Tinder trapping and heat energy recovery device for flue gas of steelmaking converter

A technology for steelmaking converters and heat recovery, applied in furnaces, furnace components, waste heat treatment, etc., can solve the problems of poor system safety, low steam quality, high failure rate, etc., achieve stable and reliable work, simple structure, and improve heat exchange efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited in any way. Any changes or improvements made based on the teaching of the present invention belong to the protection scope of the present invention.

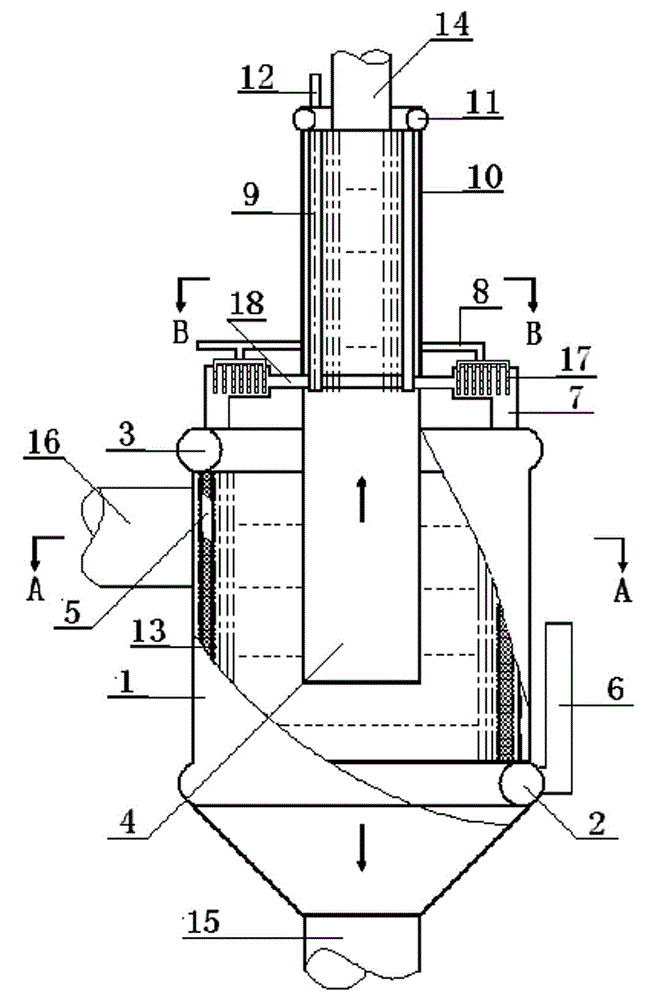

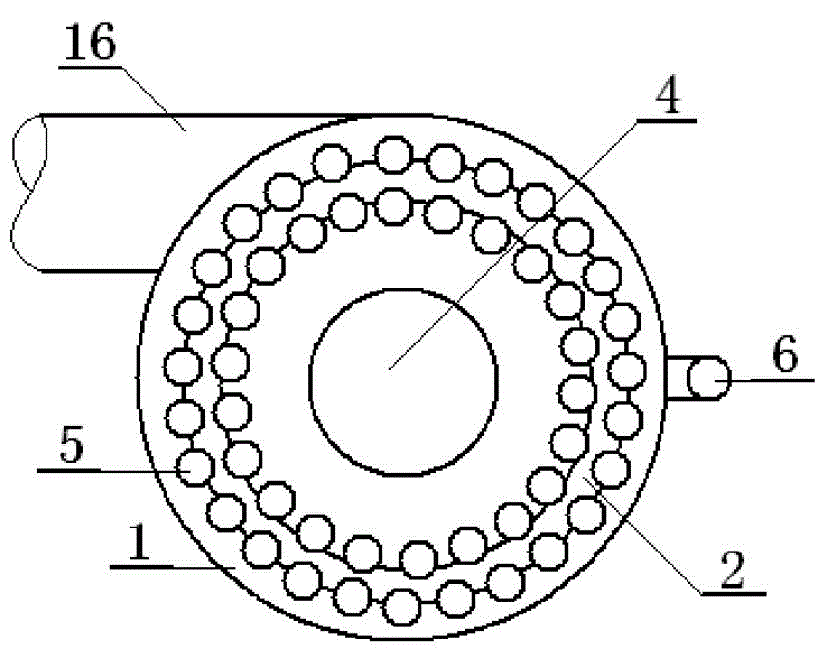

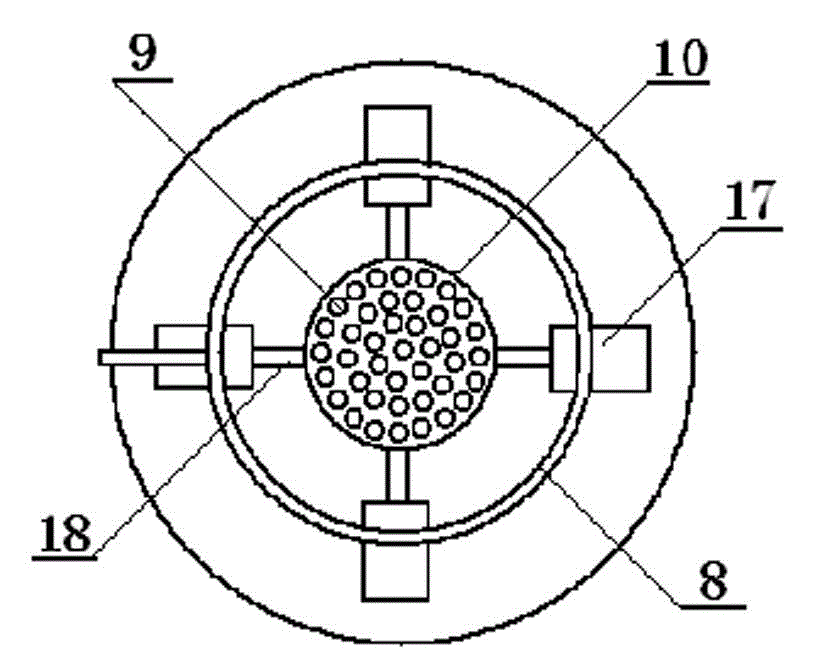

[0011] like figure 1 As shown, the device of the present invention includes a primary superheater 1 and a secondary superheater 10, the bottom of the primary superheater 1 is provided with a dust removal port 15; the primary superheater 1 is a shell structure, and the lower guide The liquid ring 2 and the upper liquid guide ring 3 are provided with a smoke guide pipe 4 in the center; the liquid guide rings are connected through the water guide pipe 5, and the lower liquid guide ring 2 is provided with a water inlet pipe 6; the above-mentioned secondary superheater 10 is provided with an air guide pipe Bundle 9, the upper part communicates with air guide ring 11, and superheated stea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com