High-zinc-content mono-component epoxy anti-corrosive paint

An epoxy anti-corrosion coating, one-component technology, applied in the field of coatings, can solve the problems of inconvenient construction, zinc powder sedimentation, low metal zinc content, etc., and achieve the effect of good anti-corrosion effect and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

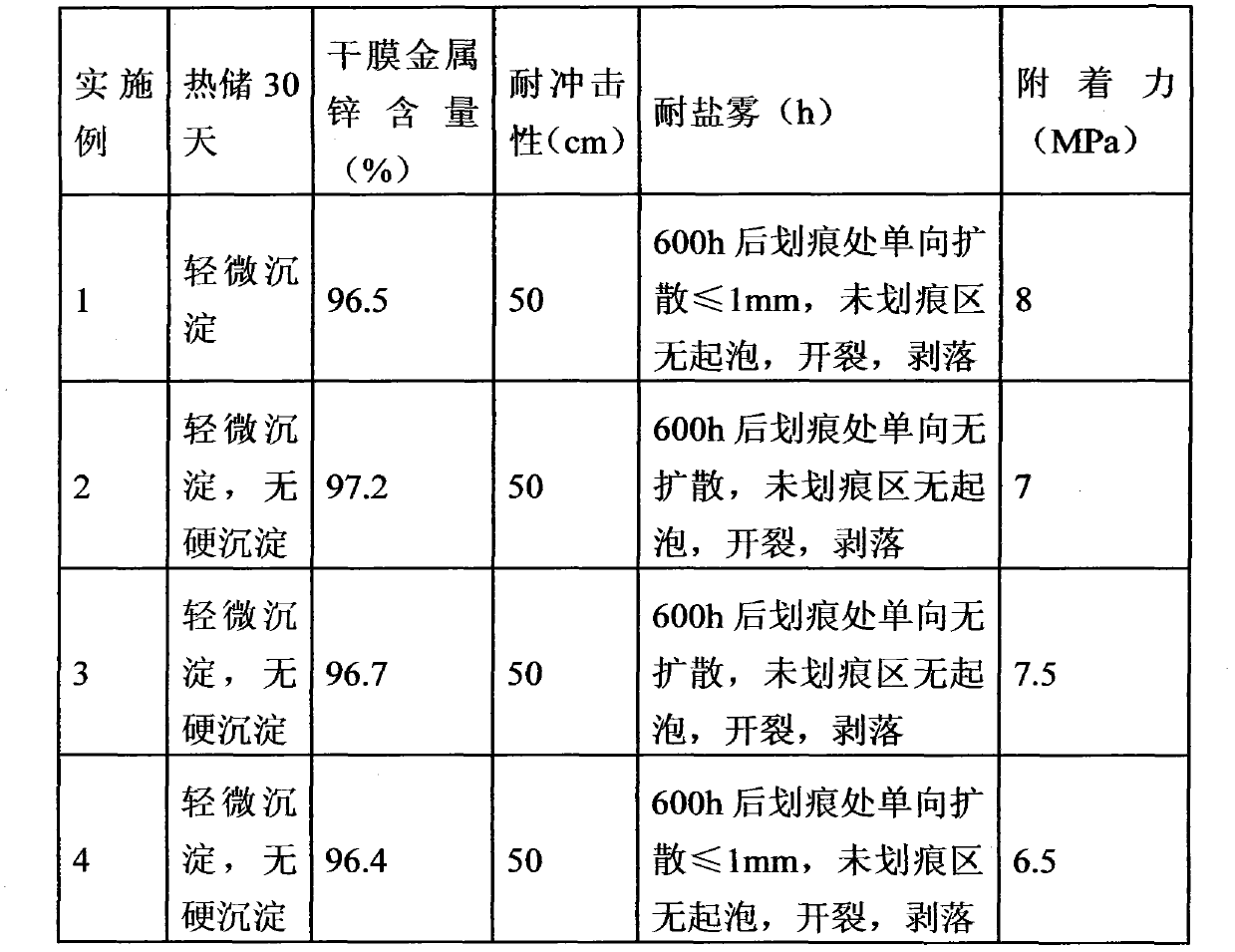

Examples

Embodiment 1

[0043] Add 10 parts of PMA solvent and 5 parts of modified epoxy resin 813 (Japan Mitsui) to the paint tank with cooling device, stir at 600 rpm for 10 minutes; continue to add 0.4 parts of wetting and dispersing agent P104S (BYK), 0.4 parts The antifoaming agent 810 (Jintuan Trade), 3 parts of activated organic bentonite slurry, stirred at 1000rpm for 15min; added 70 parts of zinc powder, increased the speed to 2000rpm, and stirred at high speed for 30min, during which circulating water was used to maintain the adjustment Cool the paint can, then reduce the speed to 1000rpm, add 0.8 parts of leveling agent, and continue to stir for 15 minutes. Reduce the rotation speed to 600rpm, stir for 10min, and then discharge and pack.

Embodiment 2

[0045] Add 15 parts of PMA solvent and 7 parts of modified epoxy resin 813 (Mitsui, Japan) to the paint tank with cooling device, stir at 600rpm for 10 minutes; continue to add 0.5 parts of wetting and dispersing agent P104S (BYK), 0.4 parts Defoamer keeper810 (Jintuan Trading), 0.2 parts of activated organic bentonite slurry and 0.5 parts of anti-settling agent 6900-hv (Disparon), stirred at 1000rpm for 20min; adding 120 parts of zinc powder, increased Speed up to 2500rpm, stir at high speed for 30 minutes, during this period, use circulating water to keep the paint tank cool, then reduce the speed to 1200rpm, add 0.5 parts of leveling agent, and continue stirring for 15 minutes. Reduce the rotation speed to 600rpm, stir for 15min, and then discharge and pack.

Embodiment 3

[0047] Add 18 parts of DAC solvent and 9 parts of modified epoxy resin 813 (Mitsui, Japan) to the paint mixing tank with cooling device, stir at 500 rpm for 10 minutes; continue to add 0.3 parts of wetting and dispersing agent P104S (BYK), 0.6 parts Antifoaming agent HX-2085 (Huaxia Pentium), 2 parts of anti-settling agent A630-20X (Disparon), stirring at 1000rpm for 20min; adding 120 parts of zinc powder, increasing the speed to 2500rpm, stirring at high speed for 30min, During this period, use circulating water to keep the paint mixing tank cool, then reduce the speed to 1500rpm, add 0.5 parts of leveling agent, and continue stirring for 15 minutes. Reduce the rotation speed to 600rpm, stir for 10min, and then discharge and pack.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com