Functional milk cow feed additive capable of resisting heat stress and improving milk quality

A feed additive and anti-heat stress technology, applied in animal feed, animal feed, application, etc., can solve the problems of decreased immunity and increased disease susceptibility of dairy cows, so as to relieve low immunity, alleviate heat stress, and enhance The effect of regulating the function of the gastrointestinal tract

Active Publication Date: 2012-07-11

INNER MONGOLIA YOURAN ANIMAL HUSBANDRY CO LTD

View PDF6 Cites 21 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0021] Table 1

[0022]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to the field of feed additives, in particular to a functional milk cow feed additive capable of resisting heat stress and improving milk quality. The functional milk cow feed additive capable of resisting heat stress and improving milk quality contains the following raw materials by mass percent: 91-94 percent of yeast cultures, 5-8 percent of organic selenium, 0.5-1 percent of organic chromium and 0.1-0.3 percent of vitamin E. Since organic trace elements such as selenium AF and biological chromium which are produced through an amino acid chelation technique and the like are added into the feed additive, the problem of low absorbing and utilization ratio of the organic trace elements which are absorbed and utilized by milk cows is effectively solved. The problem of low immunity caused by heat stress is relieved, the occurrence probability of susceptible diseases such as mammitis is reduced, the digestion and utilization ratio of a feed is enhanced, the production performance is ensured to be fully exerted, and since several additives take a synergistic effect to the milk cows which are at the period of summer heat stress, the heat stress is effectively relieved by improving the body immunity and adjusting the gastrointestinal tract function.

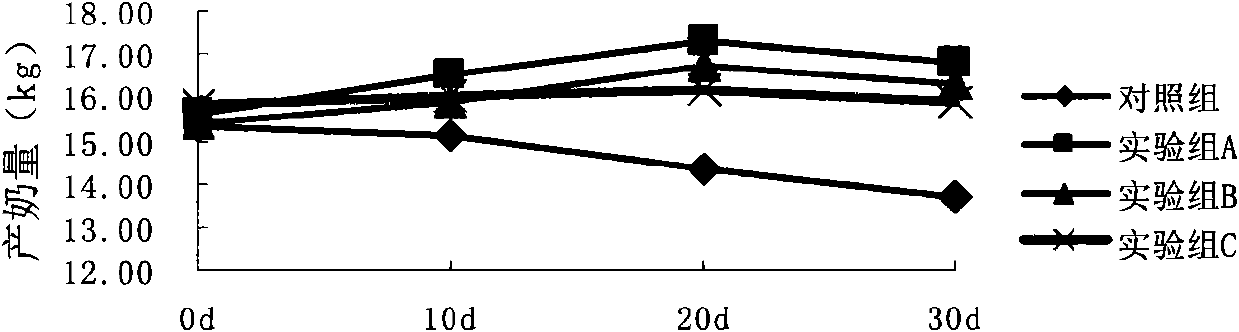

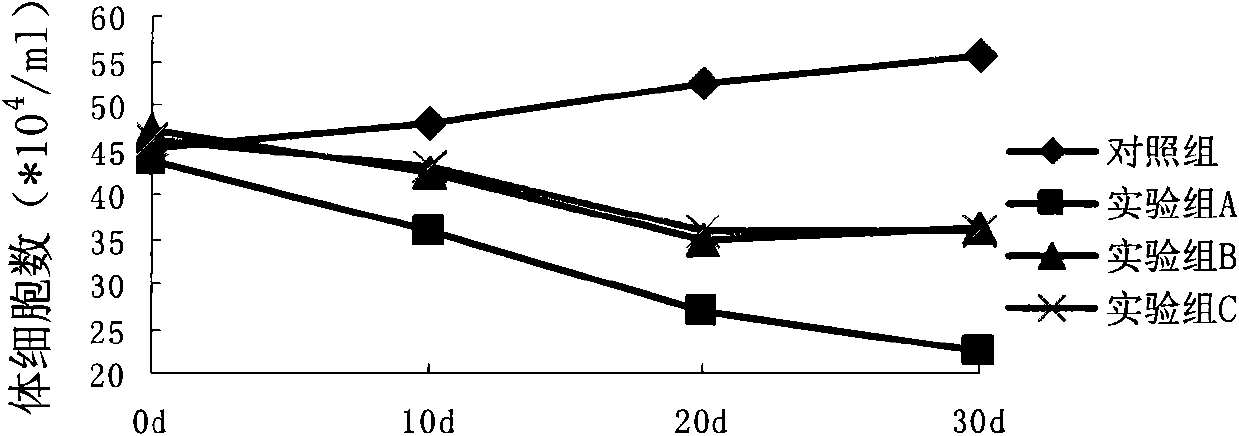

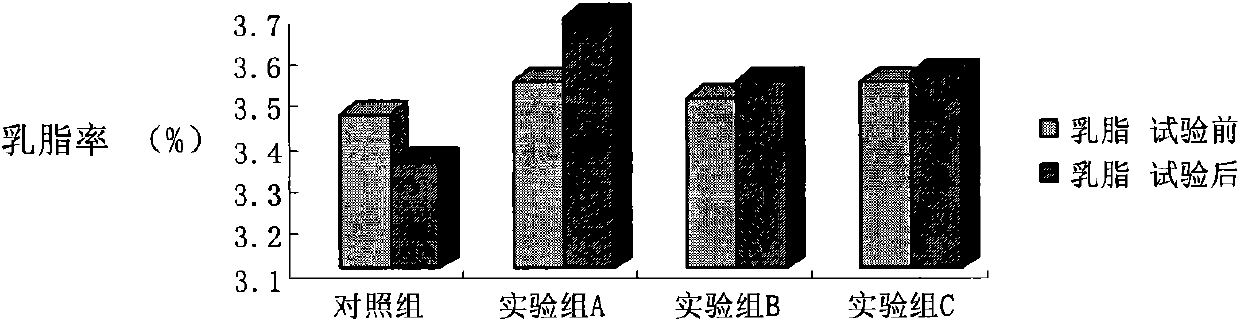

Description

technical field [0001] The invention relates to the field of feed additives, in particular, the invention relates to a functional feed additive for dairy cattle that resists heat stress and improves milk quality. Background technique [0002] Dairy cows require the most suitable external ambient temperature to be 5-25°C. When the temperature exceeds 28°C, the cows will have obvious heat stress response. In the hot summer, the external temperature is above 30°C for up to 3 months as long as. In this high-temperature environment, due to the slow perspiration rate of dairy cows, dairy cows show faster breathing, higher body temperature, reduced heat dissipation, decreased appetite, increased maintenance energy requirements, slowed rumen and intestinal peristalsis, reduced rumination time, and visceral blood. Reduced flow, reduced milk production, physiological and metabolic disorders, simultaneous decline in milk production and milk fat percentage, reduced reproductive rate, i...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): A23K1/18A23K1/16

Inventor 宋丽华杨明杨帆韩吉雨孙晓智岳丽莎耿跃

Owner INNER MONGOLIA YOURAN ANIMAL HUSBANDRY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com