A kind of super absorbent resin and its preparation method and application

A super absorbent resin, super absorbent technology, used in absorbent pads, sanitary napkins, bandages, etc., can solve the problems of high reactivity, reduced yield, structural damage, etc., to increase specific surface area, improve gel strength. , Improve the effect of water absorption speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

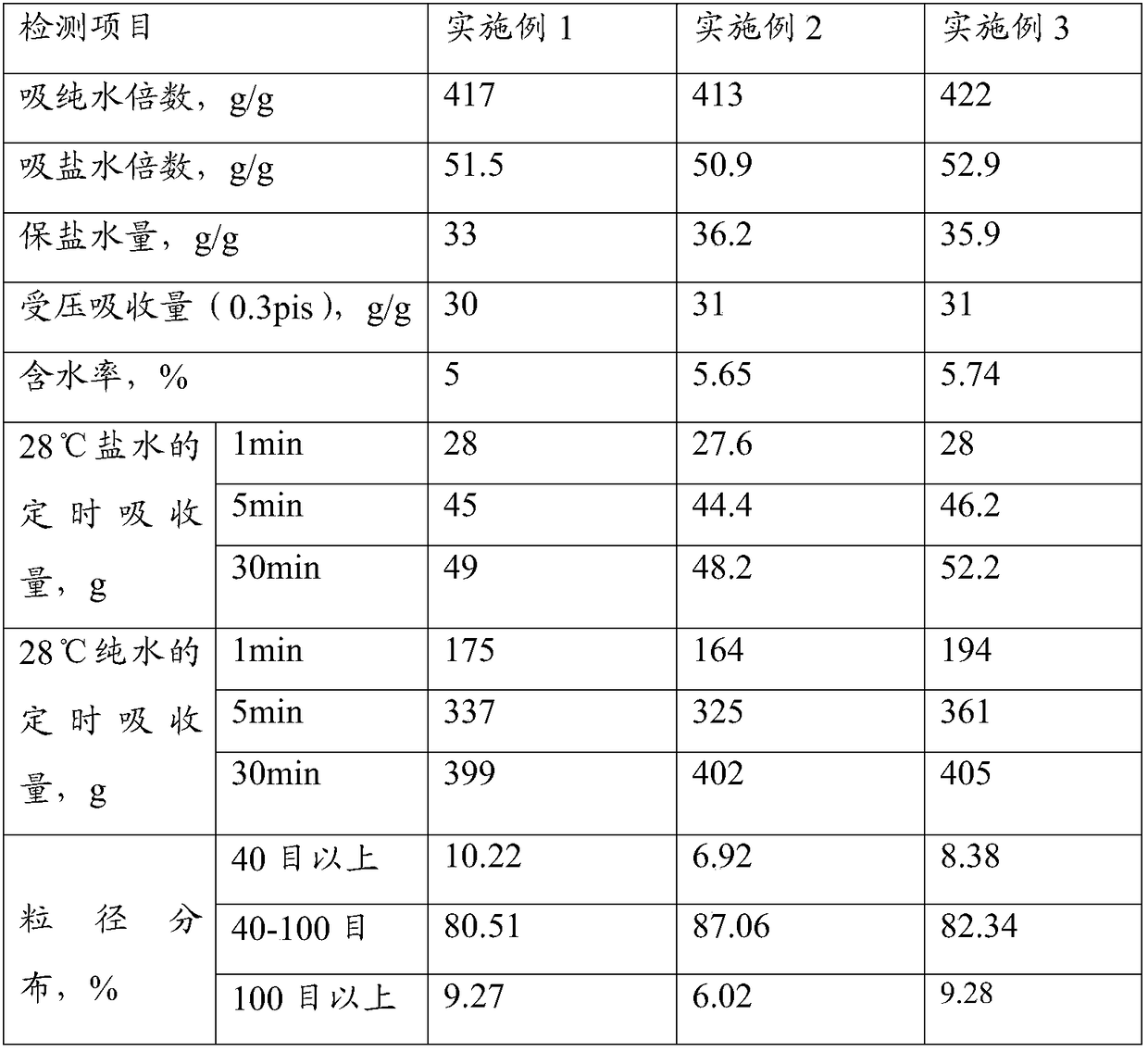

Embodiment 1

[0044] A superabsorbent resin, which is made of acrylic acid, acrylate or acrylic acid derivatives as polymerized monomers, neutralized with sodium hydroxide alkaline substance and deionized water, and then polymerized under the action of a composite crosslinking agent and an initiator A water-absorbent resin with a dense pore structure, the average pore diameter of the water-absorbent resin is 11.7 μm; wherein, the polymerized monomer is acrylic acid, and the composite crosslinking agent is glycerin and N, N'-methylenebisacrylamide Add according to the molar ratio of 1:2, the alkaline substance is sodium hydroxide; the dosage of each component is respectively:

[0045] Acrylic acid 25% (wt%),

[0046] Sodium hydroxide 25% (wt%),

[0047] Deionized water 48.845% (wt%),

[0048] Composite crosslinking agent 0.005% (wt%),

[0049] Ammonium persulfate 0.15% (wt%);

[0050] Concrete preparation method comprises the following steps:

[0051] 1) Neutralization: disperse acrylic...

Embodiment 2

[0060] A superabsorbent resin, which uses acrylic acid, acrylate or acrylic acid derivatives as polymerized monomers, neutralizes with alkaline substances and deionized water, and then polymerizes under the action of a composite crosslinking agent and an initiator to form dense pores. structure of water-absorbent resin, the average pore size of the water-absorbent resin is 10.9 μm; wherein, the polymerized monomer is acrylic acid, and the composite cross-linking agent is glycerin and N,N'-methylenebisacrylamide according to the molar ratio For adding in a ratio of 1:3, the alkaline substance is sodium hydroxide; the consumption of each component is respectively the consumption of the polymerized monomer, sodium hydroxide and deionized water in mass percent:

[0061] Acrylic acid 50% (wt%),

[0062] Sodium hydroxide 8% (wt%),

[0063] Deionized water 41.8% (wt%),

[0064] Composite crosslinking agent 0.05% (wt%),

[0065] Ammonium persulfate 0.15% (wt%);

[0066] Concrete p...

Embodiment 3

[0076] A superabsorbent resin, which uses acrylic acid, acrylate or acrylic acid derivatives as polymerized monomers, neutralizes with alkaline substances and deionized water, and then polymerizes under the action of a composite crosslinking agent and an initiator to form dense pores. Structured water-absorbent resin, the average pore size of the water-absorbent resin is 14.1 μm; wherein, the polymerized monomer is acrylic acid, and the composite cross-linking agent is glycerin and N,N'-methylenebisacrylamide according to the molar ratio For adding in a ratio of 1:2.5, the alkaline substance is potassium hydroxide; the consumption of each component is respectively the consumption of the polymerized monomer, sodium hydroxide and deionized water in mass percent:

[0077] Acrylic acid 50% (wt%),

[0078] Sodium hydroxide 20% (wt%),

[0079] Deionized water 34.94% (wt%),

[0080] Composite crosslinking agent 0.05% (wt%),

[0081] Ammonium persulfate 0.01% (wt%);

[0082] Concr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com