Die bonder

A die-bonding machine and die-bonding technology, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, circuits, etc., can solve the problems of difficulty in significantly increasing the operating frequency of the die-bonding head and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

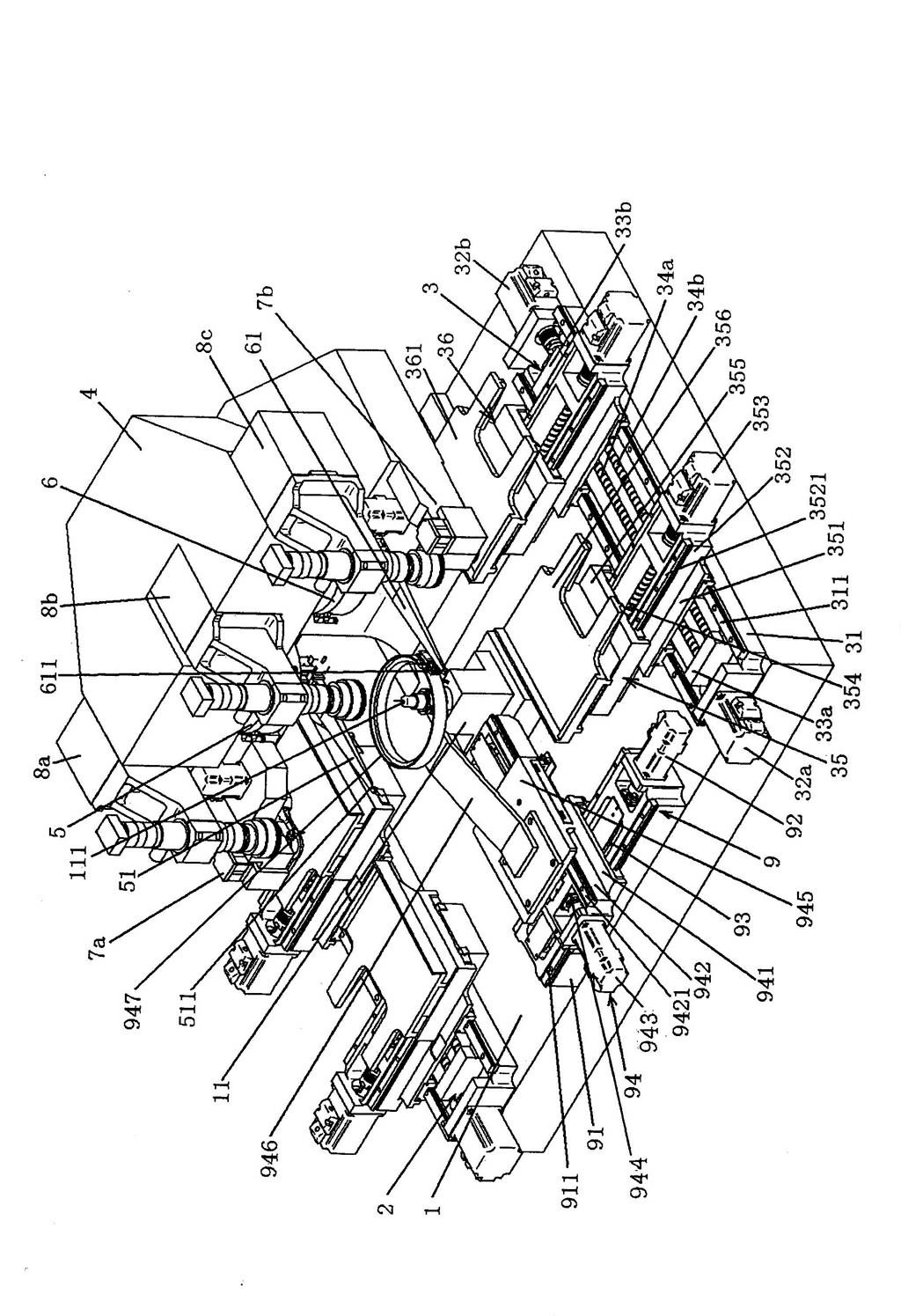

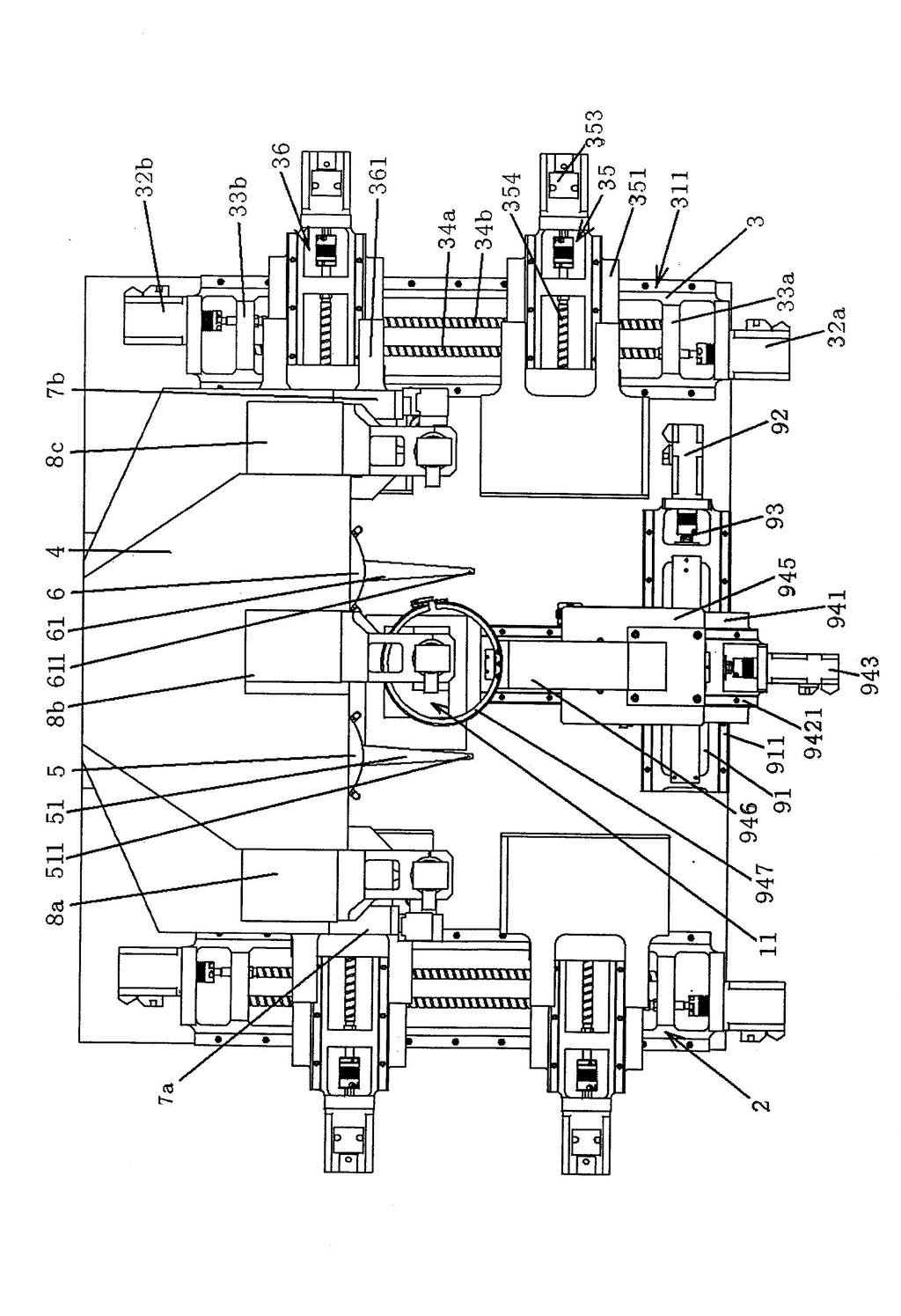

[0027] See Figure 1 to Figure 4 , a rectangular support platform 1 is provided, and a thimble mechanism 11 equipped with a thimble 111 is arranged at the central position of the support platform 1. The specific structure of the thimble mechanism 11 is preferably a cam structure to ensure the up and down of the thimble 111. vertical movement. at present figure 1 and figure 2 The position state shown is an example, a first die-bonding motion mechanism 2 is provided on the left side of the support platform 1, and a second crystal-bonding motion mechanism is provided on the right side and at a position corresponding to the first crystal-bonding motion mechanism 2 Mechanism 3, since the structures and working principles of the first and second crystal-bonding motion mechanisms 2 and 3 are the same, the applicant only elaborates on the second crystal-bonding motion mechanism 3 .

