Factory automation system and data synchronization method for same

A factory automation and data synchronization technology, which is applied in transmission systems, synchronization devices, digital transmission systems, etc., can solve the problems of data inconsistency, time waiting, errors, etc., to improve compatibility and processing efficiency, ensure authenticity and effectiveness, Avoid the effects of uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

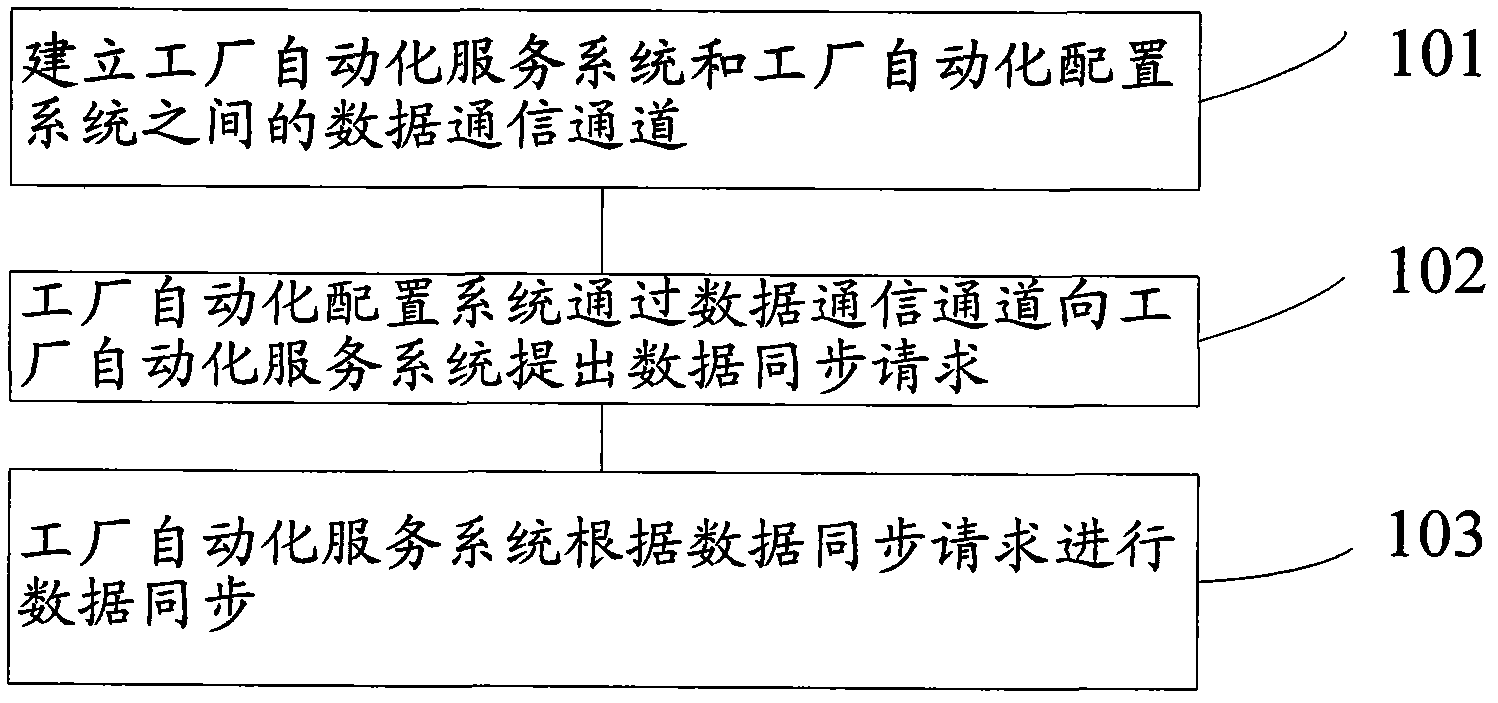

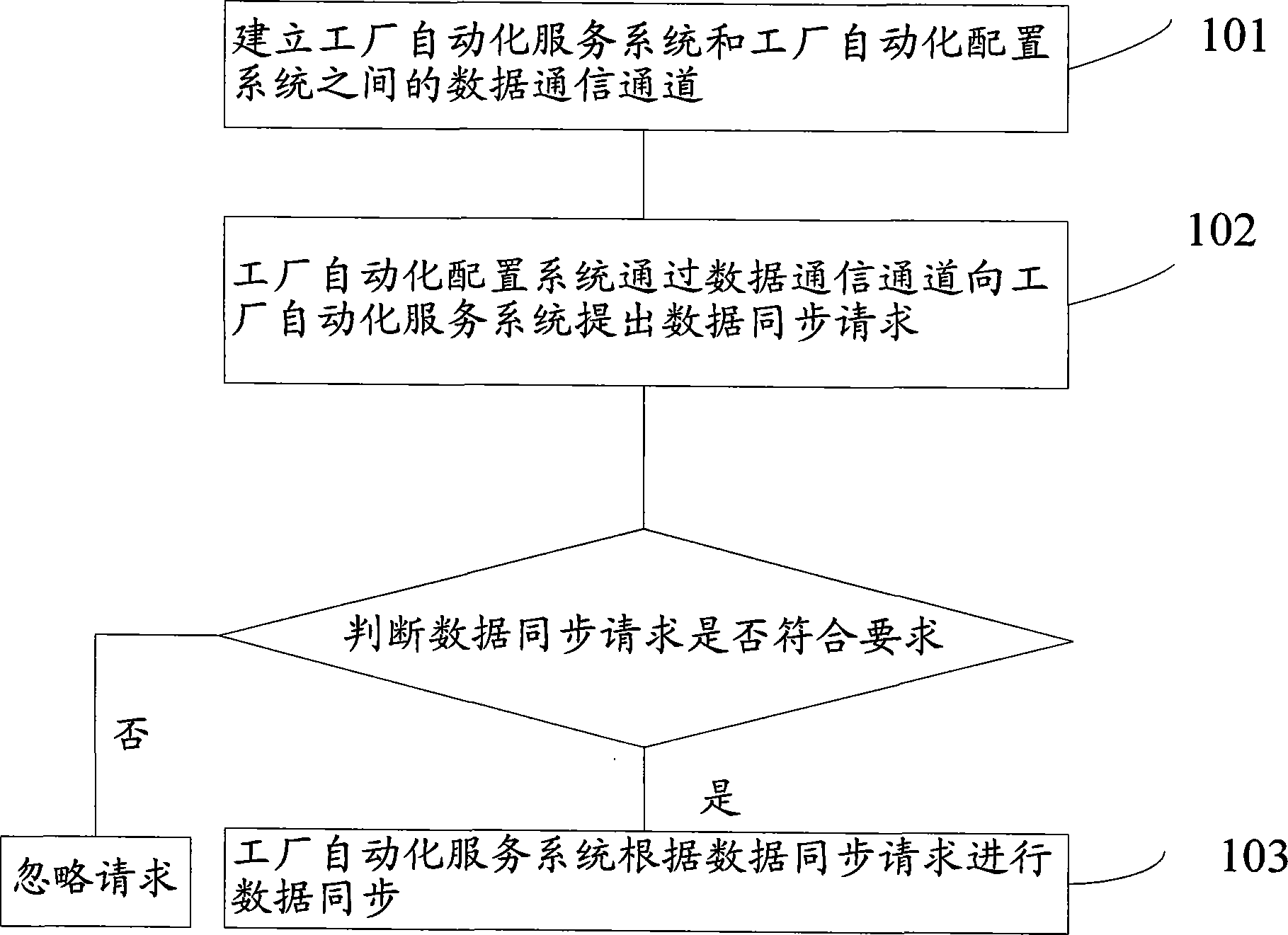

