Ethanol replacement oil preparation method and equipment for ethanol replacement oil preparation method

A technology of ethanol and equipment, which is applied in the field of ethanol replacement oil production method and its equipment, can solve the problems of high energy consumption and unguaranteed quality, and achieve the effects of oil product quality assurance, solvent turnover reduction, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Ethanol replacement oil production method, the steps are as follows: a. Use ethanol solution with a concentration greater than 95% and a temperature higher than its boiling point as a solvent to infiltrate the cake; b. The cake soaked with the ethanol solution is heated to 120°C by friction and pressure. Fully miscible with the oil in the cake; c. Squeeze to separate the mixed oil for desolventization.

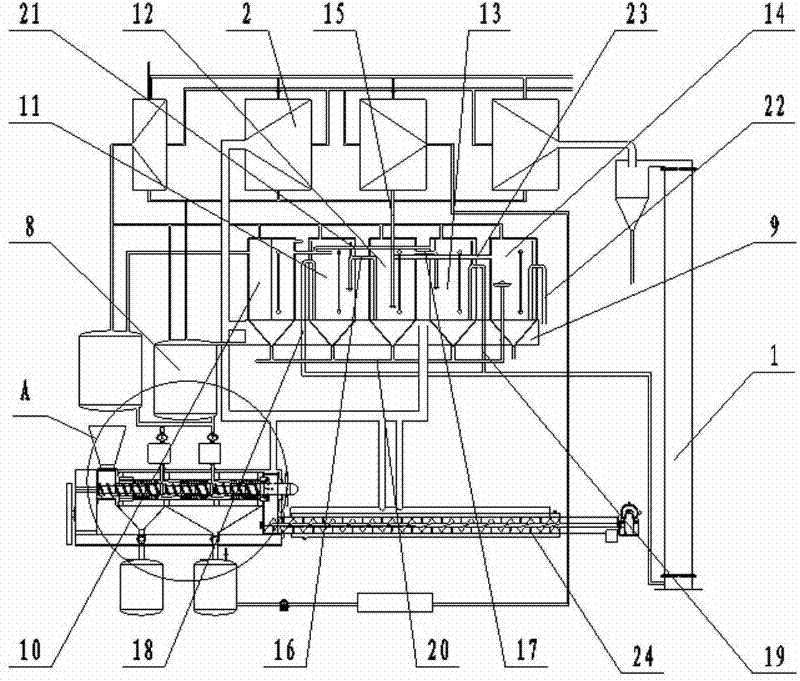

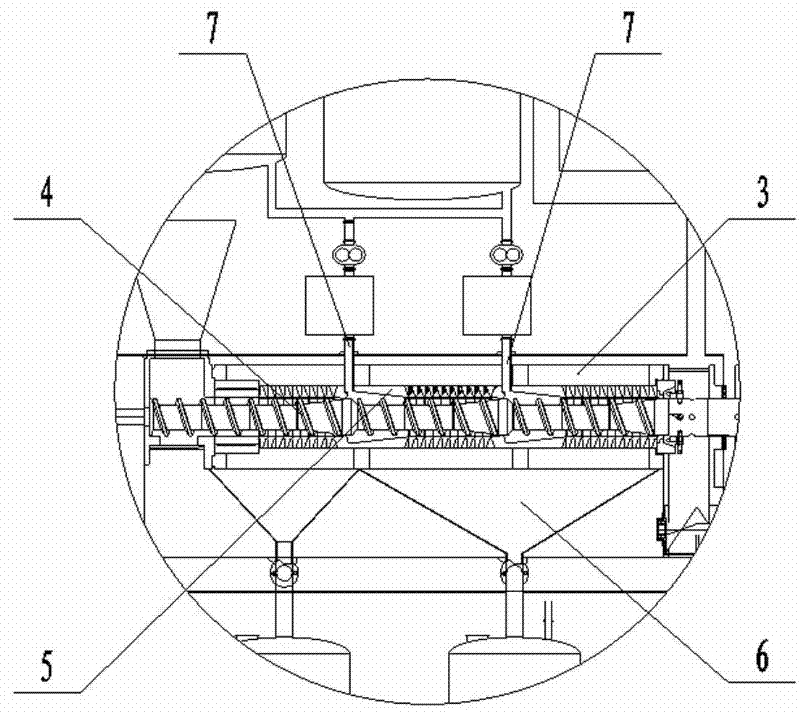

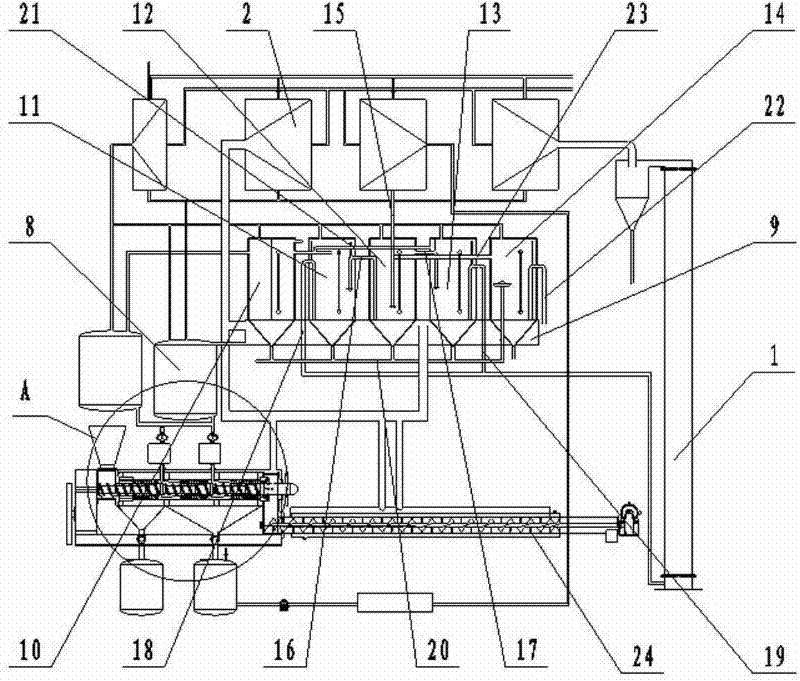

[0016] The ethanol replacement oil production equipment includes an evaporator 1, a condenser 2, and an oil press and a separator. The oil press includes a press cage 3 and a press snail coaxial therein and coaxial with it. The press snail is composed of several joints The squeeze screw body 4 is composed of a squeeze screw body 4 whose internal diameter gradually increases. The front part of the squeeze screw body 4 in the second section and thereafter is covered with an infiltration sleeve 5 whose inner diameter gradually decreases backward, and the squeeze screw body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com