Robot claw

A technology of robots and grippers, applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve the problems of overloading, detachment, and bulkiness of retrieving materials, and achieve the effects of good use effect, light use weight and extended life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

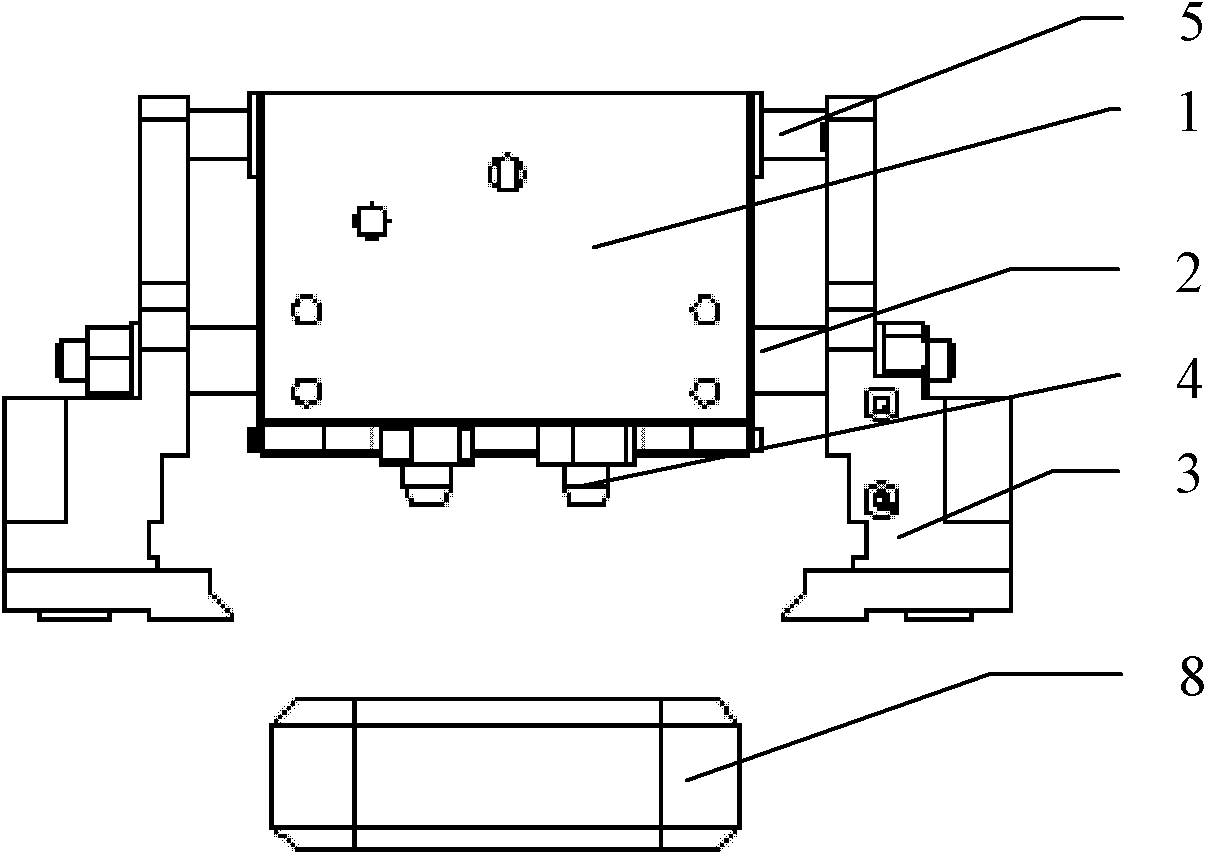

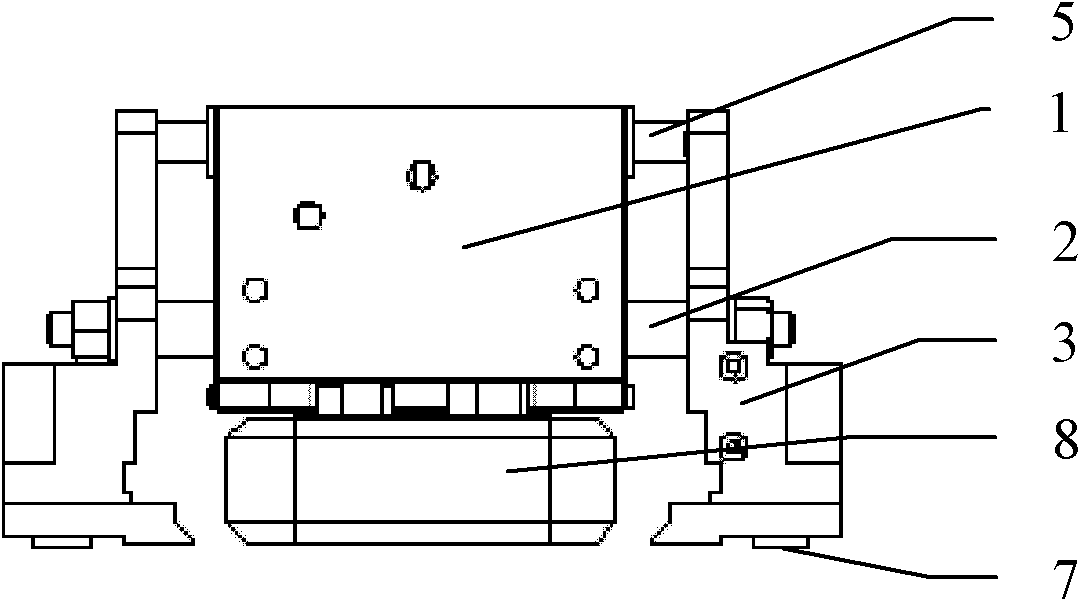

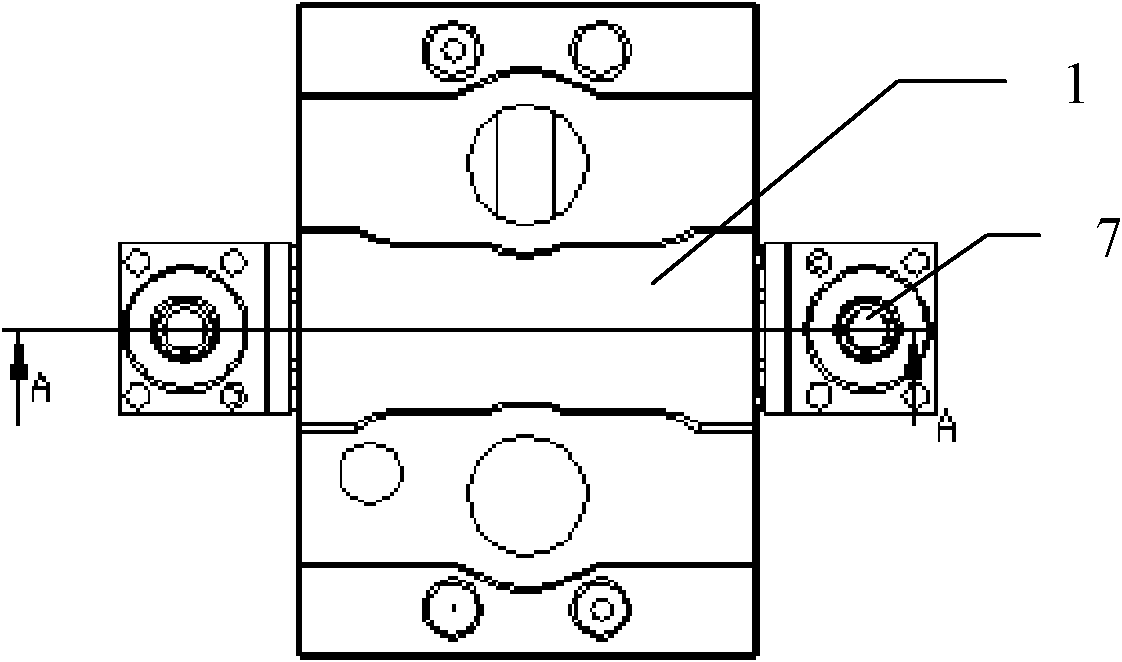

[0019] As an embodiment of the robotic gripper of the present invention, see Figure 1 to Figure 5 , comprising a cylinder block 1, a two-way cylinder, positioning pins 4 and grabbing nippers 3, the two-way cylinder is arranged on the cylinder block 1, a main shaft piston 2 is respectively provided at both ends of the two-way cylinder, and the grabbing nippers 3 Set on the main shaft piston 2, the positioning pin 4 is set on the lower surface of the cylinder block 1, the grasping nipper 3 is provided with a propping mechanism 7, and the propping mechanism 7 includes a propping cylinder 71 and a propping Raise the rod 72, and the described prop up rod 72 is arranged on the prop up cylinder 71.

[0020] The specific operation process of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com