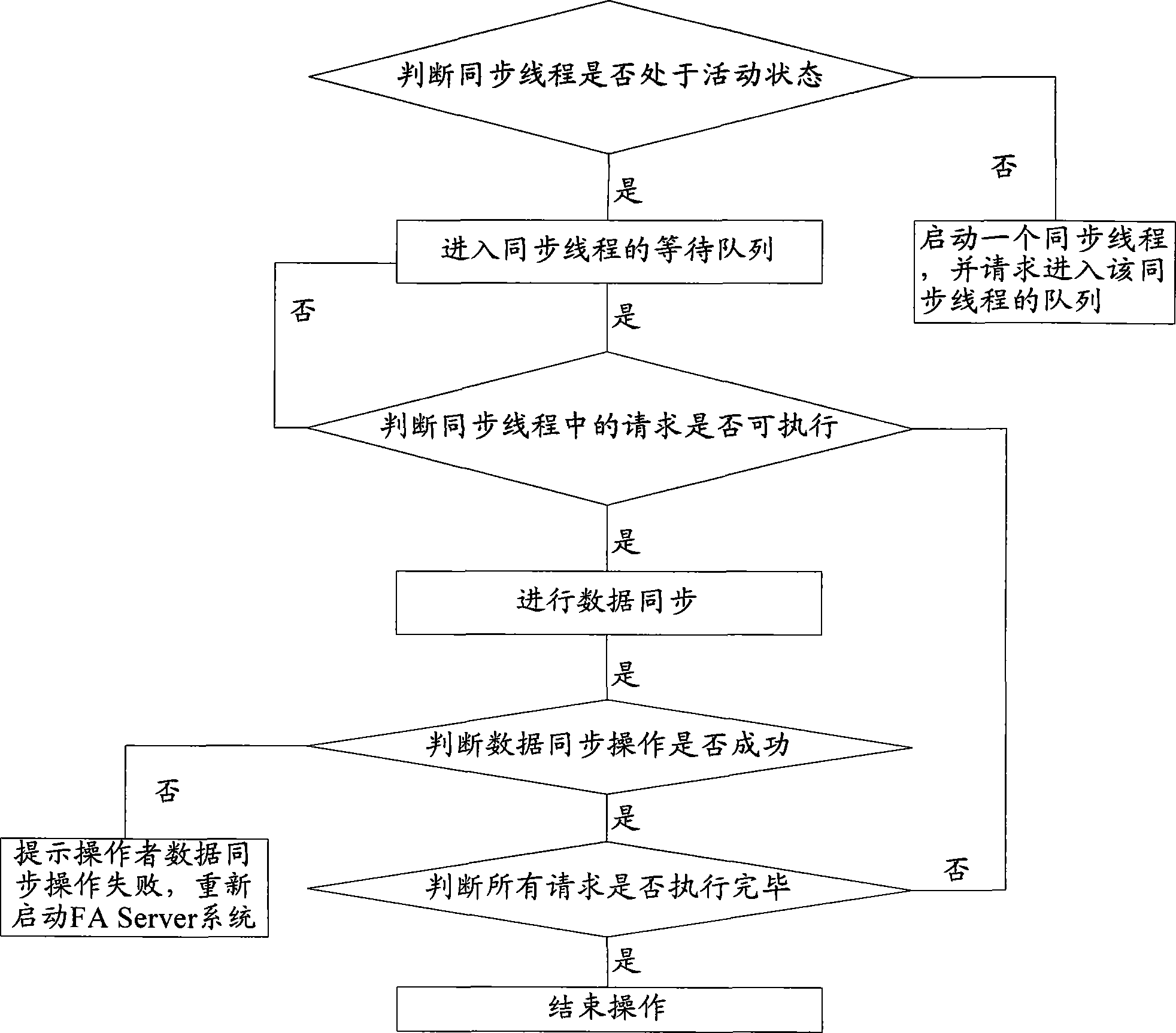

[0048] Please refer to figure 1 , showing Embodiment 1 of a data synchronization method for a factory automation system of the present invention, comprising the following steps:

[0049] Step 101, establishing a data communication channel between the FA Server system and the FA Config system.

[0050] The data communication channel here may be a channel for constantly synchronizing data between the FA Server system and the FA Config system, and is realized through data communication technologies such as named channels or Remoting (distributed processing) objects.

[0051] Step 102, the FA Config system sends a data synchronization request to the FA Server system through the data communication channel.

[0052] Step 103, the FA Server system performs data synchronization according to the data synchronization request.

[0053] After the operator saves the FA Config system, the FA Config system can submit a data synchronization request to the FA Server system through the data c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com