Amorphous alloy plane stepped iron core and manufacturing method thereof

A technology of amorphous alloy and production method, which is applied in the manufacture of inductors/transformers/magnets, magnetic materials, magnetic objects, etc., can solve the problems of poor short-circuit resistance, many square coil materials, high excitation current and noise, etc. Small, material saving, small excitation current effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

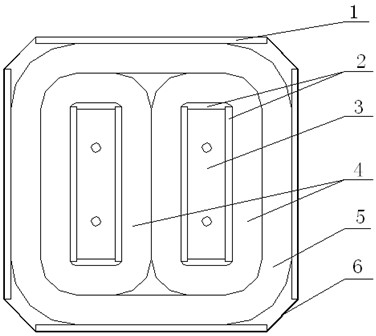

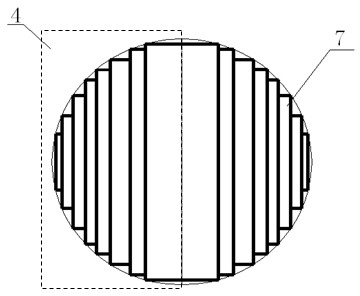

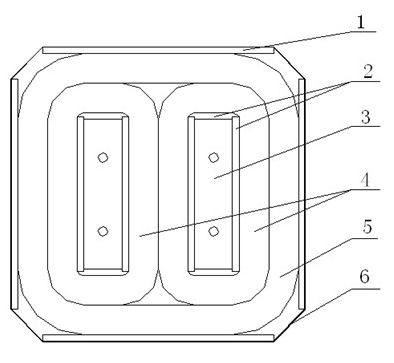

[0022] like figure 1 , figure 2 As shown, an amorphous alloy planar stepped iron core includes a formwork, a small iron core 4, a large iron core 5, and an inner mold mold 3. The formwork is divided into an outer formwork 1 and an inner formwork 2, and the large iron core 5 is located inside the outer formwork 1. There are two small iron cores 4 arranged side by side in the large iron core 5, and an inner formwork 2 is arranged in the middle of each small iron core 4. The inner formwork mold 3 is installed in the inner formwork 2, and the outer formwork 1 binds the entire amorphous iron core by binding the steel belt 6. Lashing into shape.

[0023] A method for manufacturing an amorphous alloy planar stepped iron core, comprising the following steps:

[0024] 1. Rolling: divide 5 pieces of amorphous tapes with specifications of 142mm, 170mm, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Specification | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com