Field sampling method of T/P92 steel ultra supercritical boiler tube

An ultra-supercritical boiler, on-site sampling technology, applied in sampling devices, preparation of test samples, etc., can solve the problems of material waste, pipeline damage, increase the time and cost of maintenance, and achieve the effect of simplifying sampling procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with embodiment.

[0025] The method for on-site sampling of T / P92 steel ultra-supercritical boiler pipelines of the present invention comprises the following steps:

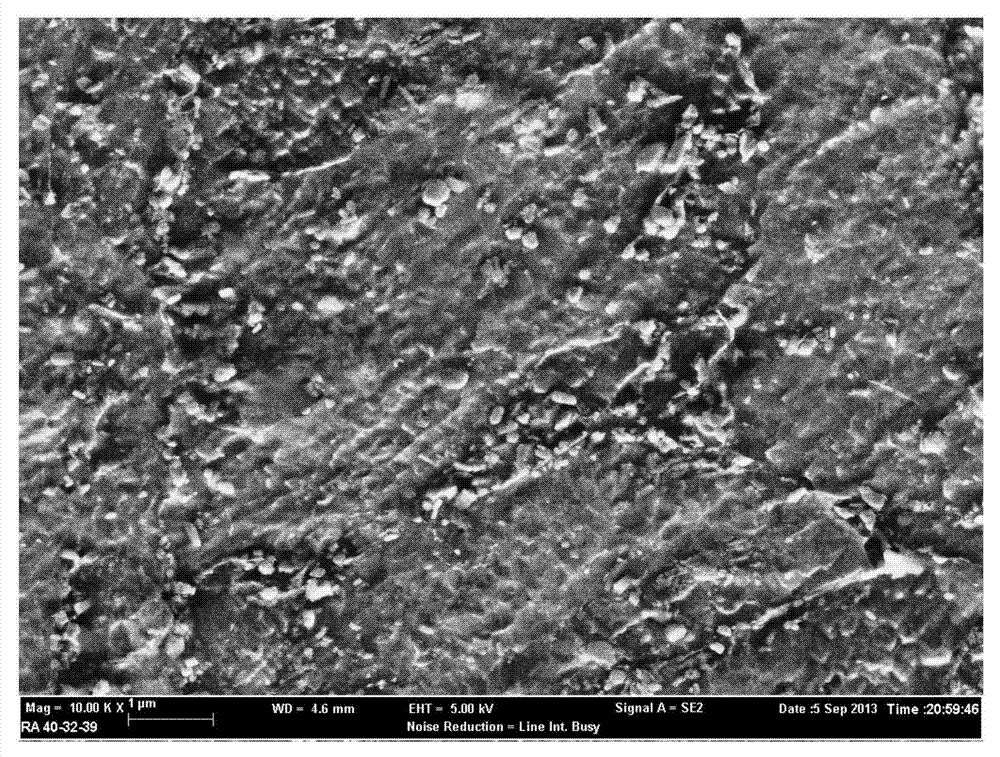

[0026] (1) Use a special high-speed steel or hard alloy cutter to dig out a piece of metal sheet with a size of 5mm*3mm*1mm for inspection at the place where the T / P92 steel ultra-supercritical boiler pipeline needs to be inspected.

