Field dynamic balance measuring device and method for utility boiler side fan

An on-site dynamic balancing and measuring device technology, applied in measuring devices, static/dynamic balance testing, and machine/structural component testing, etc., can solve problems such as delays in power generation production work, unreasonable structural design, and unbalanced impeller quality. , to achieve the effect of convenient data comparison and later data analysis, high on-site dynamic balancing accuracy, and reducing the number of starts and stops

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

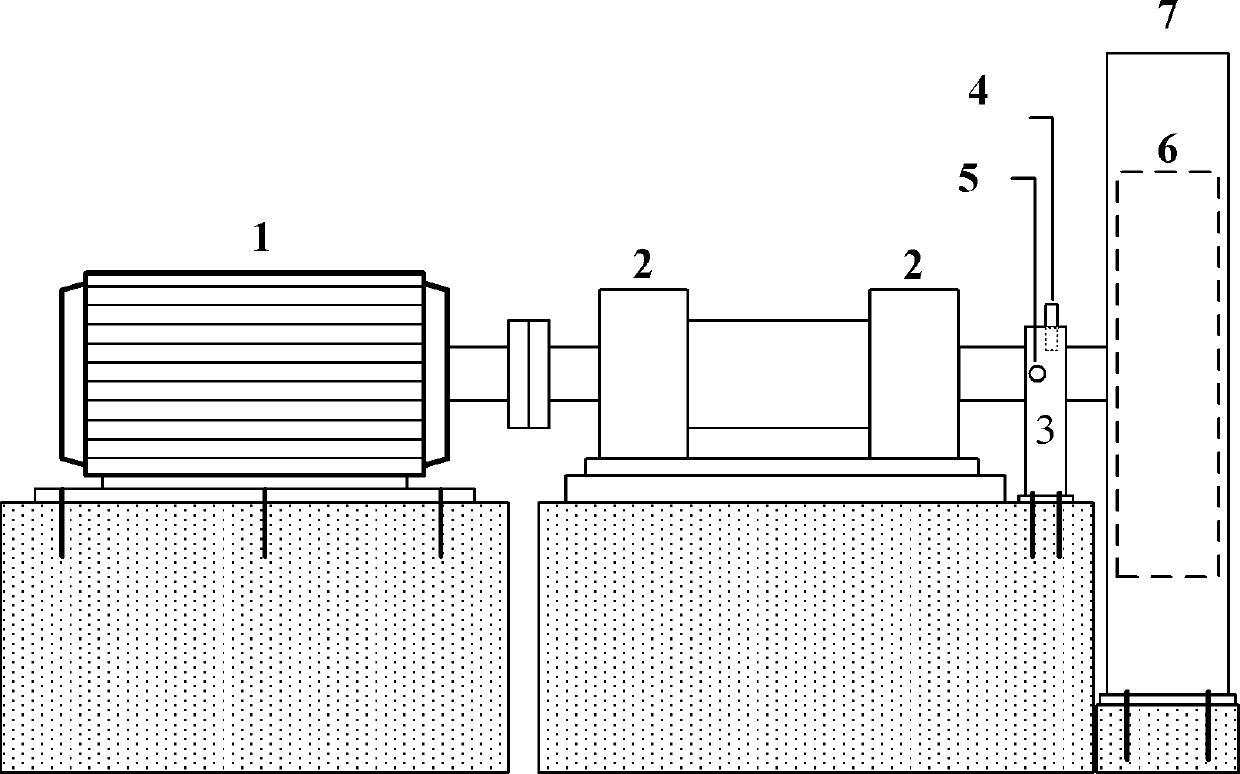

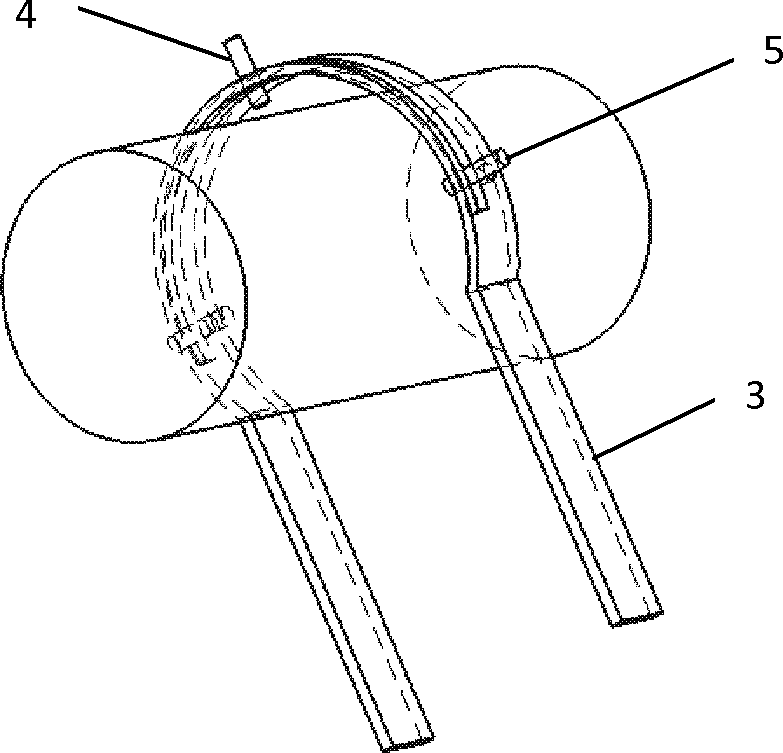

[0045] figure 1 , figure 2 Among them, a fan casing 7 is arranged outside the impeller 6, and the impeller shaft of the impeller 6 is connected with the motor 1 through a bearing 2. Set the bracket 3 on the impeller shaft, install a key phase probe 5 at the horizontal position of the bracket 3, open a groove structure on the side of the key phase probe 5 on the bracket 3 along the circumference, and slide and install two measuring axes in the groove structure Shaft vibration probe 4. The two axial vibration probes 4 are arranged in a horizontal direction and a vertical direction, or arranged at an angle of 45° left and right.

[0046] Dynamic balancing method of the present invention is:

[0047] Step 1. Use the shaft vibration probe 4 and the key phase probe 5 to directly read the vibration value, including power frequency amplitude and phase angl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com