Sludge separating and filtering clarification tank and treatment process thereof

A treatment process and clarifier technology, applied in water/sludge/sewage treatment, water/sewage multi-stage treatment, chemical instruments and methods, etc., can solve the problems of numerous equipment and poor treatment effect, and avoid numerous process equipment , Reduce equipment, save operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

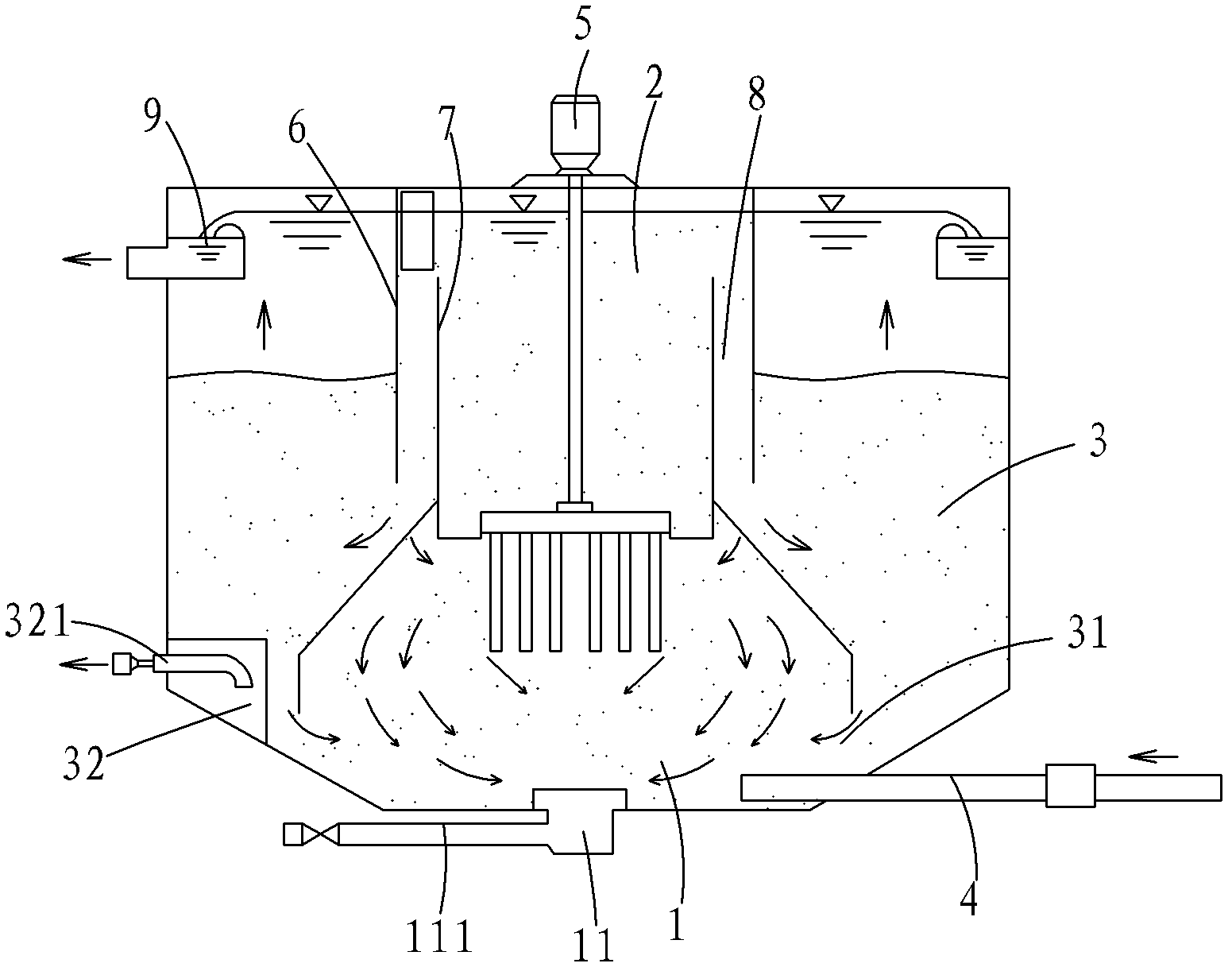

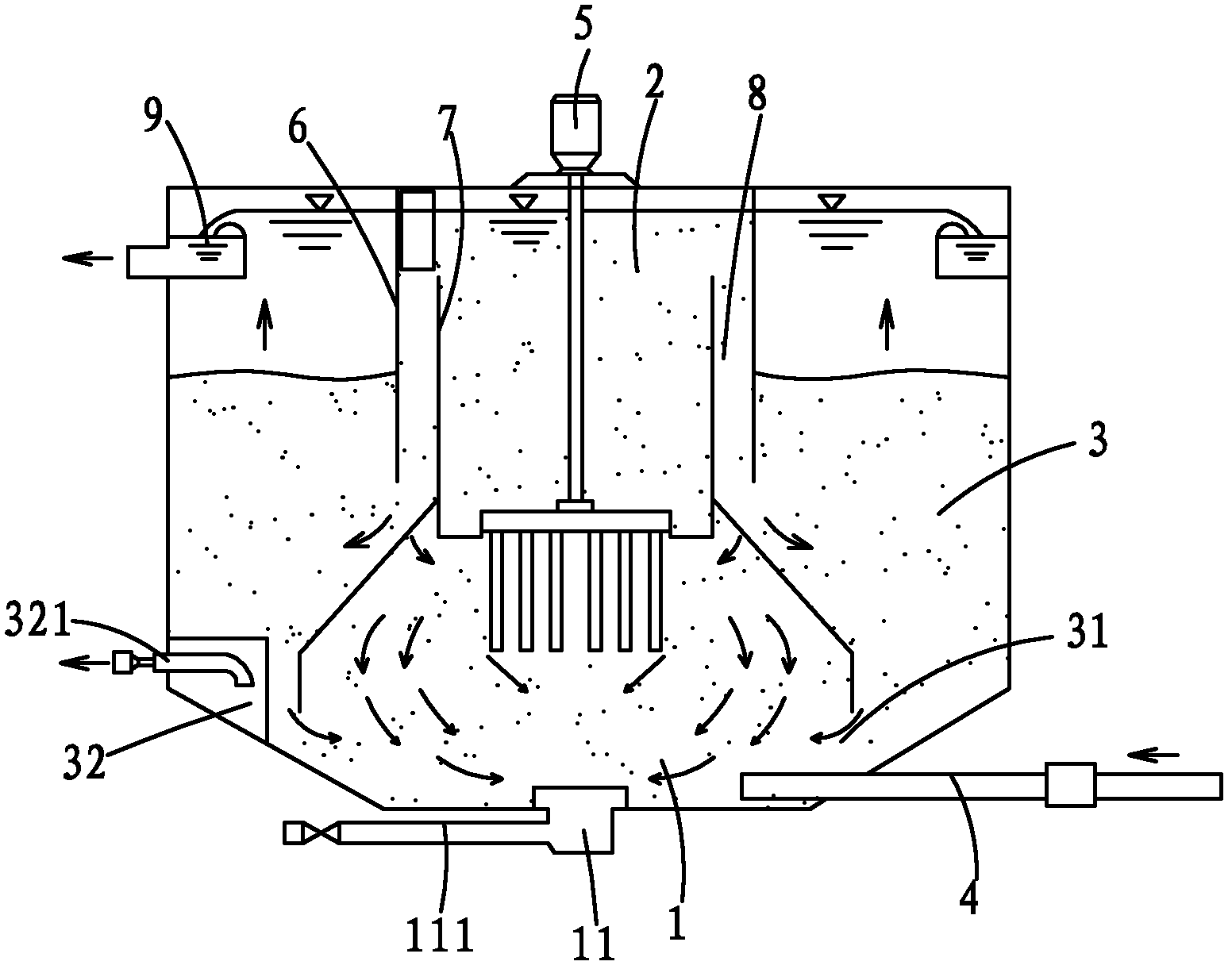

[0021] like figure 1 As shown, a sludge separation and filtration clarification tank involved in the present invention comprises a first reaction chamber 1, a second reaction chamber 2, a sludge separation chamber 3, a water inlet pipe 4 and a Agitator 5, the first reaction chamber 1 is connected below the second reaction chamber 2, the sludge separation chamber 3 surrounds the first reaction chamber 1 and the second reaction chamber 2 outside, the second reaction chamber 2 and A diversion chamber 8 separated by an upper deflector 6 and a lower deflector 7 is also provided between the sludge separation chambers 3, and the diversion chamber 8 is separated from the second reaction chamber 2 and the sludge. The chamber 3 communicates, and the sludge separation chamber 3 communicates with the first reaction chamber 1 through a return slot 31; the agitator 5 passes through the second reaction chamber 2 and reaches the first reaction chamber 1; the sludge The outer wall ring of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com