Production process of forming stereo relief effect on packaging printing paper base

A three-dimensional embossing and production process technology, which is applied in the post-processing of printing, printing, printing devices, etc., can solve the problems of ink fluidity deterioration, increased labor costs, and insufficient transfer volume, so as to achieve no solvent volatilization and improve production efficiency , the effect of increasing the amount of transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

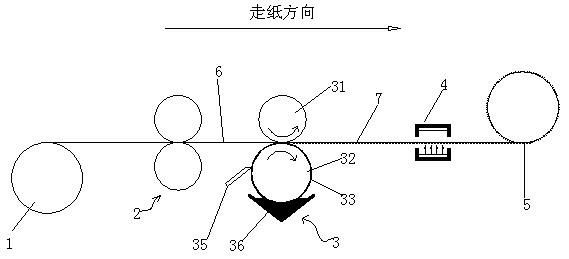

[0016] The production process of embossed effect on Huangguoshu cigarette label packaging paper includes the following steps in sequence:

[0017] (1) Load the roll white cardboard to be printed on the uncoiling device 1 of the multi-color rotogravure printing machine;

[0018] (2) After installing the printing plates of each color group of the graphic printing device, introduce the white cardboard into the graphic printing device 2 for graphic printing;

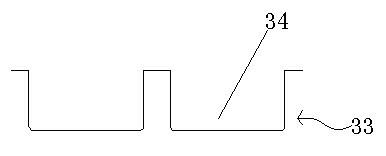

[0019] (3) The paper base 6 printed with graphics and texts is introduced into the UV embossing gravure printing working device 3 for overprinting UV embossing. The UV embossing gravure printing device includes an embossing roller 31 on the top, a The gravure plate roll 32, the gravure graphic part 33 of the plate roll is composed of a cell 34 engraved with a depth of 60 μm and an opening width of 125 μm by laser engraving according to the design requirements. The profile of the cell is U-shaped. The shape of the opening is...

Embodiment 2

[0023] The production process of the embossed effect of the packaging paper base of the Meijiajing toothpaste box includes the following steps in turn:

[0024] (1) Load the roll white cardboard to be printed on the uncoiling device 1 of the multi-color rotogravure printing machine;

[0025] (2) After installing the printing plates of each color group of the graphic printing device, introduce the white cardboard into the graphic printing device 2 for graphic printing;

[0026] (3) Introduce the paper base printed with graphics and text into the UV embossing and gravure printing working device 3 for overprinting UV embossing. The printing plate roller 32 and the gravure graphic part 33 of the plate roller are composed of cells 34 engraved with a depth of 65 μm and an opening width of 130 μm by laser engraving according to the design requirements. The cell section is U-shaped, and the cell opening is The shape is a regular hexagon, the screen line number of the cell is 75 l / cm,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com