Non-steady state continuous casting process capable of damaging small steel ingot structure

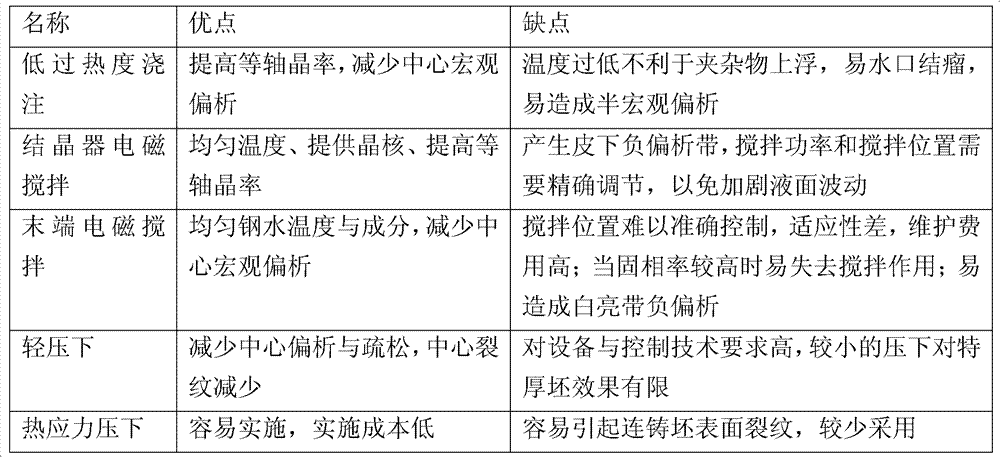

A continuous casting process, unsteady state technology, applied in unsteady state continuous casting process, billet billet and thick slab continuous casting production field, can solve the problem of destroying the structure of small steel ingots, to improve the purity of molten steel, avoid The effect of surface cracks and internal cracks, promoting the flow of molten steel and the floating of inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiments of the present invention are described in detail below in conjunction with the examples, but the specific embodiments of the present invention are not limited to the examples.

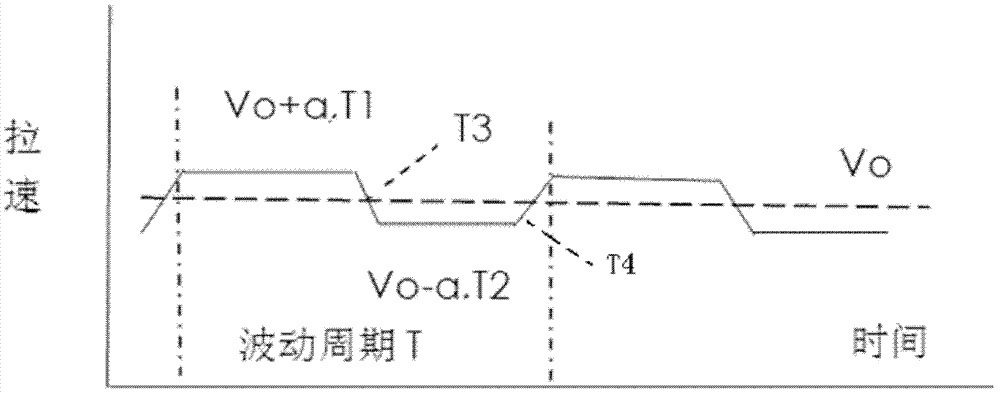

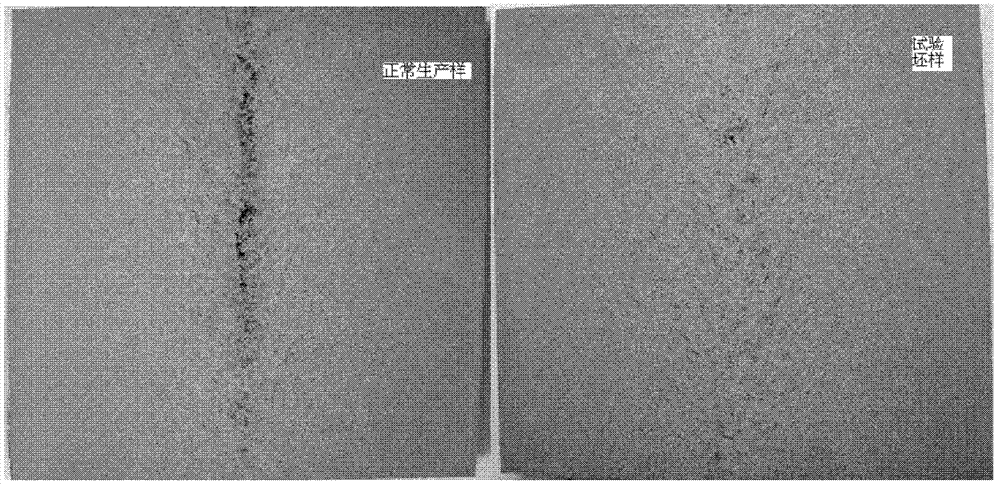

[0027] The implementation comparison was carried out on a six-machine six-strand billet continuous casting machine in a domestic special steel plant. The section of the continuous casting machine is 150mm×150mm, and the test steel type is 55#. The superheating degree of the whole furnace steel in the test furnace is 20-24°C (during the test period, the temperature of the tundish was measured 4 times with thermocouples, and the superheating degrees were 24°C, 23°C, 21°C, and 20°C), and the first half of the furnace was drawn at 2.1m / min. The casting speed is normal, the second half of the furnace test, the casting speed is 2.2 / 2.0m / min, adjusted every four minutes, each casting speed is 2 minutes, the down and up times are 3 seconds, the molten steel level of the crystalli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com