Ion-exchange device, column therefor, and water treatment device

A technology of ion exchange device and water treatment device, which is applied in the direction of ion exchange treatment device, ion exchange water/sewage treatment, ion exchange, etc., can solve the problems of water quality reduction, reduce height, manufacture cheaply, and improve economy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] Embodiment 1, comparative example 1

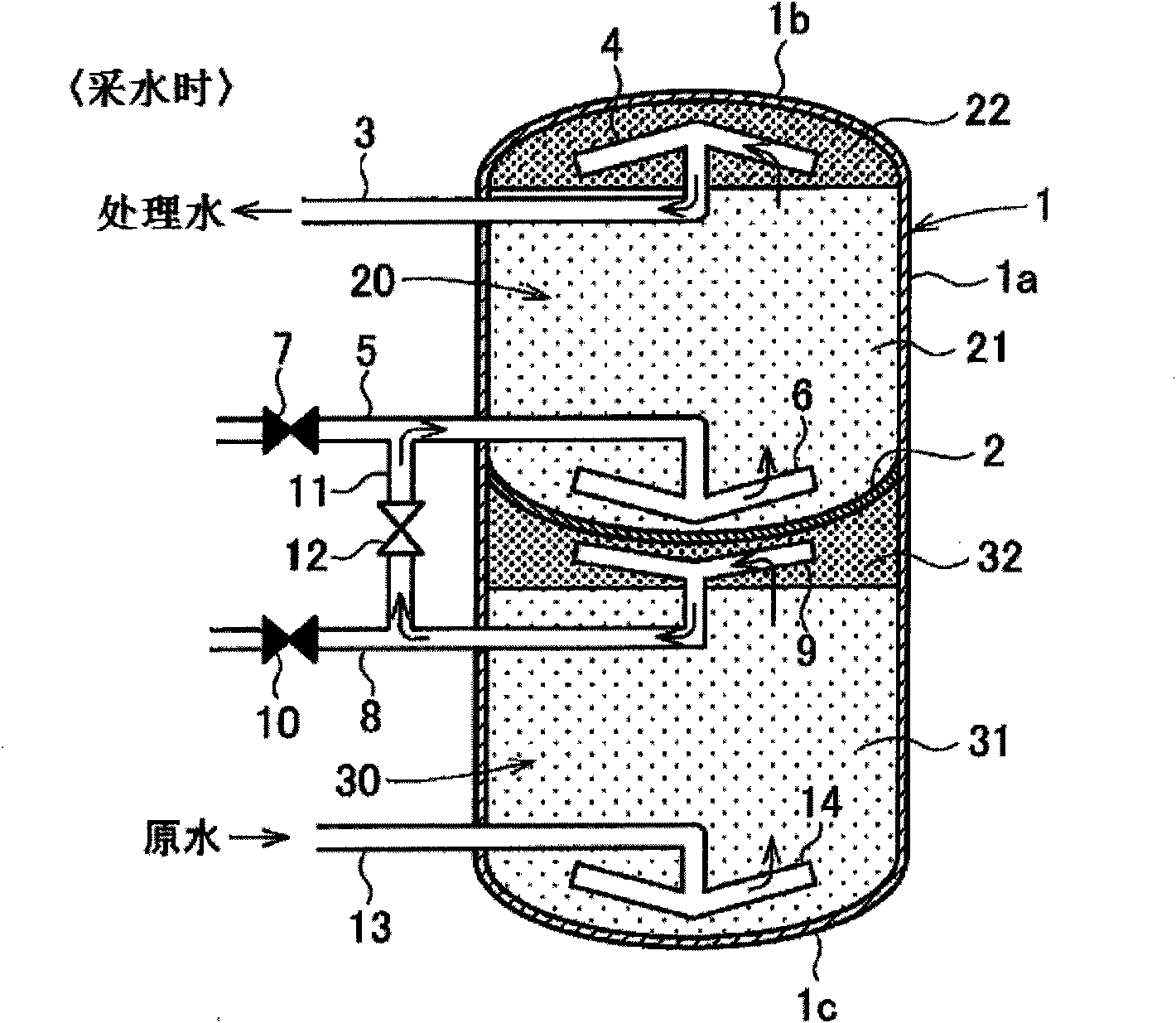

[0094] Used in Example 1 Figure 1a , 1b The ion exchange device shown. The specifications are as follows.

[0096] Tower height: 3000mm

[0097] Upper chamber volume: 190L

[0098] Lower chamber volume: 260L

[0099] Filling capacity of cation exchange resin 21: 150L

[0100] Filling capacity of anion exchange resin 31: 200L

[0101] Filling amount of non-reactive resin 22: 30L

[0102] Filling amount of non-reactive resin 32: 30L

[0103] In Comparative Example 1, a commercially available mixed-bed ion exchange device was used. The specifications are as follows.

