Method for measuring temperature-controllable four-probe square resistance and resistivity

A technology of sheet resistance and test method, applied in the field of measurement, can solve the problems of limited application, unable to test sheet resistance and resistivity, etc., and achieve the effects of high sensitivity, compact structure and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

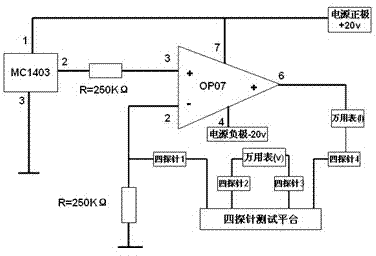

[0023] The present invention provides a method for testing square resistance and resistivity using a temperature-adjustable four-probe square resistance testing system, such as figure 1 As shown, the circuit mainly consists of a MC1403 precision low-voltage reference power supply and an OP07 bipolar operational amplifier. The low-noise, high-precision characteristics of the OP07 bipolar operational amplifier are ideal for amplifying weak signals from sensors. The positive pole of the 20V external power supply with adjustable output voltage is respectively connected to pin 1 of MC1403 precision low-voltage reference power supply and pin 7 of OP07 bipolar operational amplifier, pin 3 of MC1403 precision low-voltage reference power supply is grounded, and pin 2 is connected to Resistor R1 is connected to pin 3 of R1OP07 bipolar operational amplifier. The...

Embodiment 2

[0045] The specific steps for testing resistivity are:

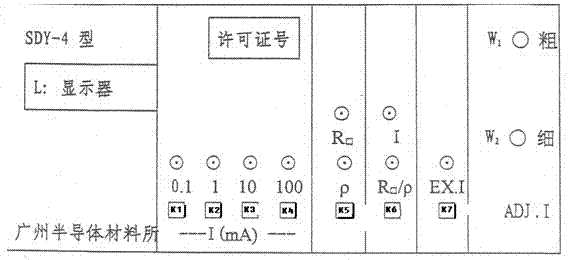

[0046] Step 1: Connect the circuit of the temperature-adjustable four-probe square resistance test system, connect the host to the power supply, and preheat for 6 minutes;

[0047] Step 2: Estimate the resistivity of the sample to be tested at about 100,000, select K4 on the panel of the host as needed, and adjust K5 to "ρ" to measure the resistivity of the sample;

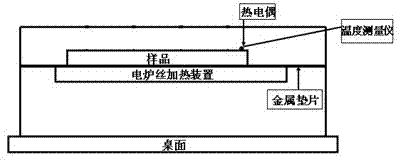

[0048] Step 3: Place the sample to be tested on the metal gasket of the base of the four-probe test platform, connect the thermocouple to the temperature tester, and make the thermocouple contact the surface of the sample to be tested, and then press down the four probes;

[0049] Step 4: Start the electric furnace wire heating device, adjust the heating rate, use a thermocouple and a temperature tester to measure the temperature of the sample to be tested as T1=30°C, T2=90°C;

[0050] Step 5: According to VO 2 The characteristics of the thermally induced ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Sheet resistance | aaaaa | aaaaa |

| Sheet resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com