Conveyer system

A transmission system and shell technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of easy adhesion between idlers and conveyor belts, deterioration of production environment, difficult maintenance and lubrication, etc., so as to prevent dust from flying , Solve the effect of being easily corroded and bonded

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

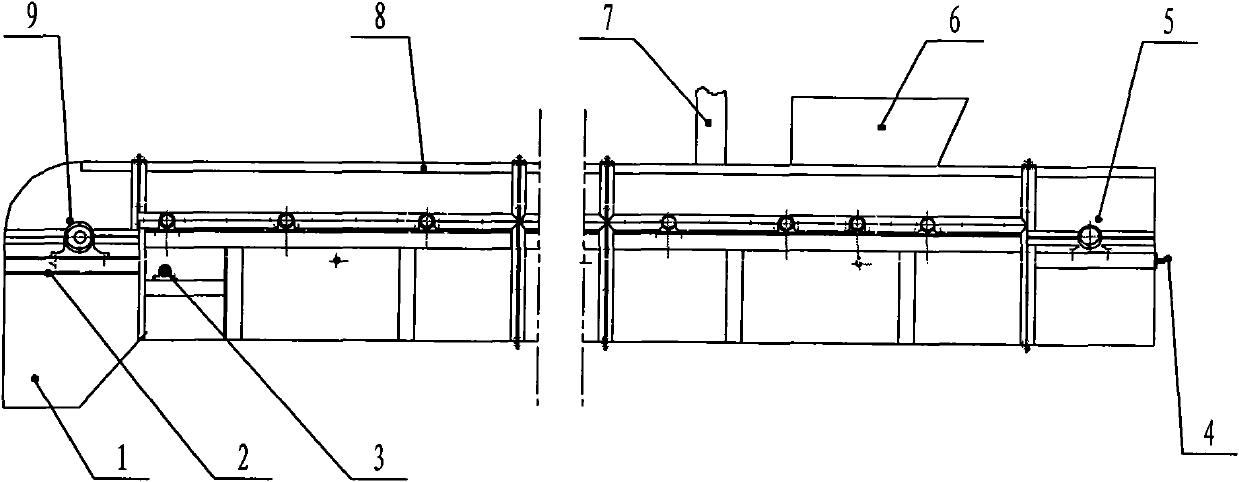

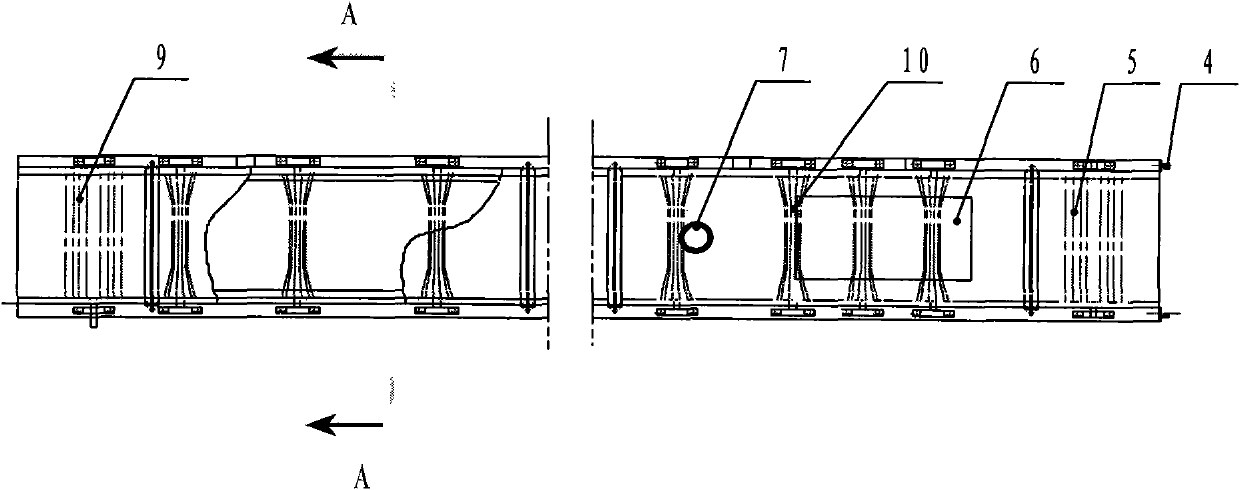

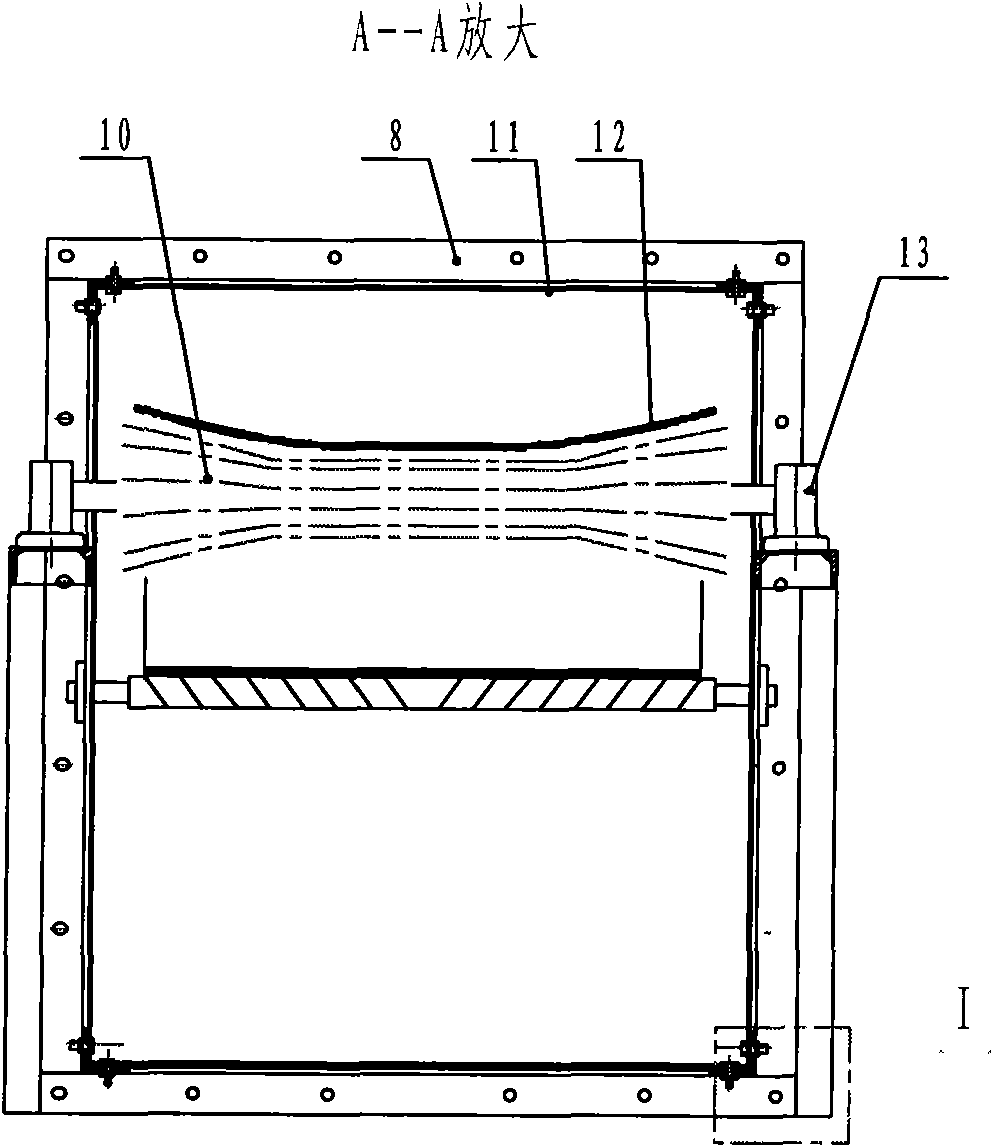

[0012] The transmission system of the present invention will be further described below in conjunction with the accompanying drawings. A transmission system, including a sealed casing 8, a material inlet 6, a material outlet 1, a driving wheel 9, a driven wheel 5, a reversing wheel 3, an air outlet 7, a conveyor belt 12, a scraper 2, and a dumbbell basket Type idler roller 10, idler bearing housing 13, and adjustment lead screw 4, the idler bearing housing is installed outside the sealed housing; the inside of the sealed housing is provided with an anti-adhesion layer 11 and On the sealed housing 8, the anti-adhesion layer is made of anti-adhesion material.

[0013] When using the conveying system of the present invention, the exhaust port 7 is connected to the exhaust fan, and a negative pressure is formed in the sealed casing 8; the driving wheel 9 is driven by external power and rotates in the counterclockwise direction, and the driving wheel drives the conveyor belt to mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com