[0105] Tower height: 4000mm

[0106] Volume: 640L

[0107] Filling capacity of cation exchange resin: 150L

[0108] Filling capacity of anion exchange resin: 200L

[0109] In Example 1 and Comparative Example 1, the following materials were used for the anion exchange resin and the cation exchan...

Embodiment 2

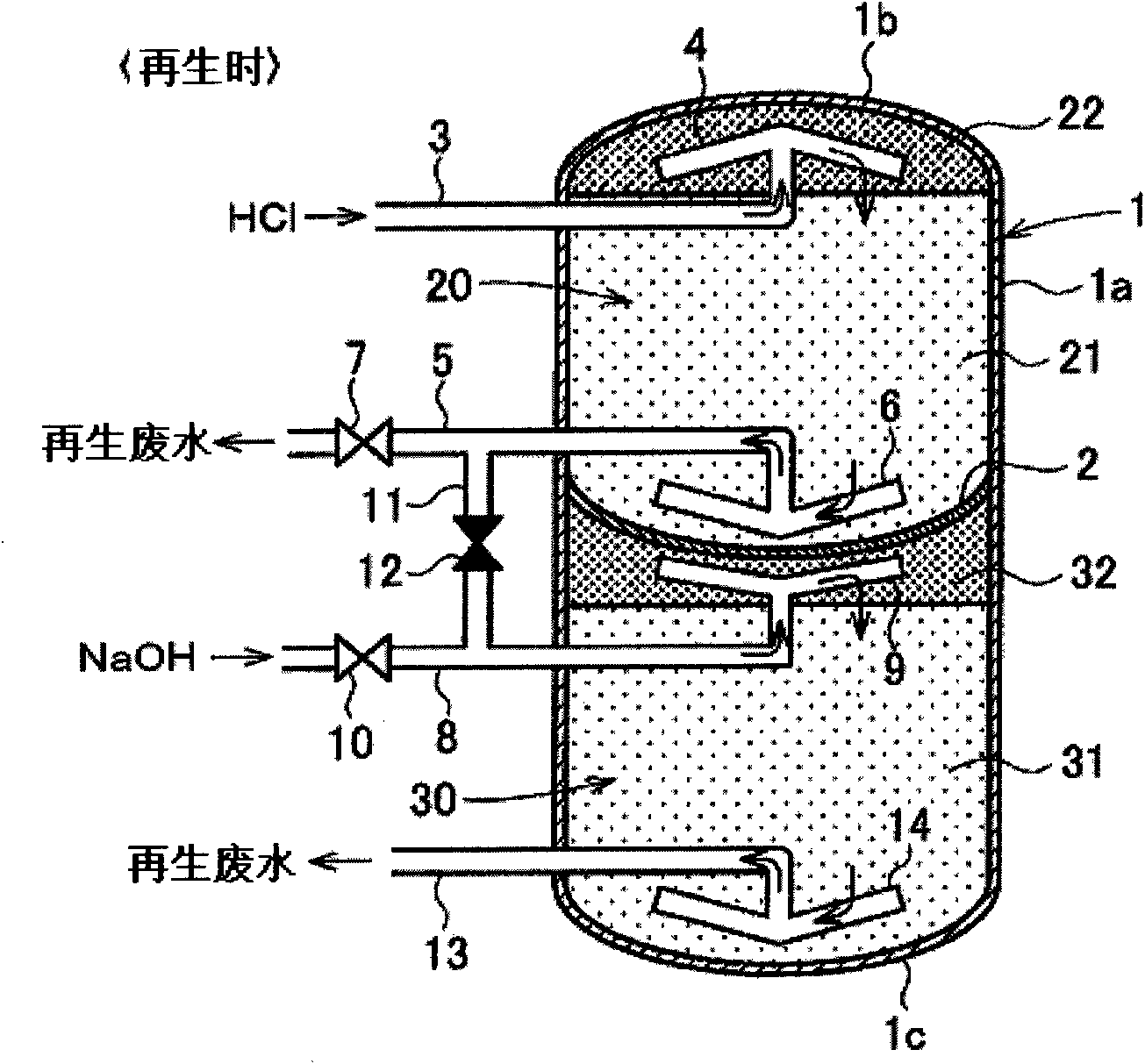

[0132] Pass the simulated raw water described later to the RO device as the hardness component removal equipment, and then pass the water to Figure 1a , 1b The ion exchange device shown. The main conditions of this ion exchange device are as follows.

