Full-automatic monitoring system of cutter suction dredger diesel engine set

A cutter suction dredger and diesel unit technology, applied in the direction of total factory control, total factory control, electrical program control, etc., can solve problems such as unsuitable for workers, unable to find equipment in time, and bad

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

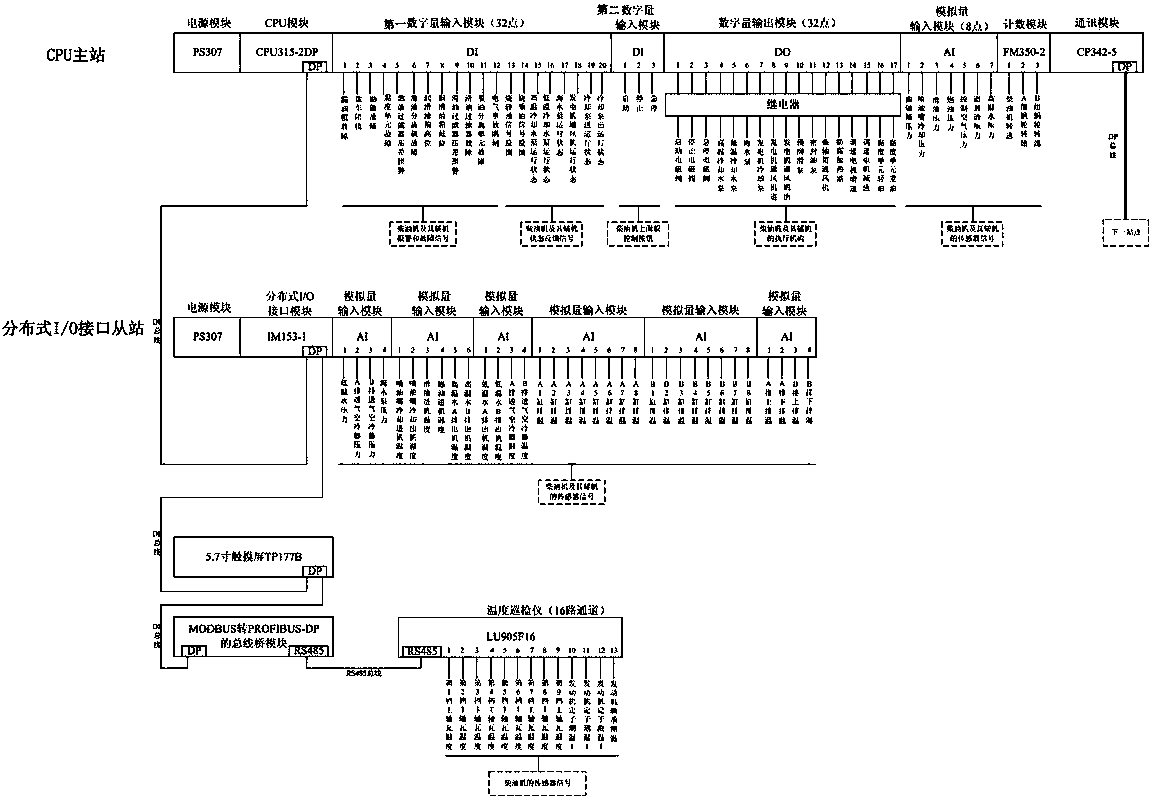

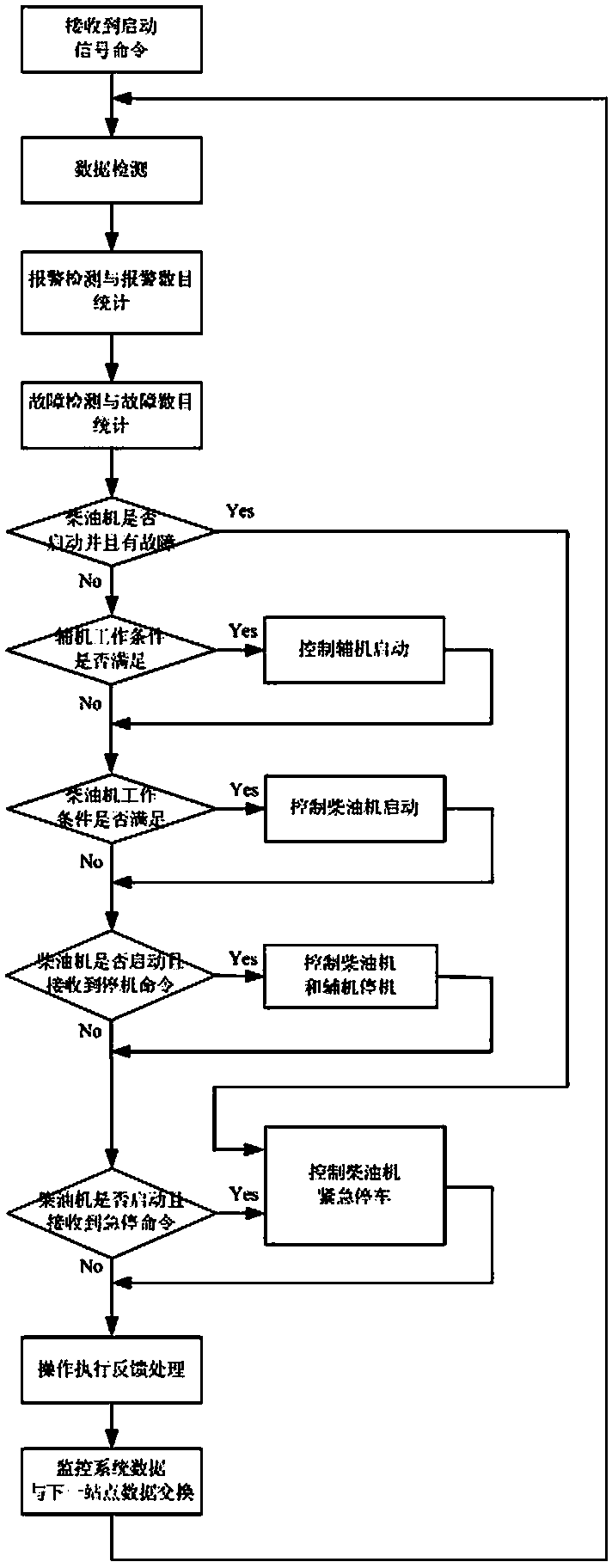

[0009] The fully automatic monitoring system for cutter suction dredger diesel units includes a PLC monitoring cabinet located in the control room and connected to the diesel engine and auxiliary machines in the engine room. The PLC monitoring cabinet consists of a CPU master station, a distributed I / O interface slave station, Touch screen, MODBUS to PROFIBUS-DP bus bridge module, and 16-channel temperature inspection instrument using MODBUS protocol communication; CPU master station includes master station power supply module using PROFIBUS-DP protocol communication, CPU module, used to detect diesel engines and auxiliary The first digital input module for the alarm, fault and state feedback signals of the engine, the second digital input module for detecting the operation signal on the panel of the diesel engine, and the digital output module for controlling the operation of the diesel engine and auxiliary machines through relays, used for The analog input module of the maste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com