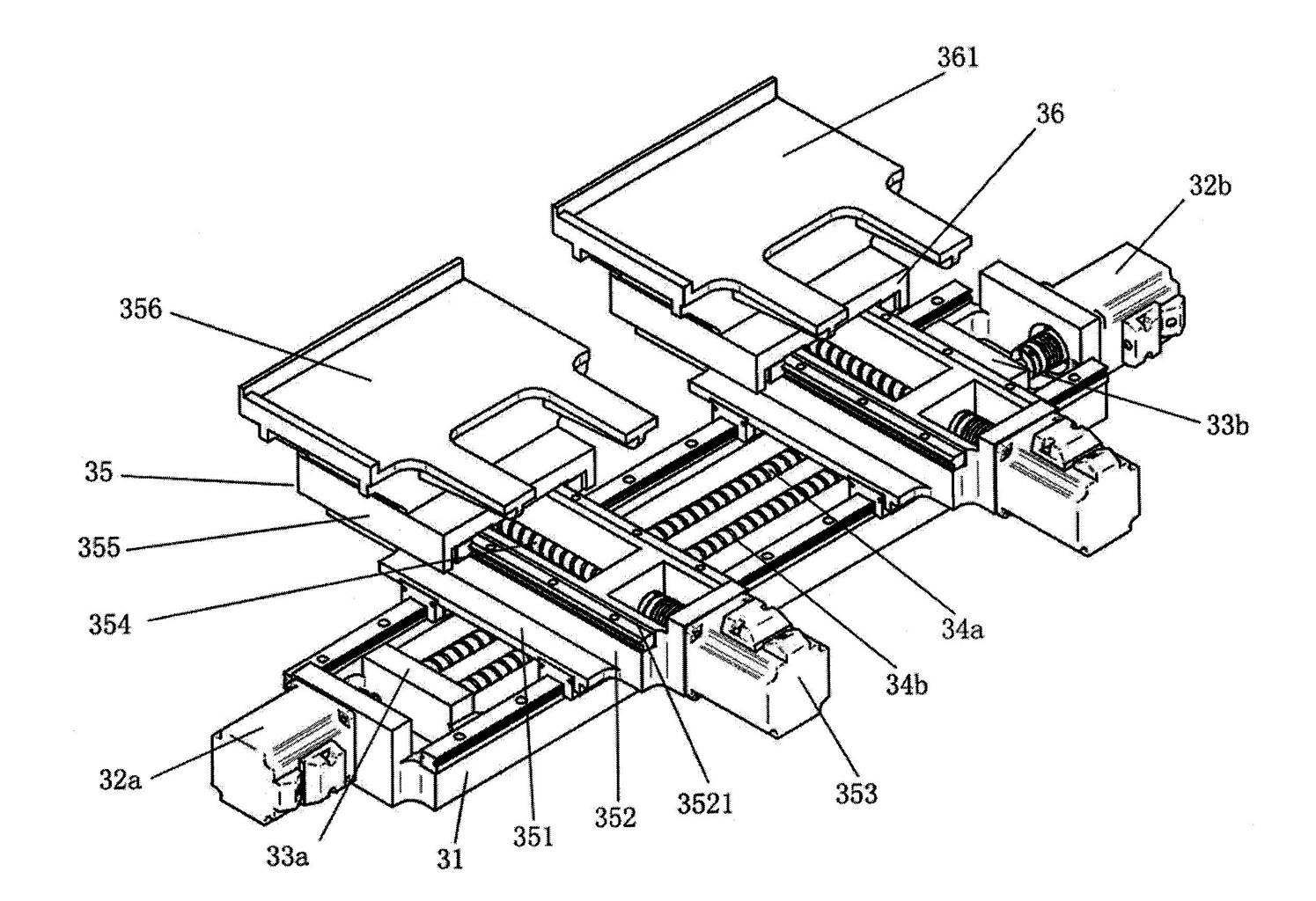

[0028] See the key points image 3 and combine figure 1 and figure 2 The preferred b...

Embodiment 2

[0041] please see Figure 6 and Figure 7 , only the first motor 32a on the first carrier moving device 35 and the second carrier moving device 36 of the second solid crystal moving mechanism 3, the second motor 32b, the first screw seat 33a, the second screw seat 33b, The first screw rod 34a, the second screw rod 34b use the first linear motor 37 with the first permanent magnet seat 371, the first permanent magnet 372 and the first coil 373 instead, and the third motor 353 and the third screw rod 354 are used instead The second linear motor 357 has a second permanent magnet seat 3571 , a second permanent magnet 3572 and a second coil 3573 , and the rest are the same as those described in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com