Method for preparation of phenolic resin by two-phase technique

A technology of phenolic resin and phenol, applied in the field of preparation of phenolic resin, can solve the problems of easily causing volatility, unfavorable rubber, loss of catalytic ability, etc., and achieves the effect of reducing moisture and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

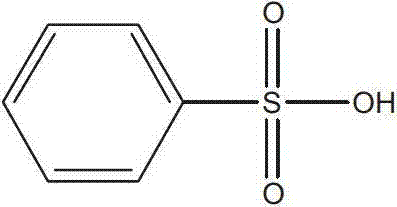

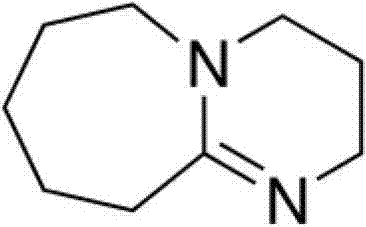

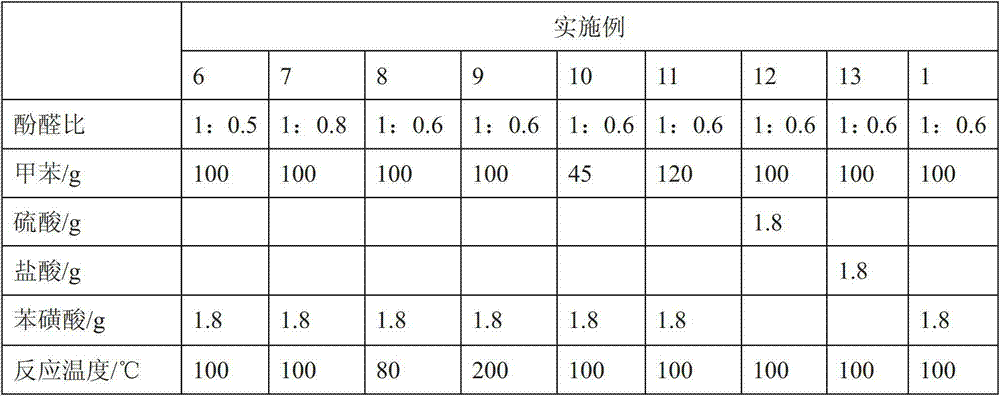

[0024] The preparation method of the present invention specifically comprises: in a four-necked flask equipped with a stirring device, an electric heating temperature control device and a reflux condenser, add about 100-200 g of toluene solvent, then add 100-200 g of phenol, and 37% of Formaldehyde 50~100g, heat up to 100°C. And add 0.5-5g of benzenesulfonic acid catalyst, reflux reaction for 1-3h, after the reaction, raise the temperature to 130-150°C, carry out atmospheric distillation for 1h, remove excess water and solvent, add organic amines The terminator is used to terminate the reaction. In this experiment, 1,8-diazabicyclo[5.4.0]undec-7-ene (abbreviated as DBU) was used to terminate the reaction. Its structural formula is as follows to obtain the product phenolic resin.

[0025]

Embodiment 1

[0027] Add 100g of toluene, 150g of phenol and 1.8g of benzenesulfonic acid into a 500ml four-neck flask, raise the temperature to 100°C and start stirring slowly, then slowly add 20g of 37% liquid aldehyde to the system dropwise for 30min; Then slowly add 13.5g of solid aldehyde, and finish adding in 30 minutes; finally add 26.7g of liquid aldehyde dropwise, and finish adding dropwise within 30 minutes. The system is milky white. Reflux reaction at 100°C for 1 hour, then increase the temperature to 130°C, remove water and toluene respectively, the solution gradually changes from milky white to light red or dark red, until no substance comes out from the distillation reaction, add 0.64g DBU, there will be a lot of white Fog is formed, stir for 5-10 minutes, stop stirring and discharge to obtain a reddish-brown solid.

Embodiment 2

[0031] Add 100g of toluene, 150g of phenol and 1.8g of benzenesulfonic acid into a 500ml four-neck flask, raise the temperature to 100°C and start stirring slowly, then slowly add 20g of 37% liquid aldehyde to the system dropwise for 30min; Then slowly add 13.5g of solid aldehyde, 30min after the addition is complete, after the reflux reaction, a large amount of foam will be generated, which is caused by the water reflux reaction in the system, and the system becomes milky white. Finally, 26.7 g of liquid aldehyde was added dropwise, and the same dropwise addition was completed within 30 minutes. Reflux at 100°C for 1 hour, then increase the temperature to 150°C, remove water and toluene respectively, the solution gradually changes from milky white to light red or dark red, until no substance comes out from the distillation reaction, add 0.64g DBU, there will be a lot of white Fog is formed, stir for 5-10 minutes, stop stirring and discharge to obtain a reddish-brown solid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com