Transformer copper pipe lead with internal cooling structure

An internal cooling and transformer technology, applied in the direction of transformer/inductor coil/winding/connection, transformer/inductor cooling, etc., can solve the problems of increasing the effective cross-sectional area of the copper tube, reducing the effective insulation distance, and increasing material consumption. , to save the amount of raw materials, reduce the cross-sectional area, and ensure the effect of temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

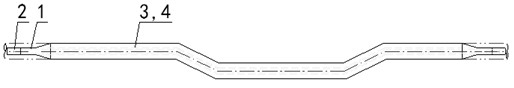

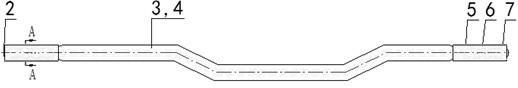

[0013] Accompanying drawing is a kind of specific embodiment of the present invention.

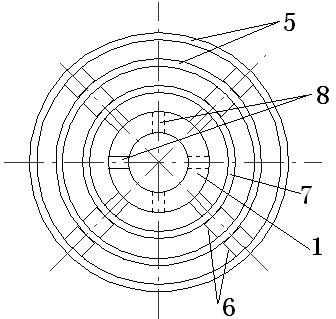

[0014] The transformer copper tube lead wire with internal cooling of the present invention includes lead joints 2 fixed at both ends of the copper tube lead wire 1, crepe paper 3 wrapped in the middle of the copper tube lead wire, the copper tube lead wire adopts an internal cooling structure, and the copper tube lead wire circulates To cool the oil flow, the two ends of the copper pipe lead are respectively provided with several oil inlet and outlet slots 8, and the two ends of the copper pipe lead and the outside of the lead joint are wrapped with binding tape 7 and crepe paper from the inside to the outside in sequence, and the crepe paper is covered with a number of A layer of insulating cylinder 5, a plurality of stays 6 are arranged between the crepe paper and the insulating cylinder, and between two adjacent layers of insulating cylinders.

[0015] Four oil inlet and outlet grooves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com