Automatic tester for valve lift and timing phase of engine

An automatic test device and engine valve technology, which is applied in the direction of engine test, measurement device, machine/structural component test, etc., can solve the problem of large volume, inability to measure valve displacement in real time, system volume and configuration difficult to meet the dynamic requirements of the engine, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

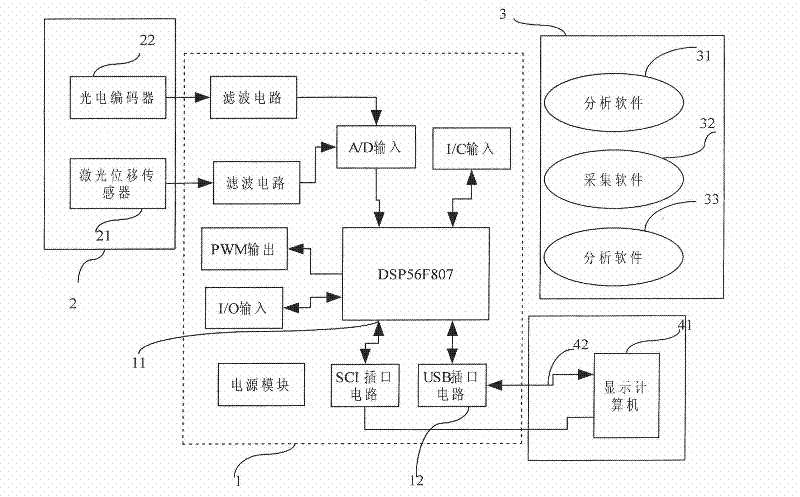

[0027] The engine valve lift and valve timing automatic test device consists of three parts, as attached figure 1 As shown, 1. The hardware of the signal acquisition part is composed of the acquisition unit 1 and the acquisition accessory 2; 2. The system software part 3 is composed of the acquisition software 31, the data analysis software 32, and the data display software 33; 3. The data transmission and display 4 is composed of Data line 41 and display computer 42 form.

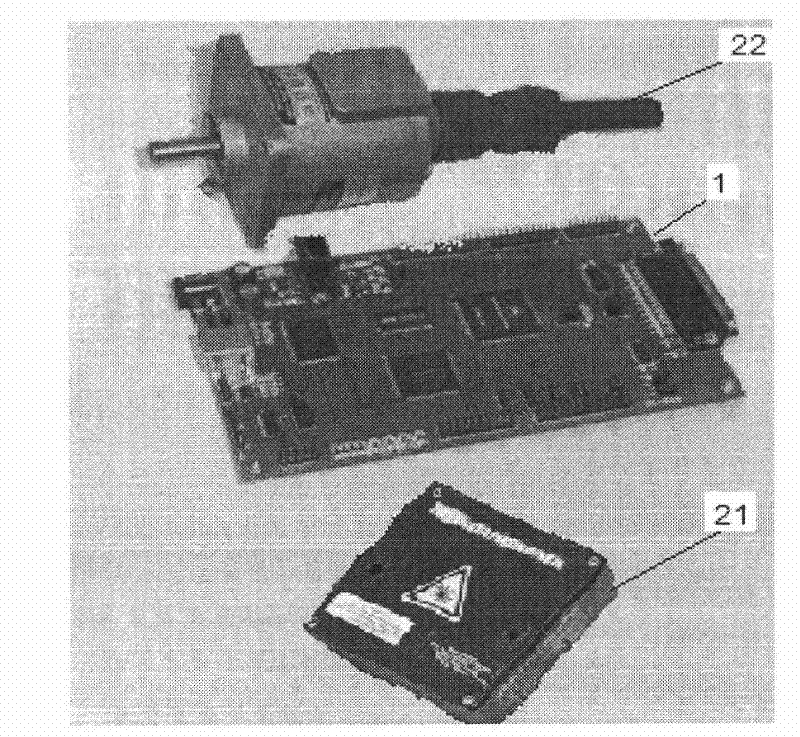

[0028] The acquisition unit 1 is composed of a digital signal processor 11 and a USB plug-in 12, and the acquisition accessory 2 is composed of a laser displacement sensor 21 and a photoelectric encoder 22, as shown in the attached figure 2 shown.

[0029] Digital signal processor 11 selects the digital signal processor DSP56F807 of Freescale Company for use, and it is the special-purpose microprocessor of processing real-time signal, can reach the order execution speed of 40 trillion instructions / S (MI...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com