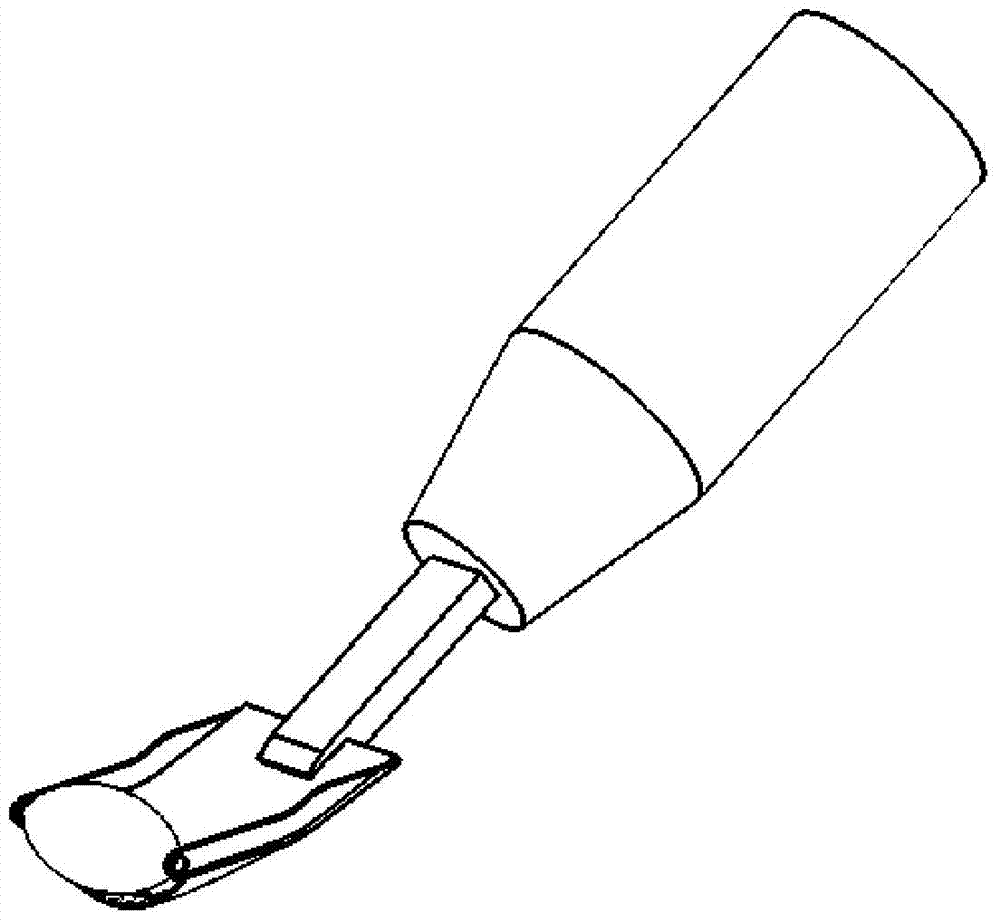

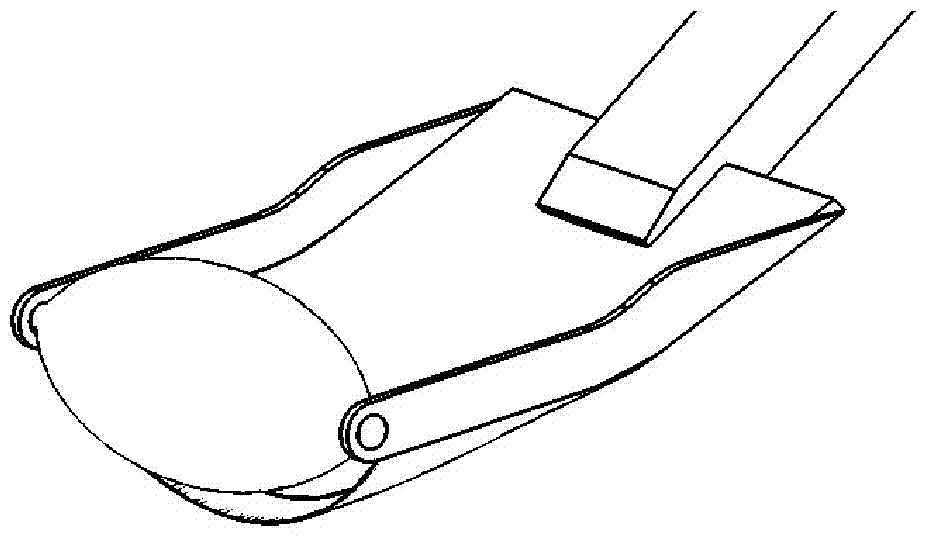

[0027] see figure 1 with figure 2 , The sampling tool is composed of a knife body and a knife handle. The knife body is composed of two independent parts: a carbide blade and a limit round roller. There is a circular hole at the upward bending place on both sides of the knife handle, which can rotatably support the shaft heads at both ends of the ellipsoid-shaped limiting round roller; the curvature radius of the knife edge is 30mm, and the curvature radius of the limiting ellipsoid-shaped roun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com