Melting and washing screening method for kitchen waste treatment system

A kitchen waste and treatment system technology, applied in the field of solid waste disposal, can solve the problems of reducing the treatment effect, unfavorable for the recovery of organic materials, and unfavorable for the collection of organic components, achieving high overall utilization rate, improving oil concentration and Effectiveness of Operational Efficiency, Guaranteed Effectiveness and Safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

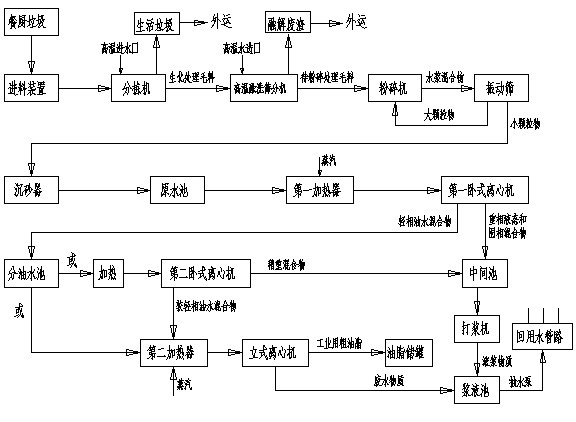

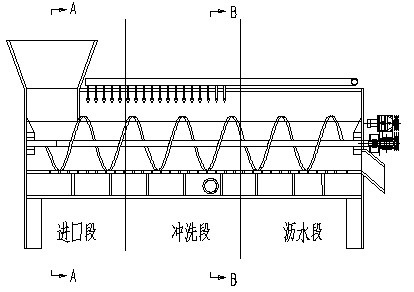

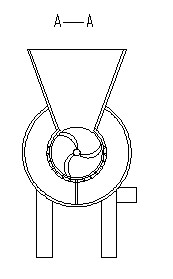

[0037] Such as figure 1 , figure 2 , Figure 2a , Figure 2b , image 3 , Figure 3a , Figure 3b As shown, the melting and washing screening method of the food waste treatment system, the food waste treatment system includes a sorter, a high temperature melting and washing screening machine, a pulverizer, a vibrating screen, a horizontal centrifuge, a beater, a vertical centrifuge Machine and slurry tank, the sorter inlet is equipped with a feeding device; the melting and screening method includes the following steps:

[0038] Conveying and feeding step: the food waste raw material is connected to the entrance of the feeding device, and the feeding device is activated to transport the food waste raw material to the entrance of the sorting machine;

[0039] Sorting and cleaning steps: a spray device is installed above the inner cavity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com