Degradable anti-clogging underground drip irrigation pipe and manufacturing method thereof

An underground drip irrigation and anti-clogging technology, which is applied in the direction of botany equipment and methods, applications, climate change adaptation, etc., can solve the problems of drip irrigation pipe degradation difficulties, degraded soil, white pollution, etc., to improve energy dissipation efficiency and prevent clogging Self-adaptive ability, eliminating the cause of clogging substance formation, enhancing the effect of anti-clogging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

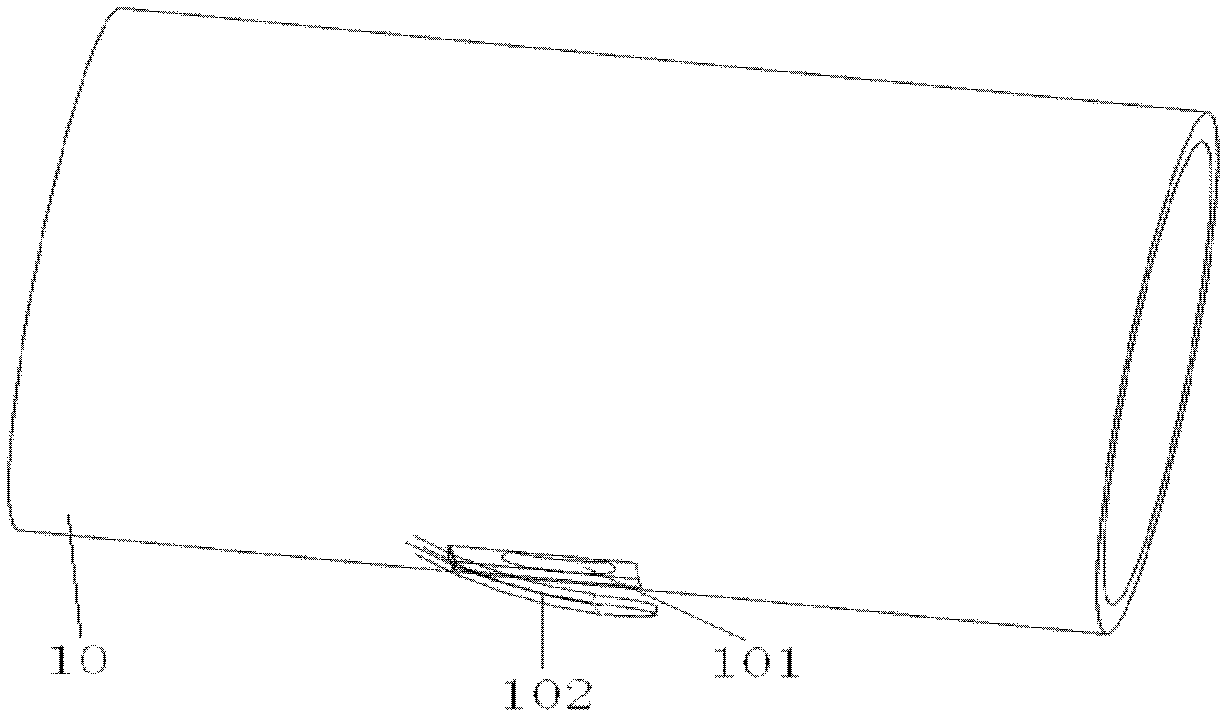

[0019] Such as figure 1 , figure 2 As shown, the present invention includes a drip irrigation pipe 10, and a plurality of emitters 20 are arranged at intervals on the inner wall of the drip irrigation pipe 10. A drip irrigation port 101 is provided on the drip irrigation pipe 10 corresponding to the water outlet of the emitter 20 , and a tongue 102 is provided on the drip irrigation port 101 .