[0133] (1) Ion exchange resin

[0134] Cation exchange resin: Dow 650C, filling volume 300mL

[0135] Anion exchange resin: Dow 550A, filling volume 600mL

[0136] (2) Water flow: 1L / min

[0137] (3) Regeneration conditions

[0138] The regeneration solution is as follows.

[0139] Aqueous HCl solution: HCl concentration 5% by weight, water flow rate: 1L / h, 30 minutes

[0140] NaOH aqueous solution: NaOH concentration 5% by weight, water flow rate: 2L / h, heating at 40°C for 30 minutes

[0141] The regenerating solution was passed as follows.

[0142] 30 minutes (drug flow time) → 30 minutes ultrapure water flow (drug extrusion time) → 15 minutes raw water flow (operation switching time)

[0143] (4) RO device

[0144]...

reference example 1

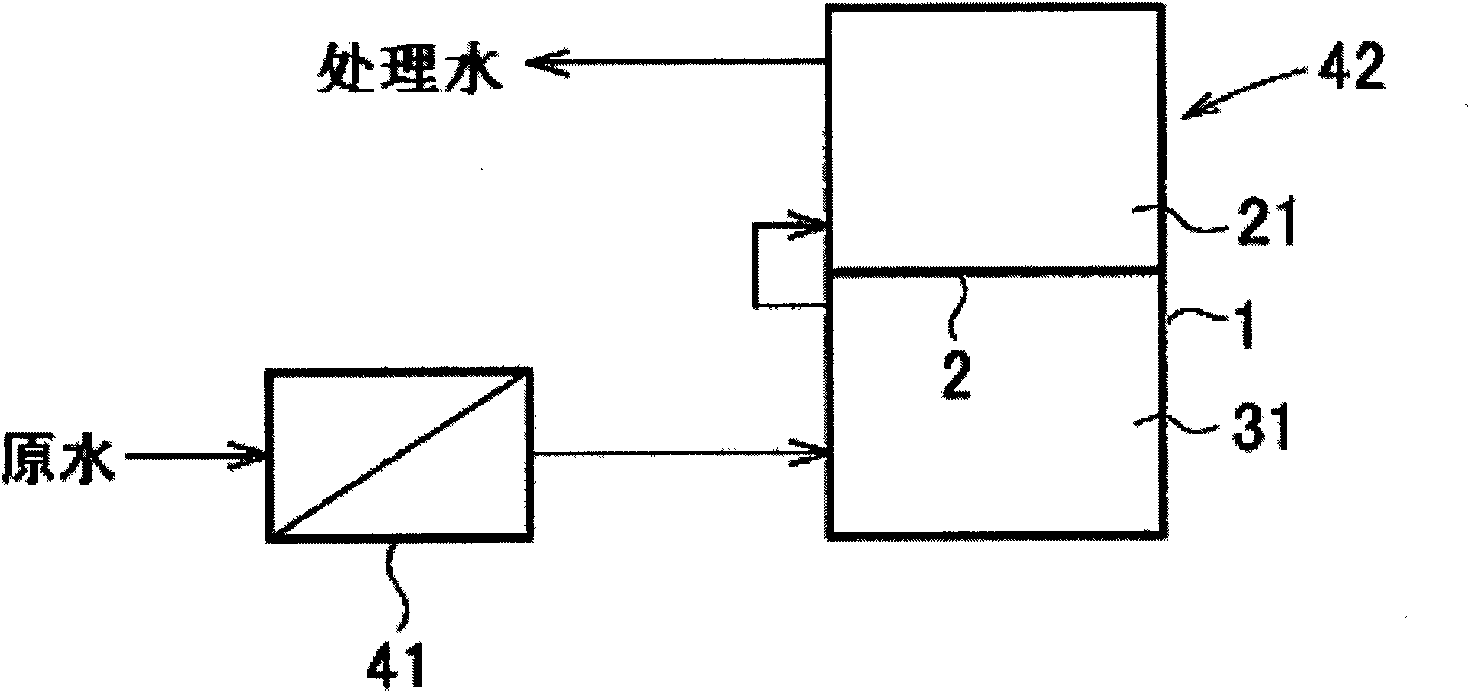

[0157] In Example 2, after passing the simulated raw water through the RO device, the water was first passed through the cation exchange resin, and then the water was passed through the anion exchange resin. That is, the order of passing water through the anion exchange resin and the cation exchange resin is reversed from Example 2. Other than that, water was passed in the same manner as in Example 2. As a result, as shown in Table 4, the Na concentration in the treated water after 1 hour (Hr) of water flow after regeneration was 3 ppt, which was confirmed to be a concentration several times higher than in Example 2. The Na concentration of the treated water between 360 hours after the start of water flow is shown in image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com