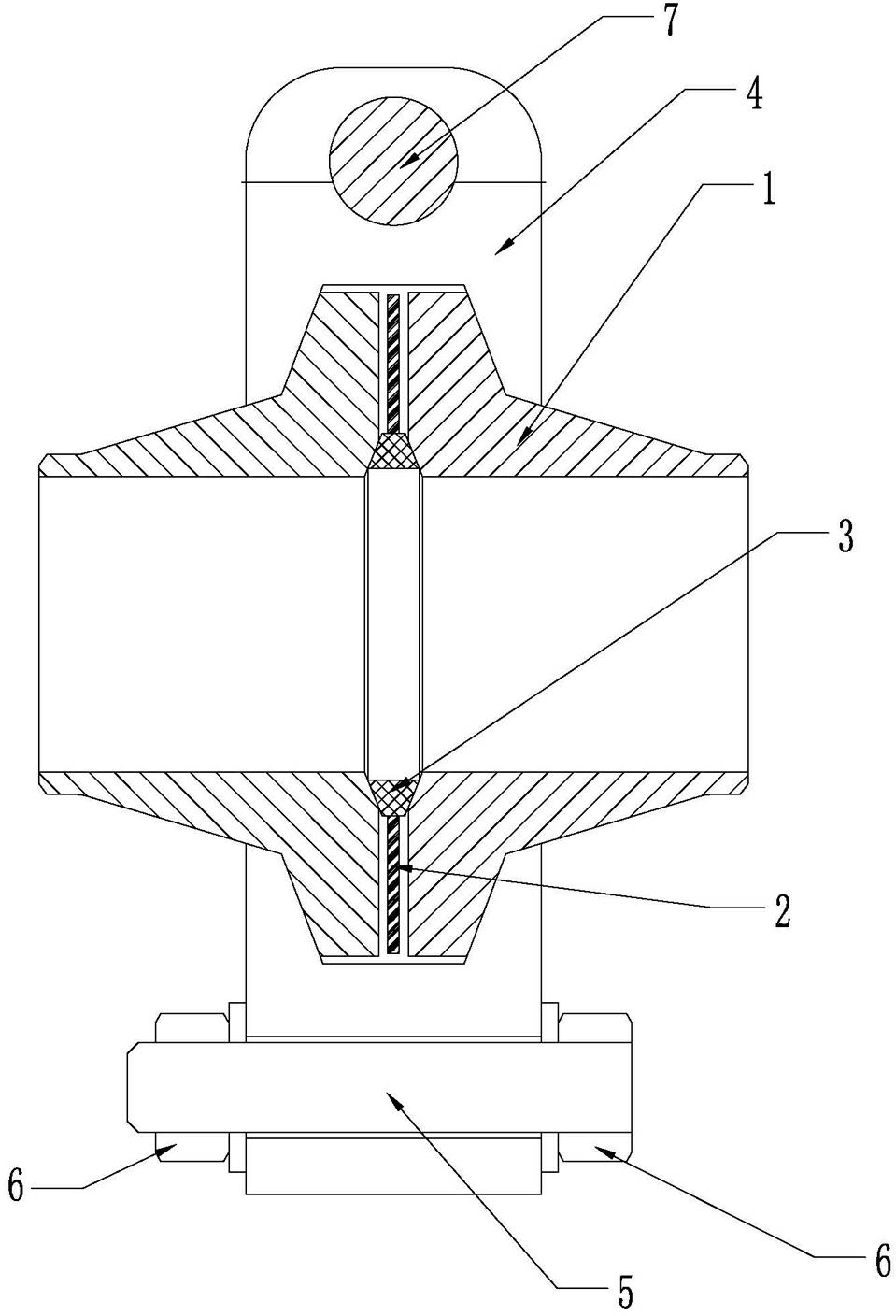

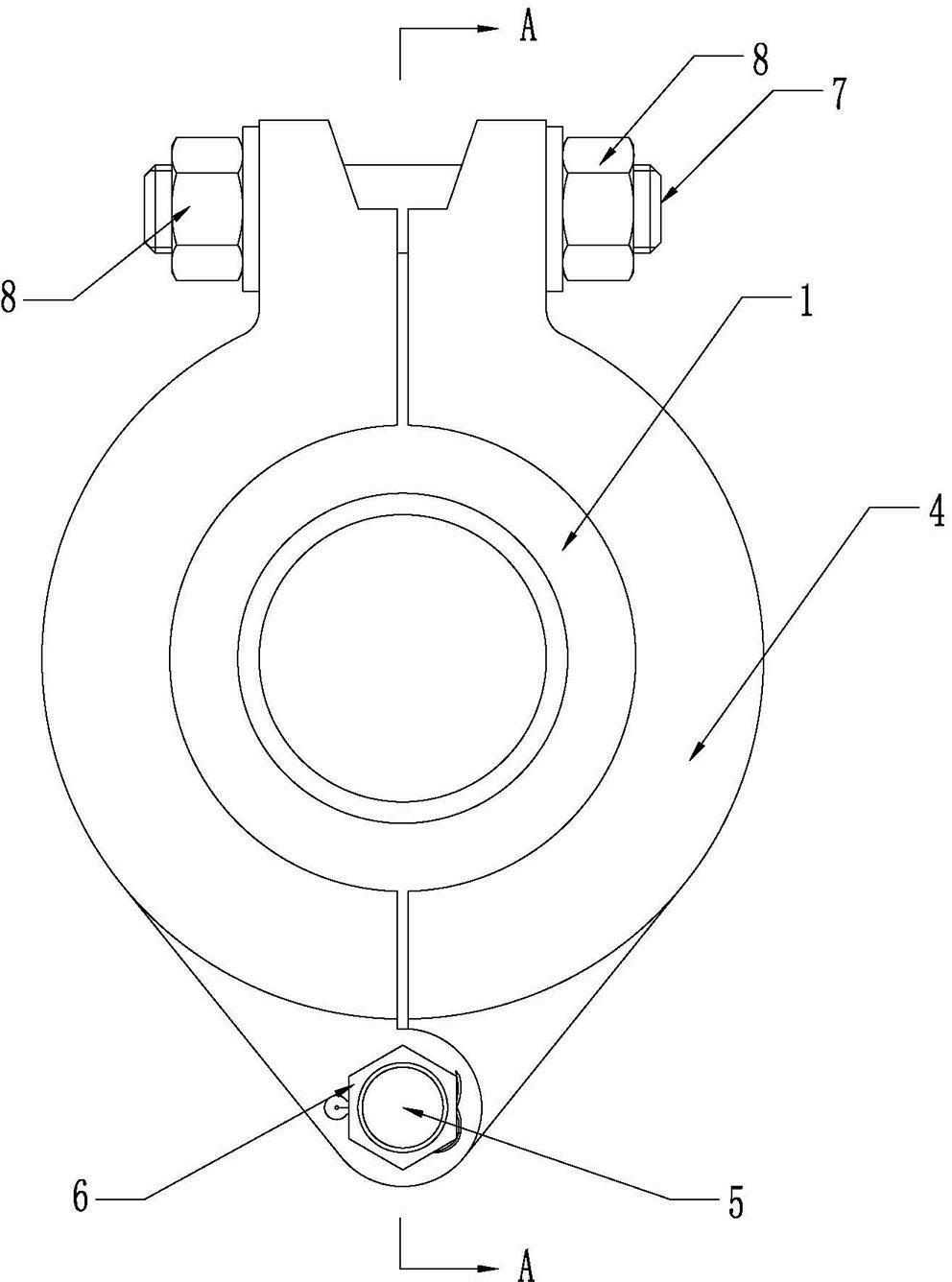

[0014] Such as figure 1 with figure 2 A high-pressure quick-fit flange is shown, which is characterized in that it includes two pairs of welding rings 1, positioning ring 2, lens pad 3, two half-piece clamps 4, positioning bolts 5, positioning nuts 6, fastening bolts 7 and tightening Fixing nut 8, the positioning ring 2 is installed between the two pairs of welding rings 1, the lens pad 3 is installed on the inside of the positioning ring 2, and the two half-piece clamps 4 are installed on the outside of the two pairs of welding rings 1, through the positioning bolt 5 and the positioning nut 6 Connect one end of the two half-piece clamps 4 , and fasten the other ends of the two half-piece clamps 4 through fastening bolts 7 and fastening nuts 8 .

[0015] The connection method of the present invention is as follows: two pieces of butt welding rings 1 are respectively welded to the two pipes to be butted, the lens pad 3 is loaded into the positioning ring 2, and then the posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com