Performance test table for rear shock absorber

A shock absorber and test bench technology, which is applied to vehicle suspension/shock absorber testing and other directions, can solve the problems of high price, difficult control, complex control system, etc., and achieve the effect of convenient control and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

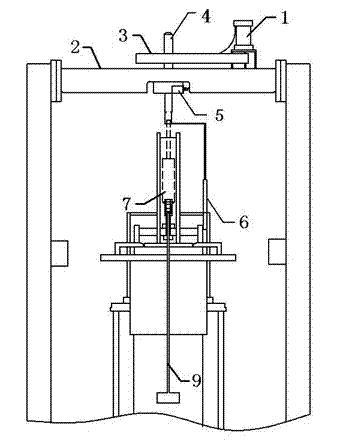

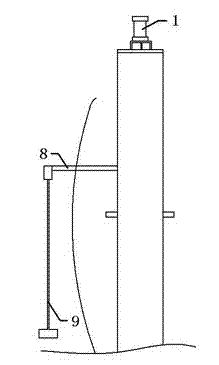

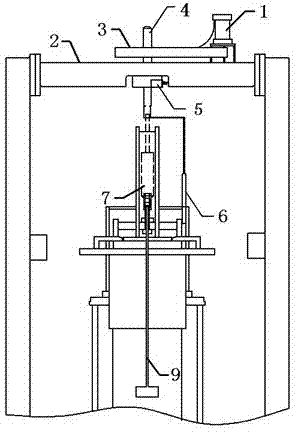

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0012] As shown in the figure, the test bench of the present invention includes a base, a crossbeam 2, a crossbar 8, a column, etc., a motor 1 is located above the crossbeam 2, a straight rod 4 passes through the crossbeam 2 vertically, and is connected with the motor 1 through a transmission system 3. Transmission system 3 comprises pinion, bull gear and drive belt.

[0013] During the test, the rear shock absorber 7 is installed on the test bench, and the weighing weight is loaded on the beam 9 as required. Then the straight rod 4 is driven by the motor 1, and slowly descends along the axis of the straight rod 4, and the piston rod is slowly pressed down (from the free stroke state to the minimum stroke state), and the minimum moving speed can reach 0.005m / s. The force change and displacement change in this process are transmitted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com