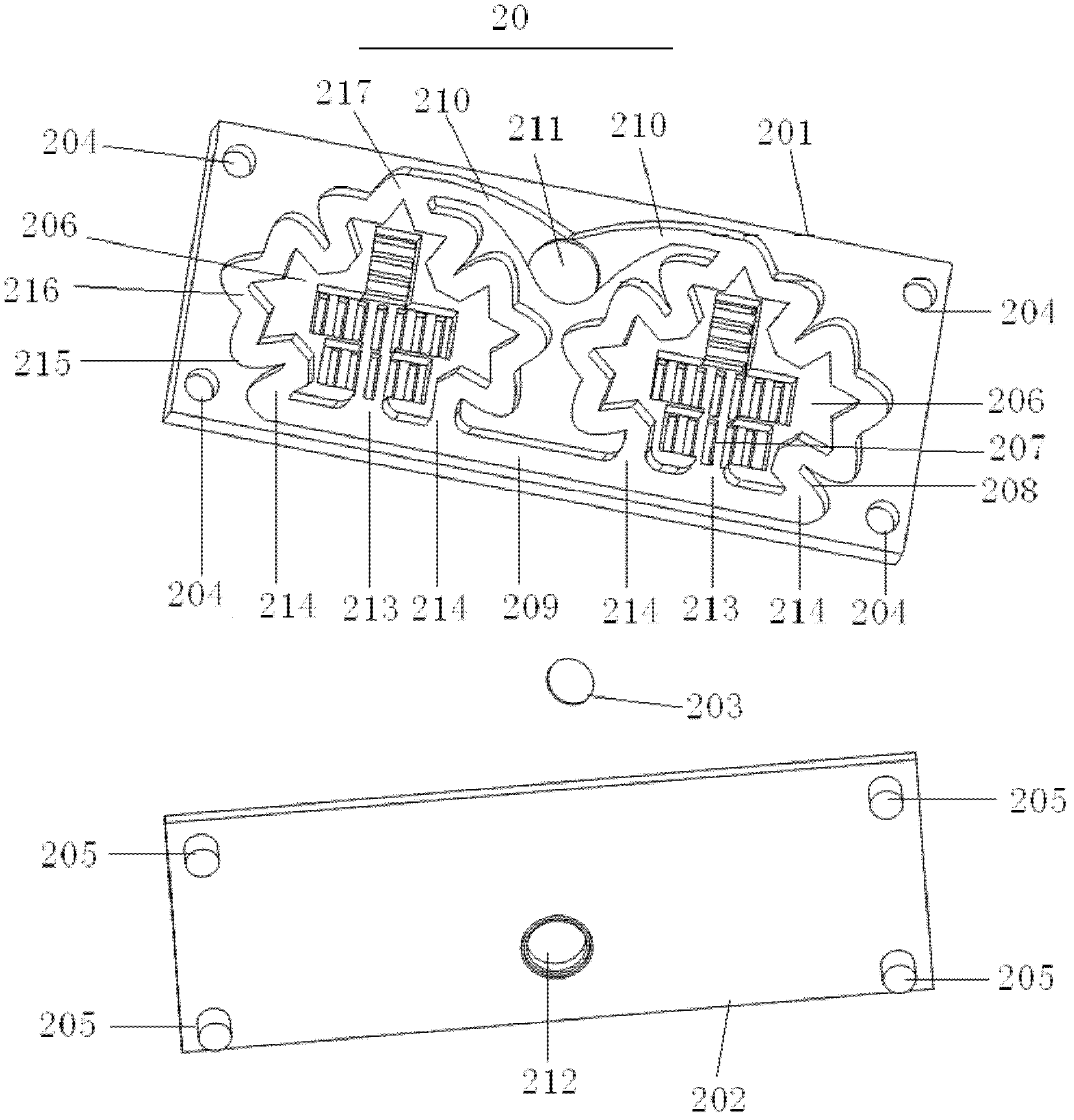

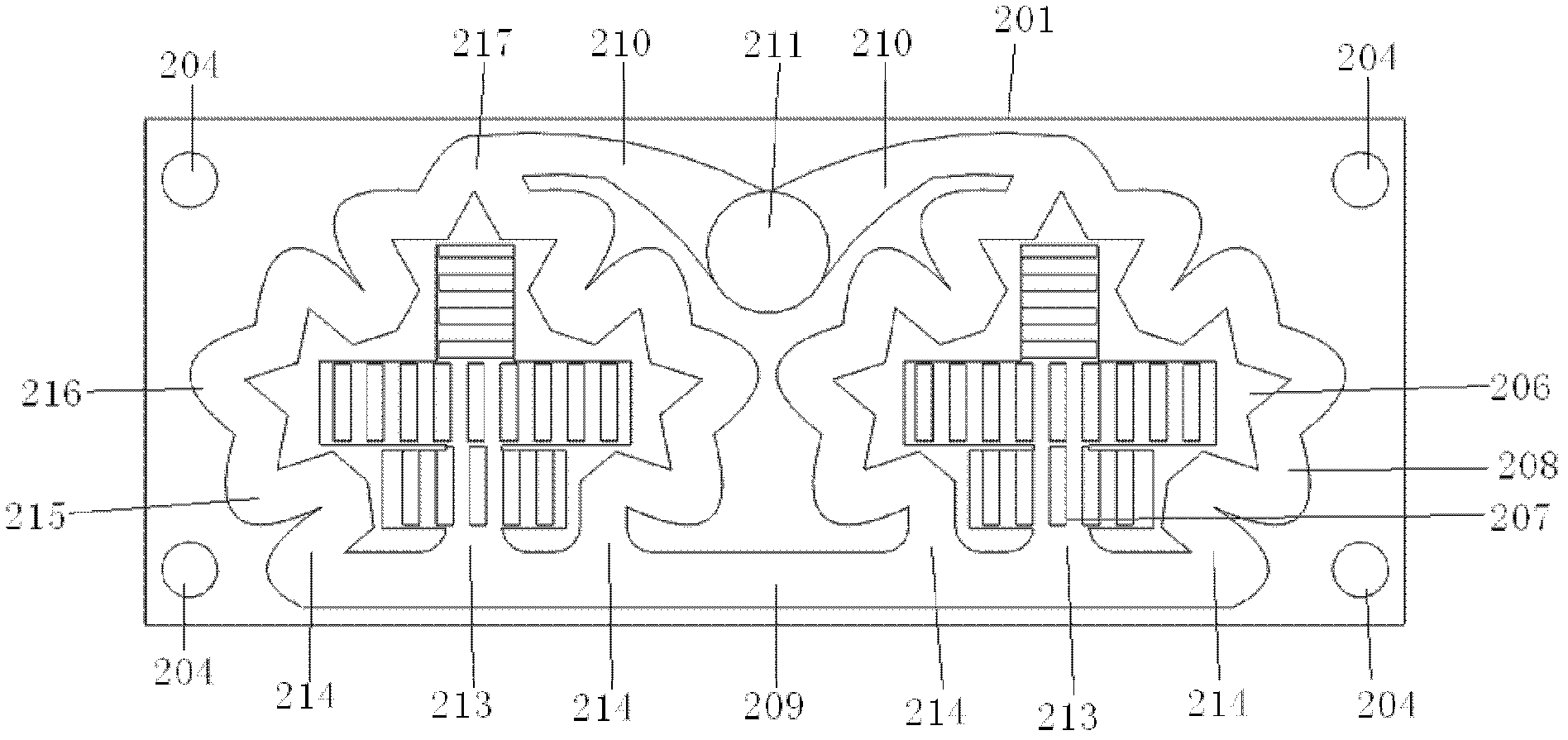

[0020] Such as figure 2 As shown, the emitter 20 is a cuboid structure, which includes a rectangular emitter upper piece 201 , a rectangular emitter lower piece 202 and a circular pressure compensation piece 203 . The four corners of the bottom surface of the upper emitter plate 201 are provided with a circular groove 204, and the four corners of the top surface of the emitter lower plate 202 are all provided with a cylindrical volume corresponding to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com