Heat exchanger for fluidizing type water heater

A heat exchanger and water heater technology, applied in the direction of heat exchanger types, indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of low heat exchange efficiency and energy waste, save water tank space and reduce refrigerant exchange. incomplete effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

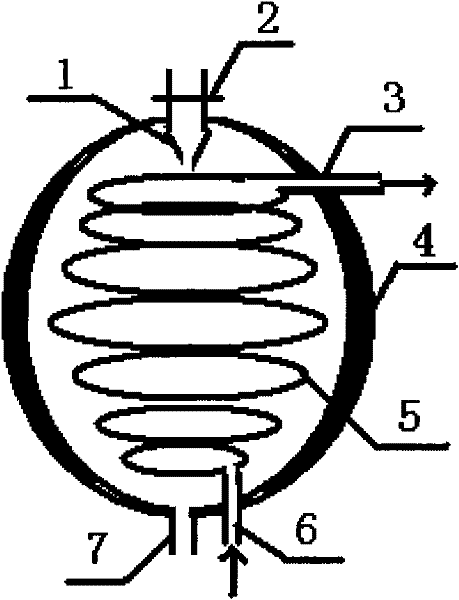

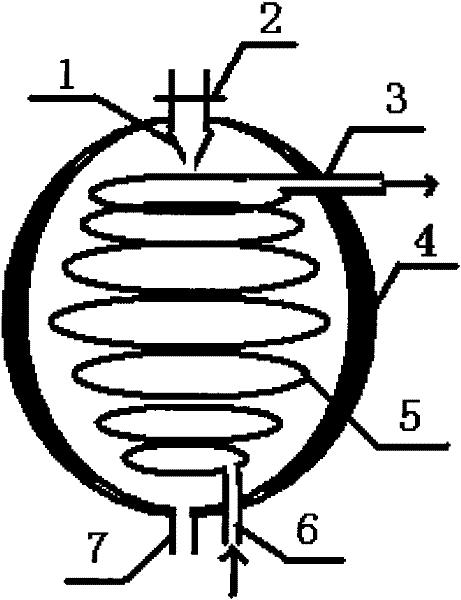

[0011] Below in conjunction with accompanying drawing, the present invention is further described: this heat exchanger comprises: shell, water pipe coil 5, spout 1, return pipe 7 and throttle valve 2, and its water tank is heat exchange box, and box body is a spherical shell body, a plurality of water pipe coils 5 are arranged in the tank, the water pipe coils 5 are spaced apart from each other, and the water pipes 4 on the water tank wall are spirally close to the spherical pipe wall of the tank body. There is a throttle valve 2 and a refrigerant nozzle 1 at the top of the water tank, and a refrigerant return pipe 7 is provided at the bottom of the water tank. The cold water inlet 6 at the lower end enters the water pipe coil 5 and the water pipe 4 on the wall of the water tank. After heat exchange, it turns into high-temperature water and flows out from the hot water outlet 3 at the upper end of the water tank. The return pipe 7 flows out of the heat exchange box.

[0012] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com